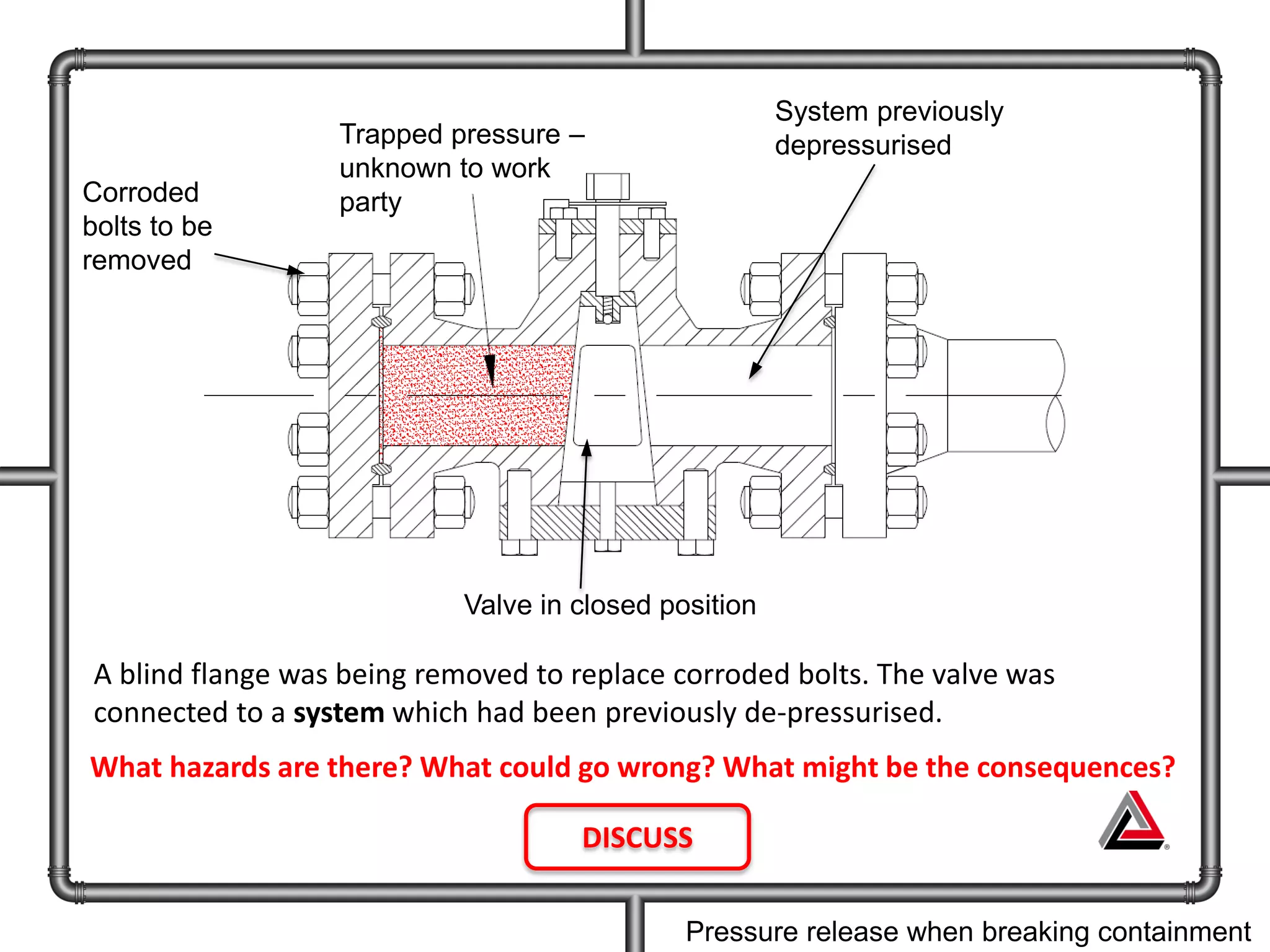

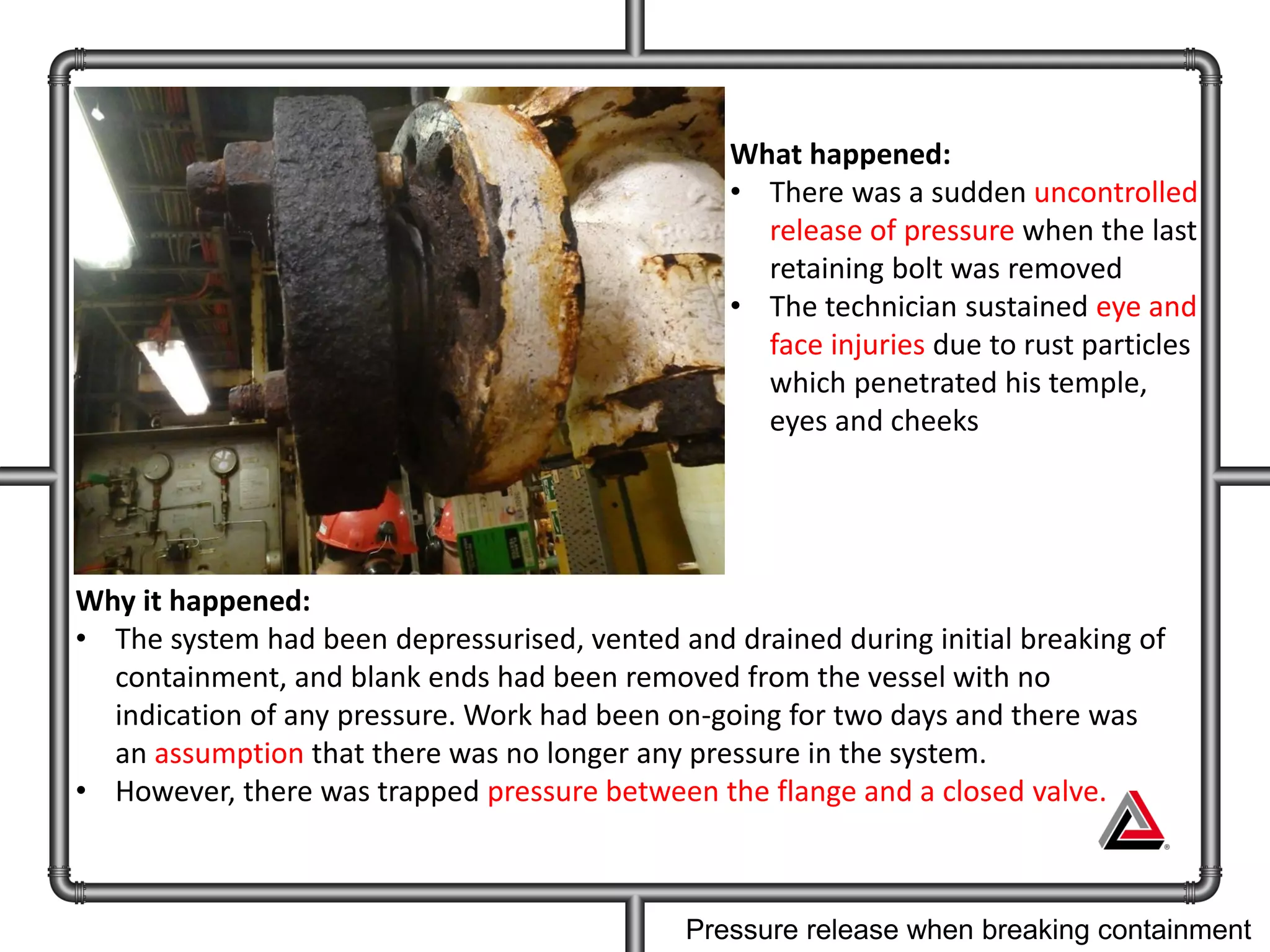

This safety moment emphasizes the risks associated with pressure release during the breaking of containment, highlighted by an incident where a technician sustained injuries from an uncontrolled release of pressure due to trapped pressure misconceptions. Key preventative measures include training staff on recognizing possible trapped pressure, ensuring proper monitoring during containment breaks, and avoiding complacency. The document identifies crucial behaviors and procedures necessary for safety, linking them to the 7 Cs of safety management.