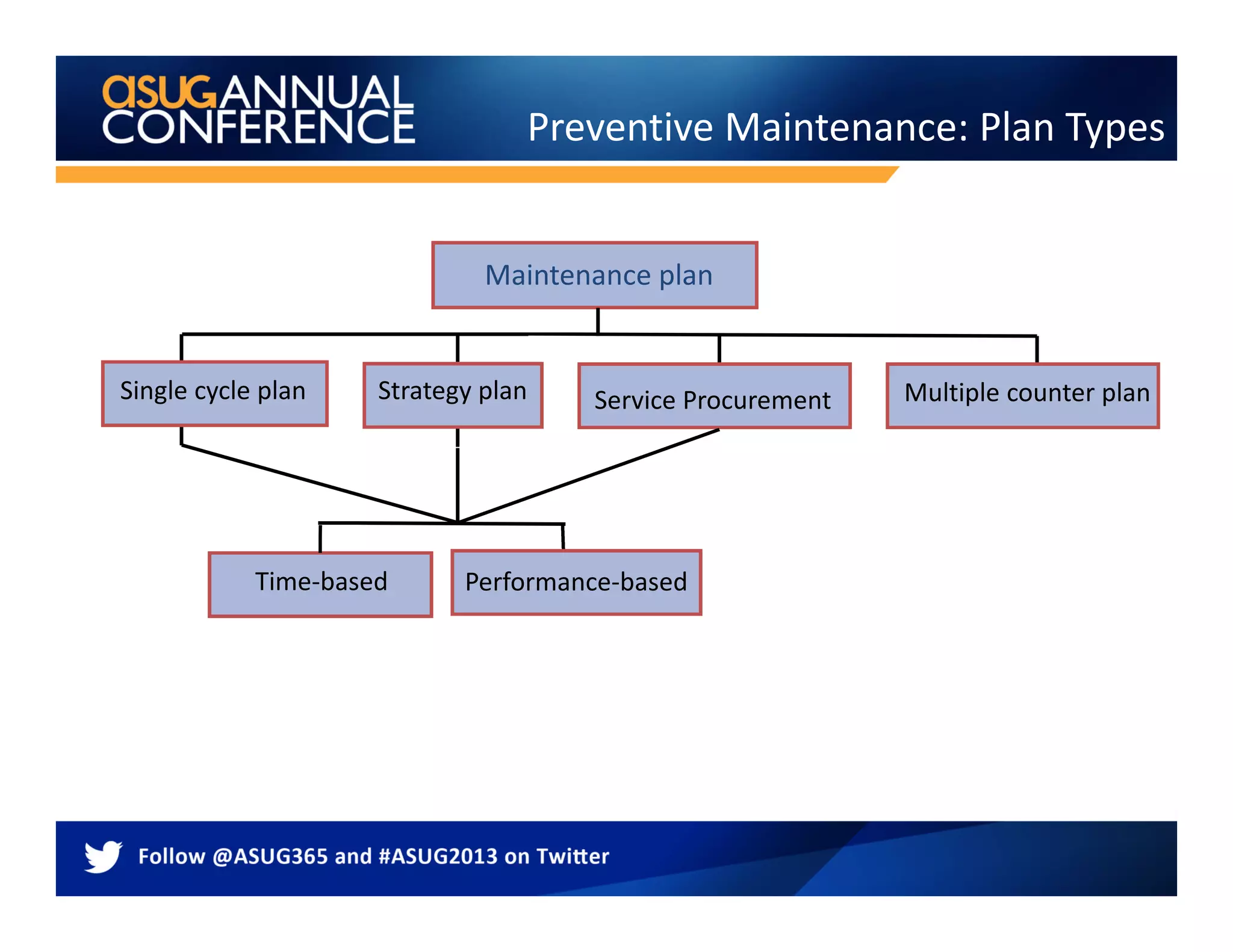

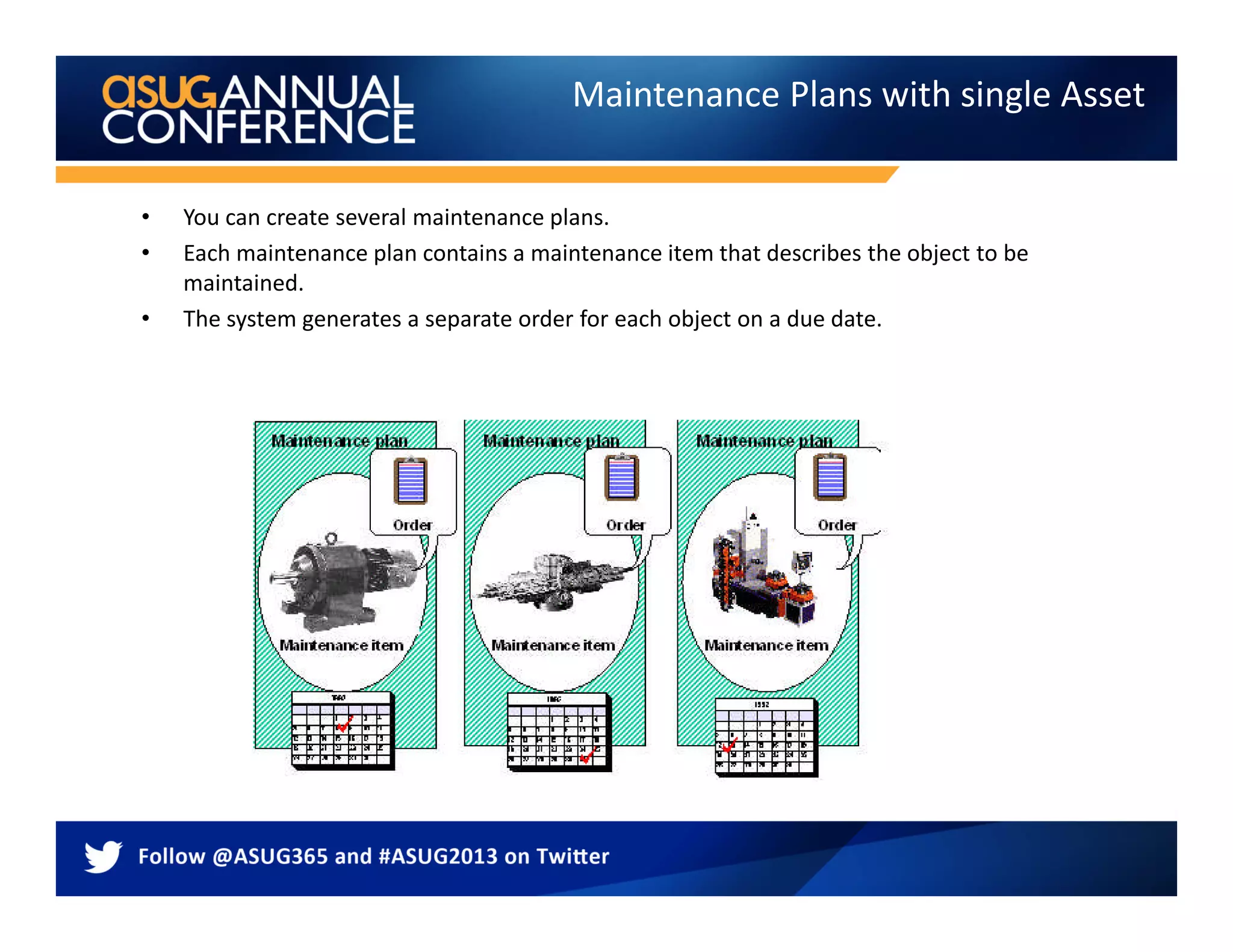

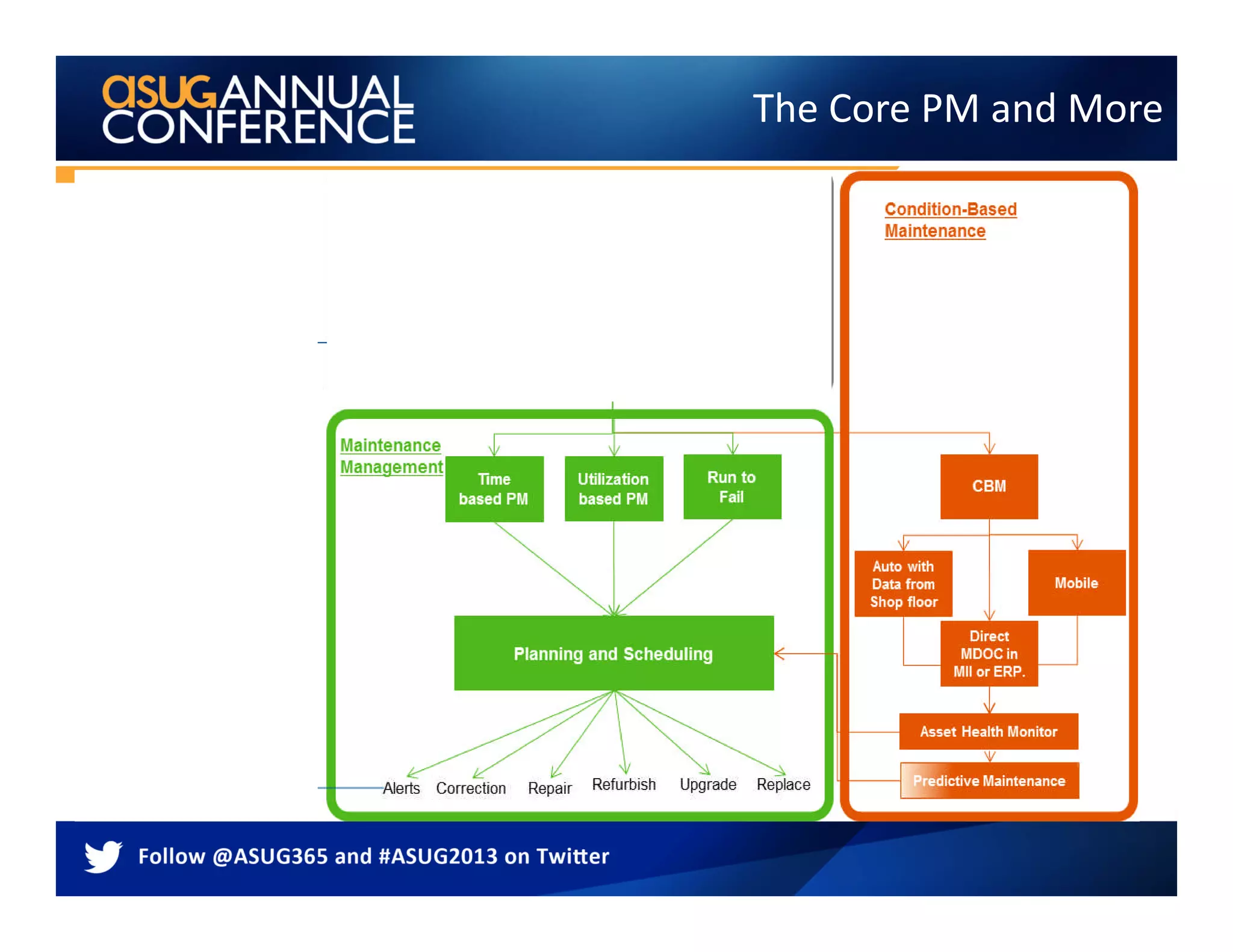

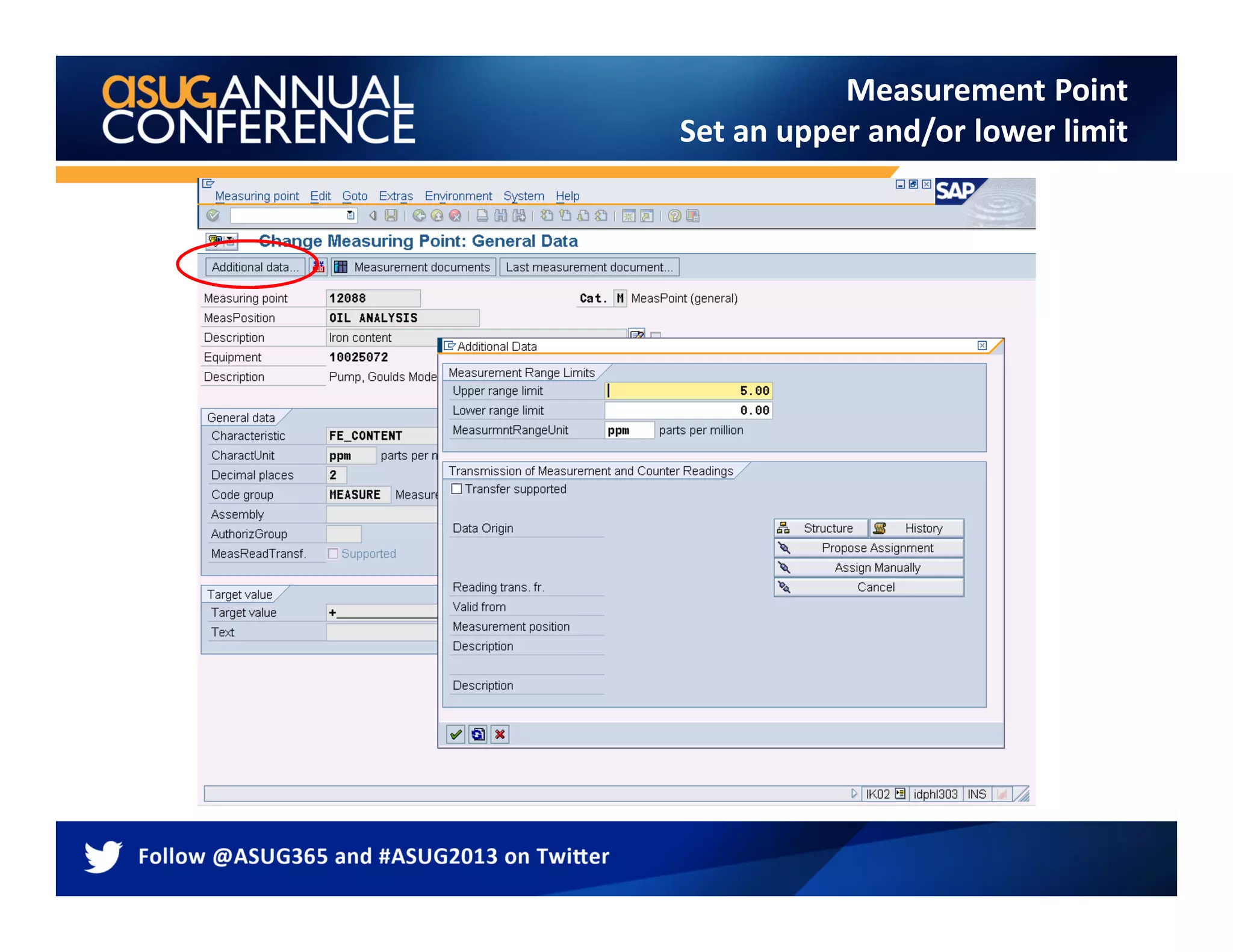

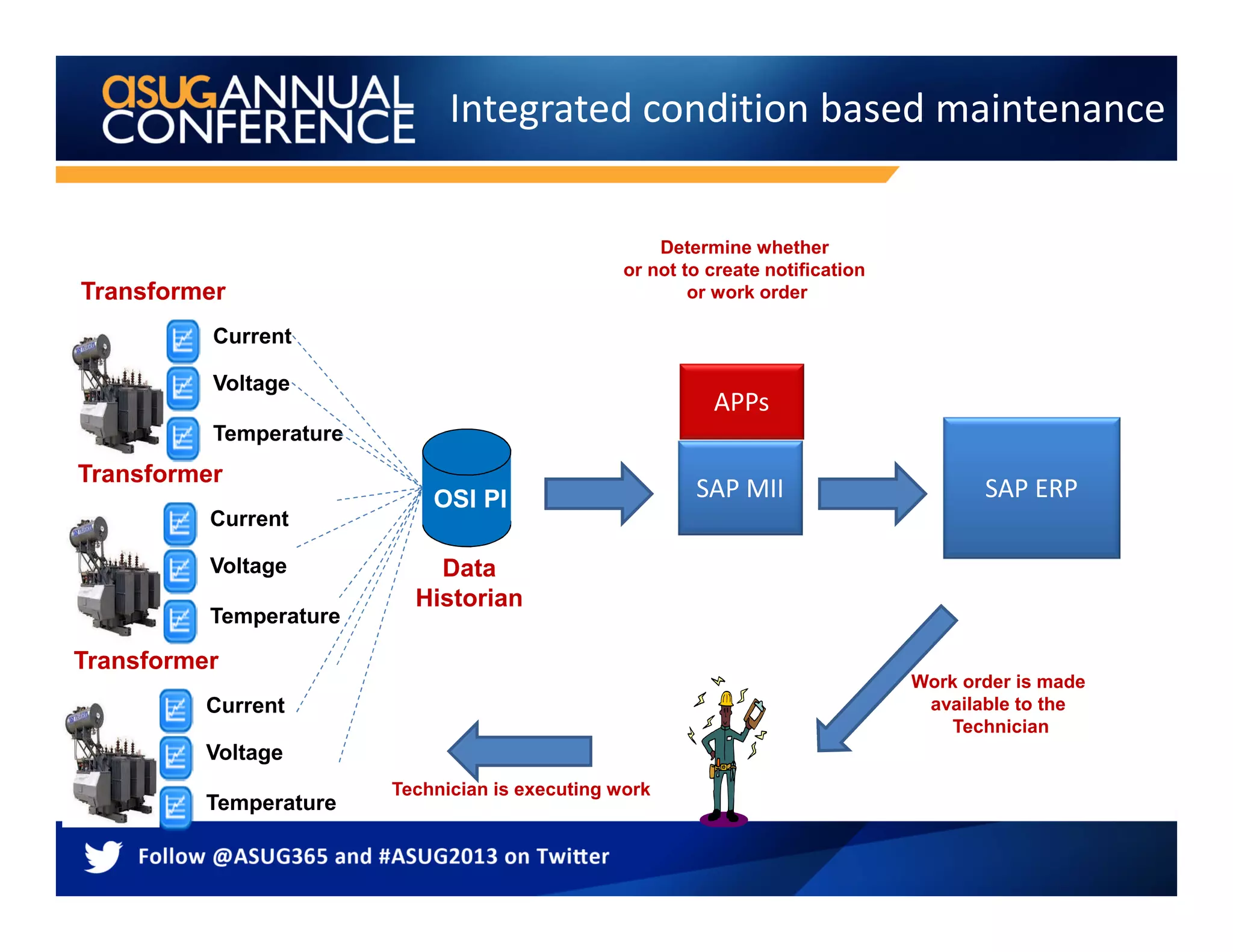

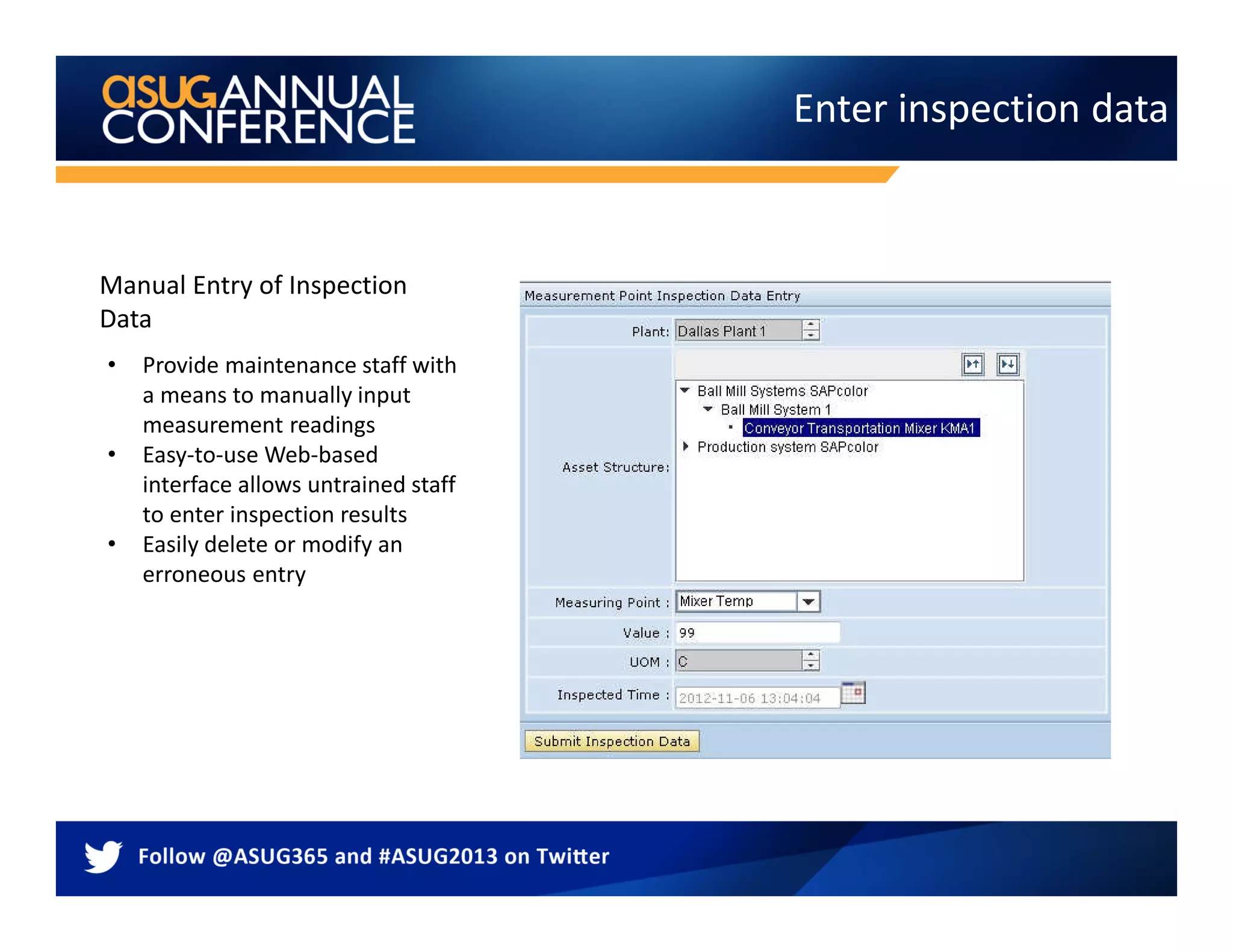

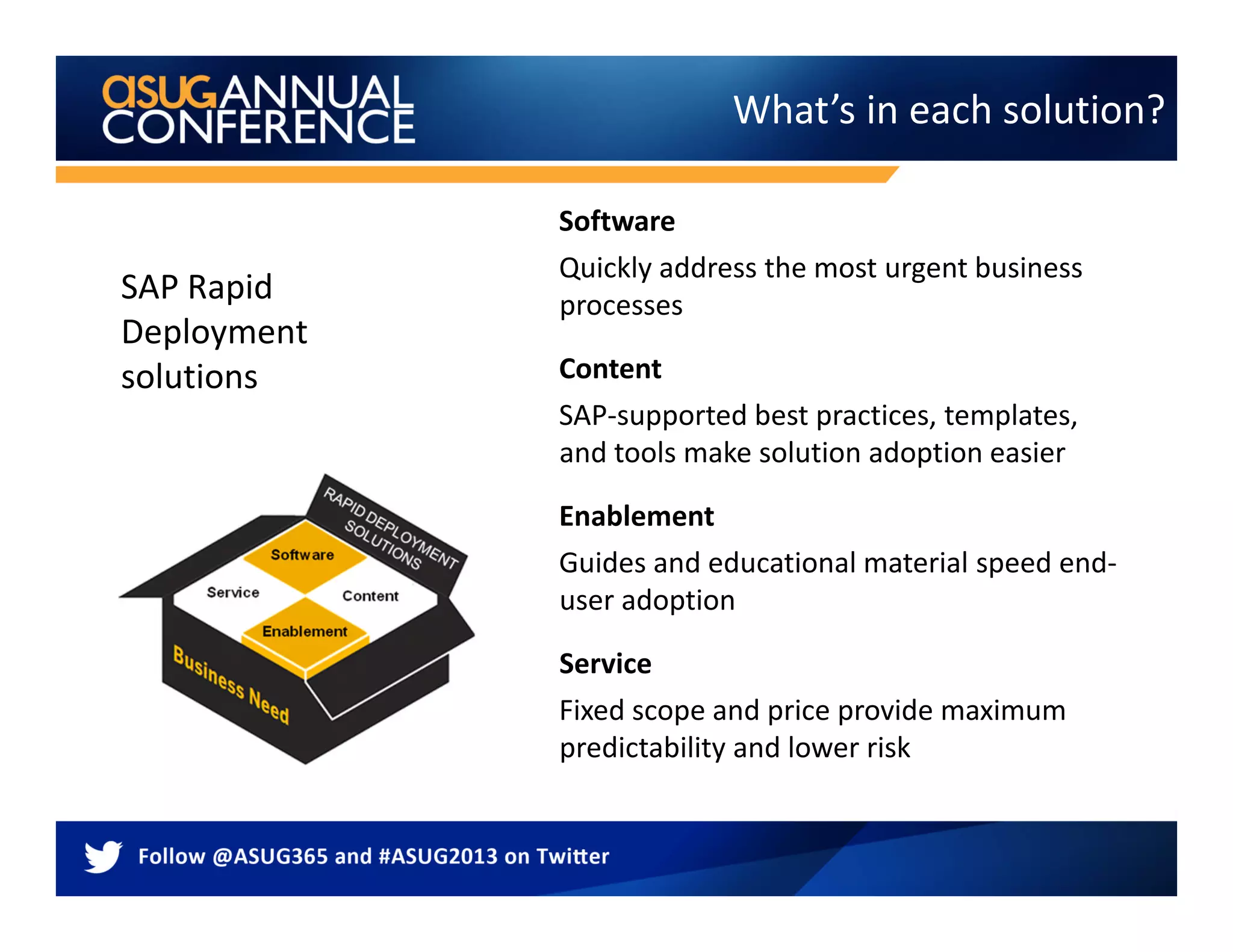

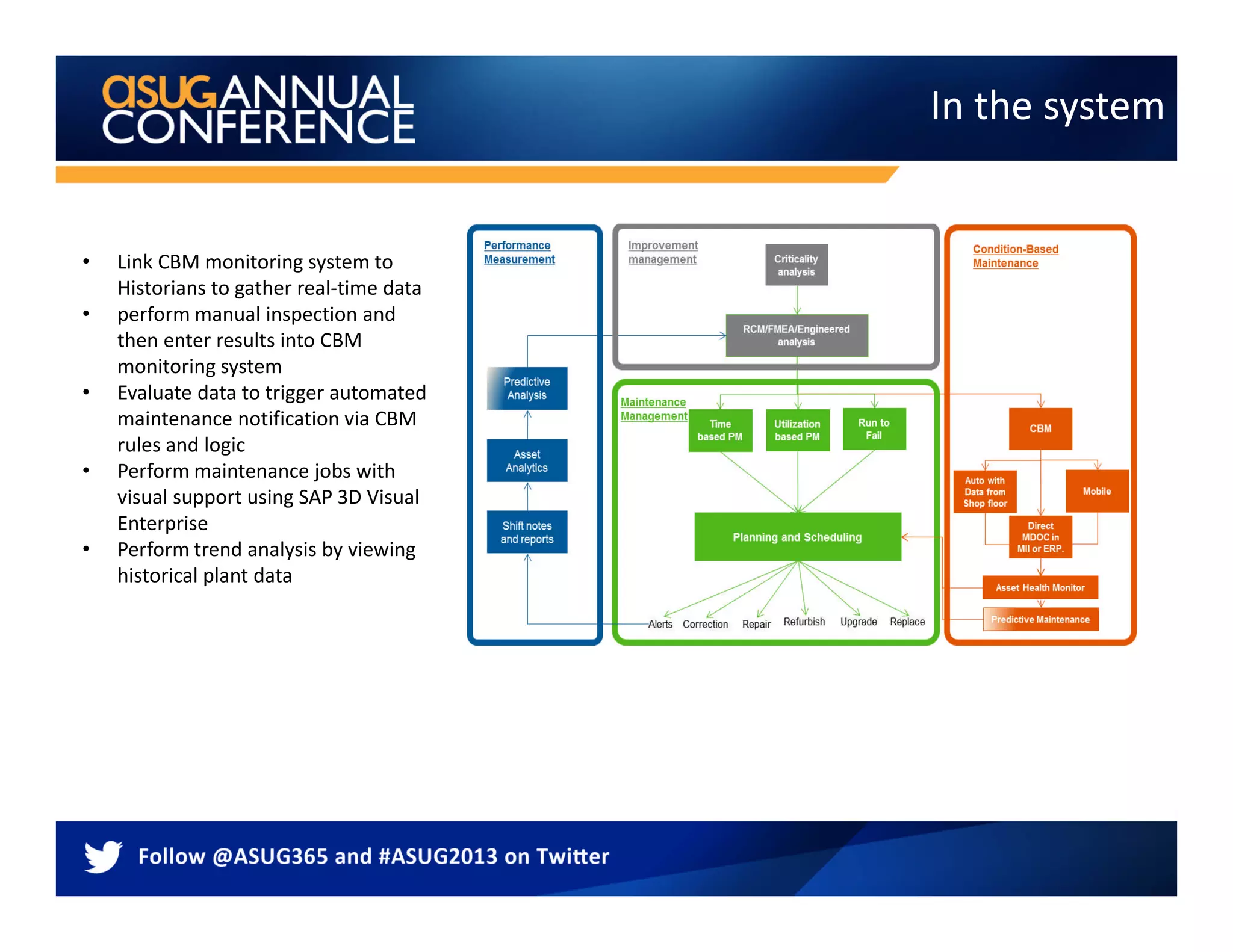

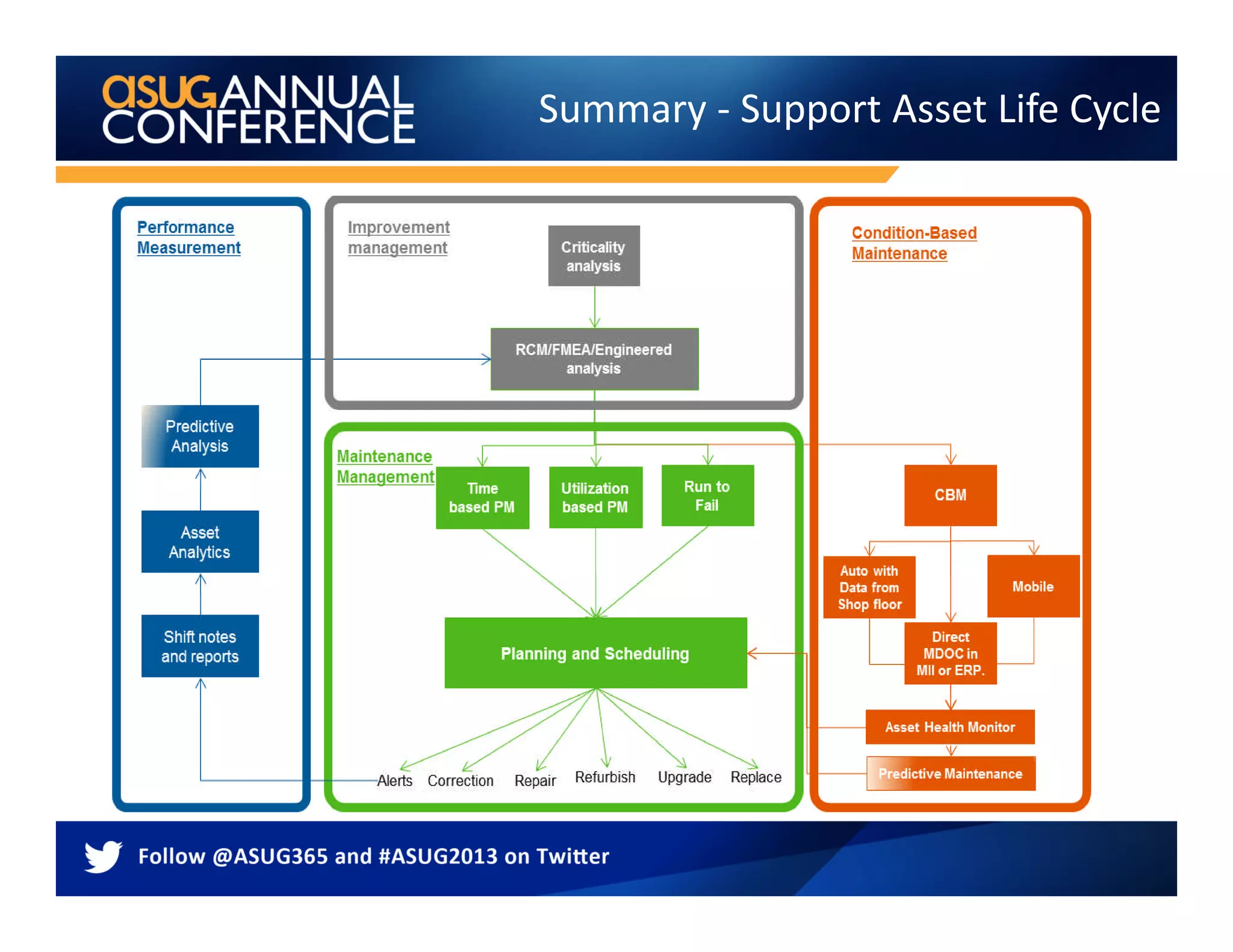

The document discusses SAP's preventive maintenance and condition-based maintenance capabilities. It covers the core functions of setting up preventive maintenance plans based on time, performance, or condition. It also discusses using "light" condition-based maintenance capabilities in SAP to monitor asset health parameters and trigger maintenance workflows. Finally, it presents SAP's rapid deployment solution for condition-based maintenance which provides asset health dashboards, manual/automatic triggering of maintenance from sensor data, and integration with SAP EAM.