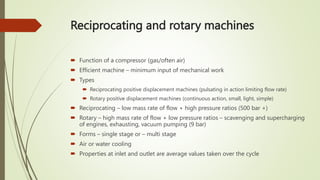

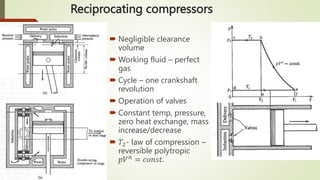

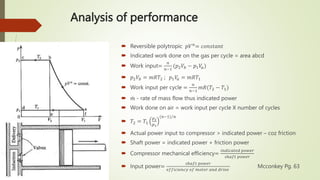

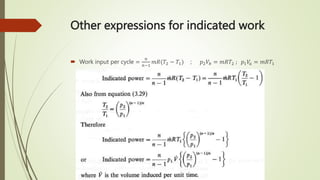

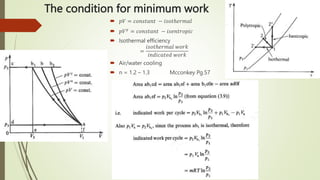

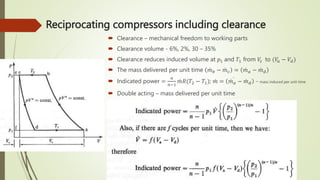

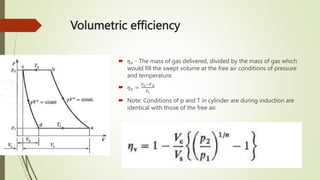

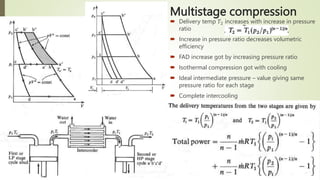

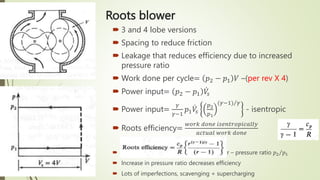

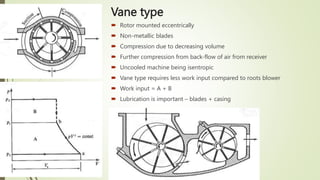

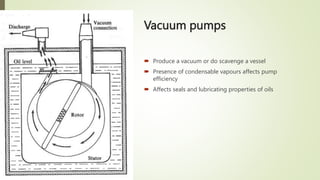

This document discusses positive displacement machines, specifically reciprocating and rotary compressors. It describes the basic functions and types of positive displacement machines, including reciprocating compressors which have low flow rates but high pressure ratios, and rotary compressors which have continuous flow but lower pressure ratios. The document provides analysis of compressor performance in terms of indicated work, actual power input, efficiency, and volumetric efficiency. It also covers topics such as multi-stage compression, intercooling, and the operation of rotary machines like roots blowers and vane compressors.