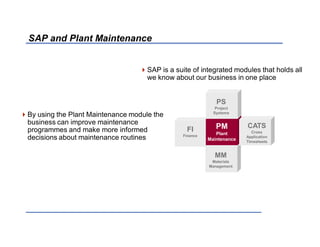

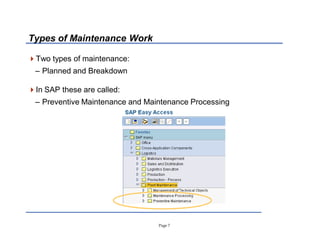

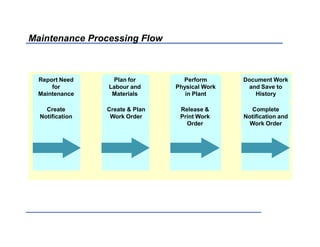

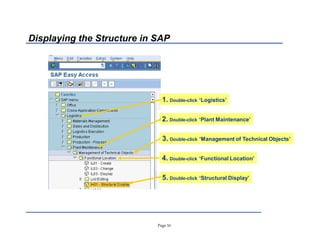

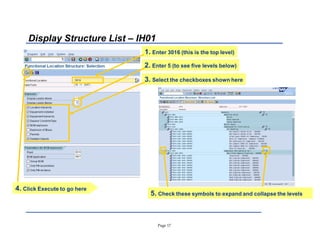

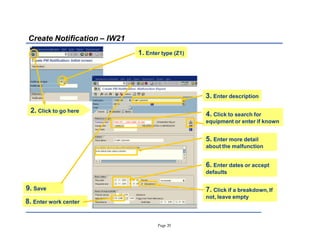

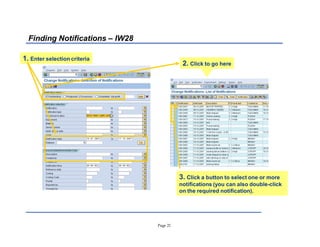

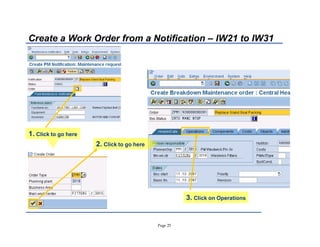

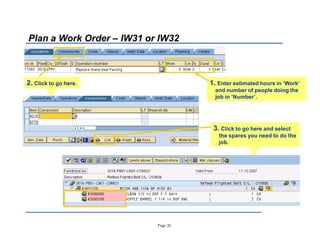

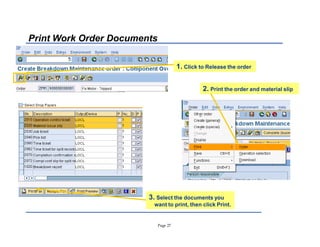

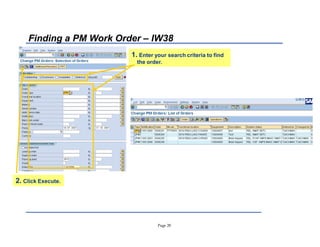

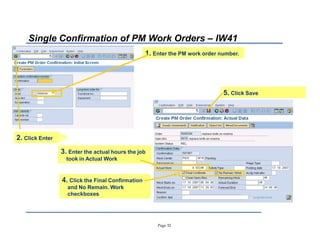

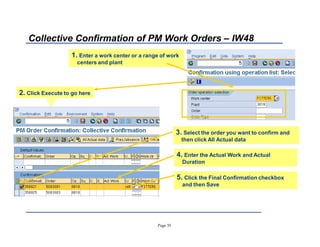

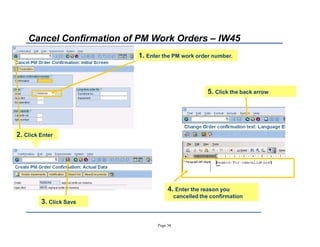

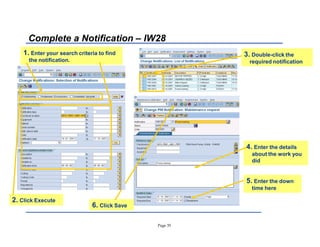

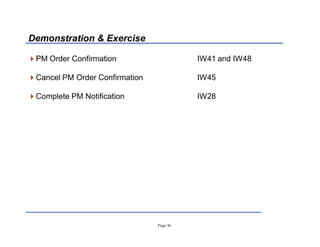

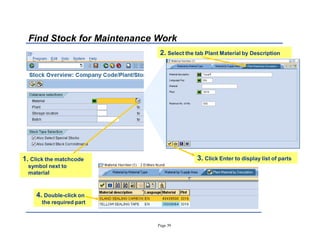

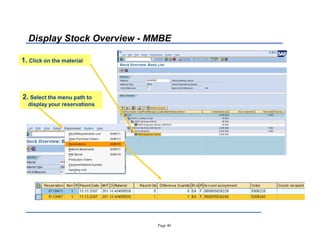

This document provides an agenda and objectives for a plant maintenance course in SAP for engineering staff. The agenda includes creating notifications and work orders, confirming work orders, and viewing stock. The objectives are to understand SAP plant maintenance terminology and processes and be able to perform tasks like creating a notification, viewing stock, and confirming a work order. The document then provides step-by-step instructions and screenshots for how to perform these tasks in SAP.