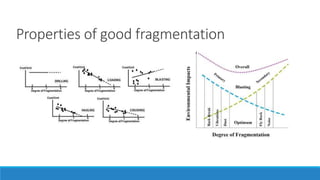

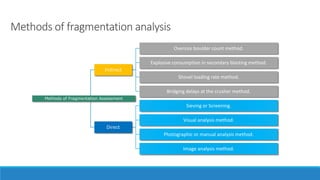

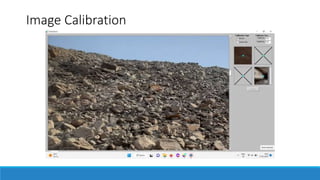

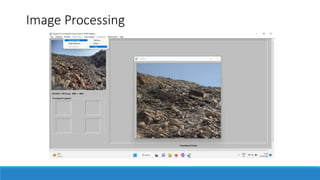

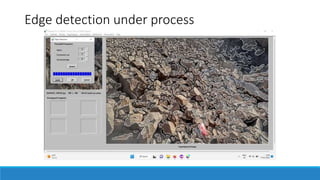

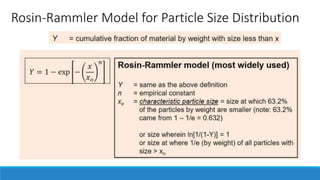

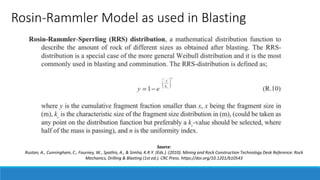

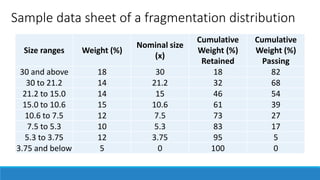

The document discusses rock fragmentation analysis using granulometric software, focusing on the properties and optimization of rock fragmentation achieved through blasting operations. It explores quantification methods such as mean fragment size and various fragmentation assessment methods, including both direct and indirect techniques. The WipFrag software is highlighted for its ability to analyze digital images of muck piles, applying advanced image processing techniques for effective fragmentation assessment.