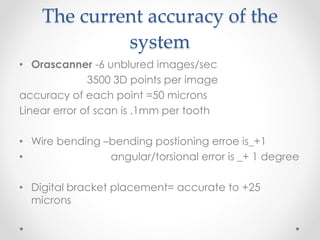

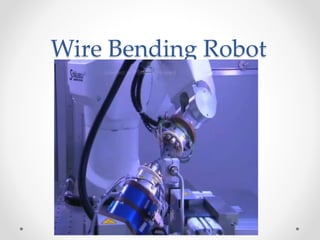

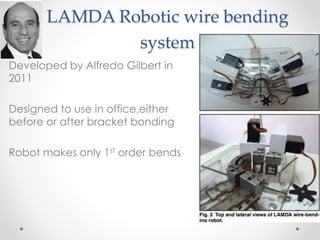

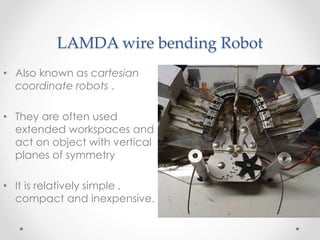

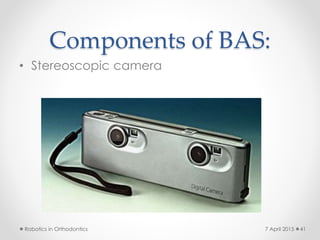

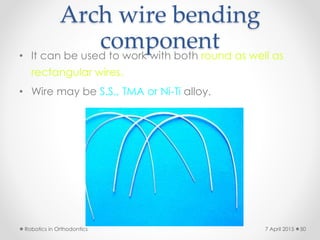

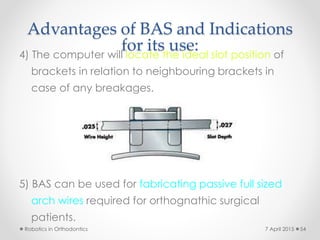

This document provides an overview of robotics applications in orthodontics. It discusses the history of robotics and various robots that have been developed for tasks like wire bending, appliance fabrication, and manufacturing of aligners. Wire bending robots can precisely bend archwires to customized specifications to improve treatment accuracy and efficiency. Robots are also used for digital fabrication of splints and may have future applications in areas like nano robots and research. Overall, robotics is allowing orthodontists to spend more time on diagnosis and planning rather than appliance production tasks.