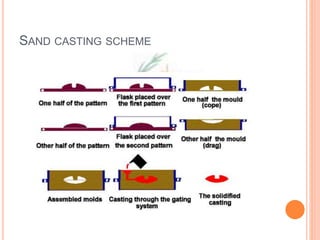

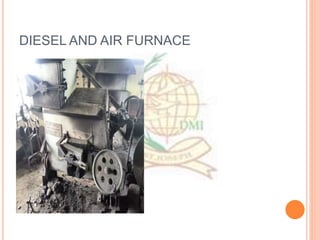

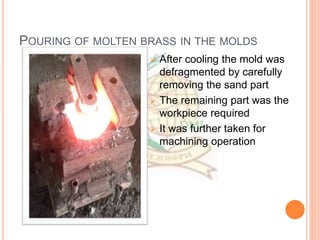

The document discusses the student's training report on mechanical workshop activities at Tanganyika Planting Company (TPC) Ltd, a sugar company in Tanzania. It describes TPC's history and operations. It then details the processes of pattern design, mold making with sand casting, melting brass, and pouring the molten metal into molds to produce castings. The student learned new technical skills like machining, metal fabrication, pattern design, and molding during the training.