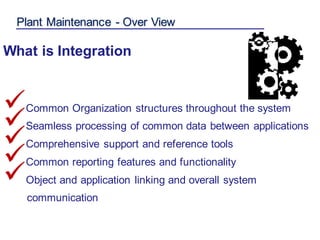

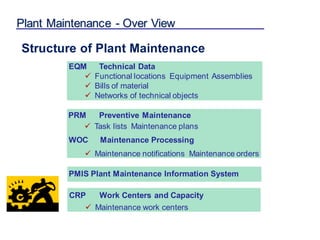

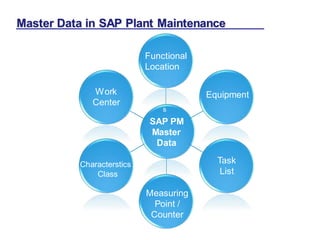

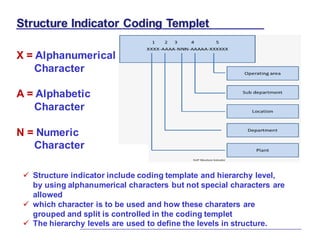

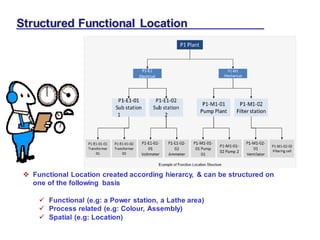

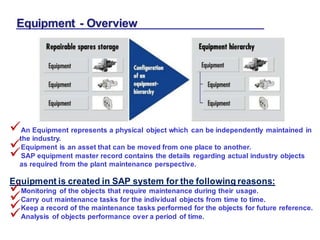

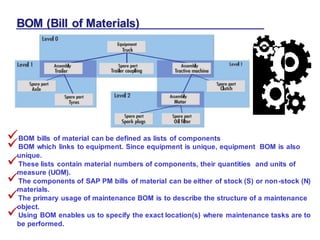

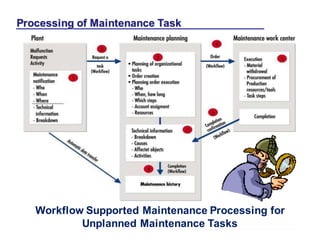

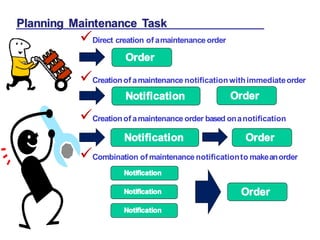

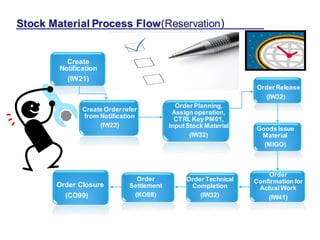

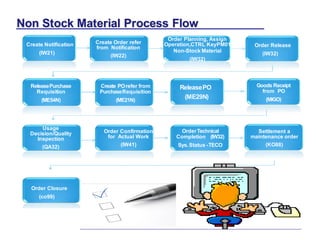

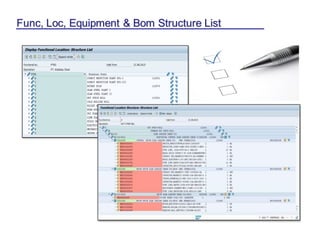

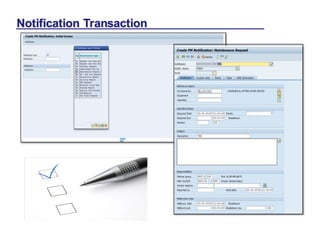

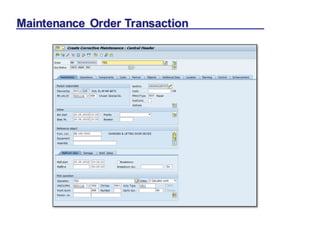

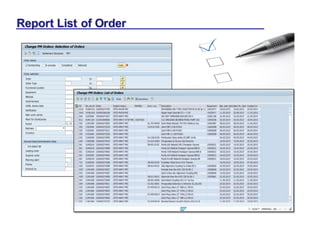

This document provides an overview of SAP Plant Maintenance. It describes the integration of plant maintenance with other SAP modules. It discusses the organization of plant maintenance and benefits such as increased productivity and reduced downtime. It also summarizes key plant maintenance concepts like functional locations, equipment, bills of material, work centers, and the processes for planned and unplanned maintenance.