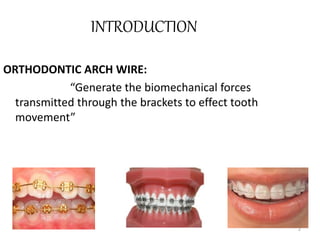

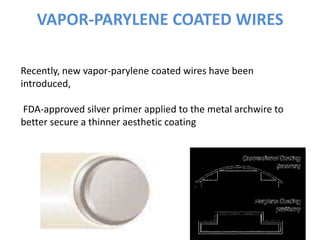

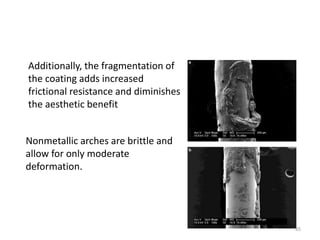

Dr. Zeba Siddiqui presented on various orthodontic archwire materials. Several archwire types were discussed including Optiflex, Bioforce, Super Cable, graded and formable nickel titanium wires. Optiflex is a clear aesthetic wire made of optical fibers. Bioforce applies varying force levels along the arch. Super Cable is a superelastic wire made of 7 strands. Graded and formable nickel titanium wires can be customized with different force levels and bends. Other wire types discussed include titanium niobium, timolium titanium, and coated or combined wires designed for aesthetics, force delivery or finishing.