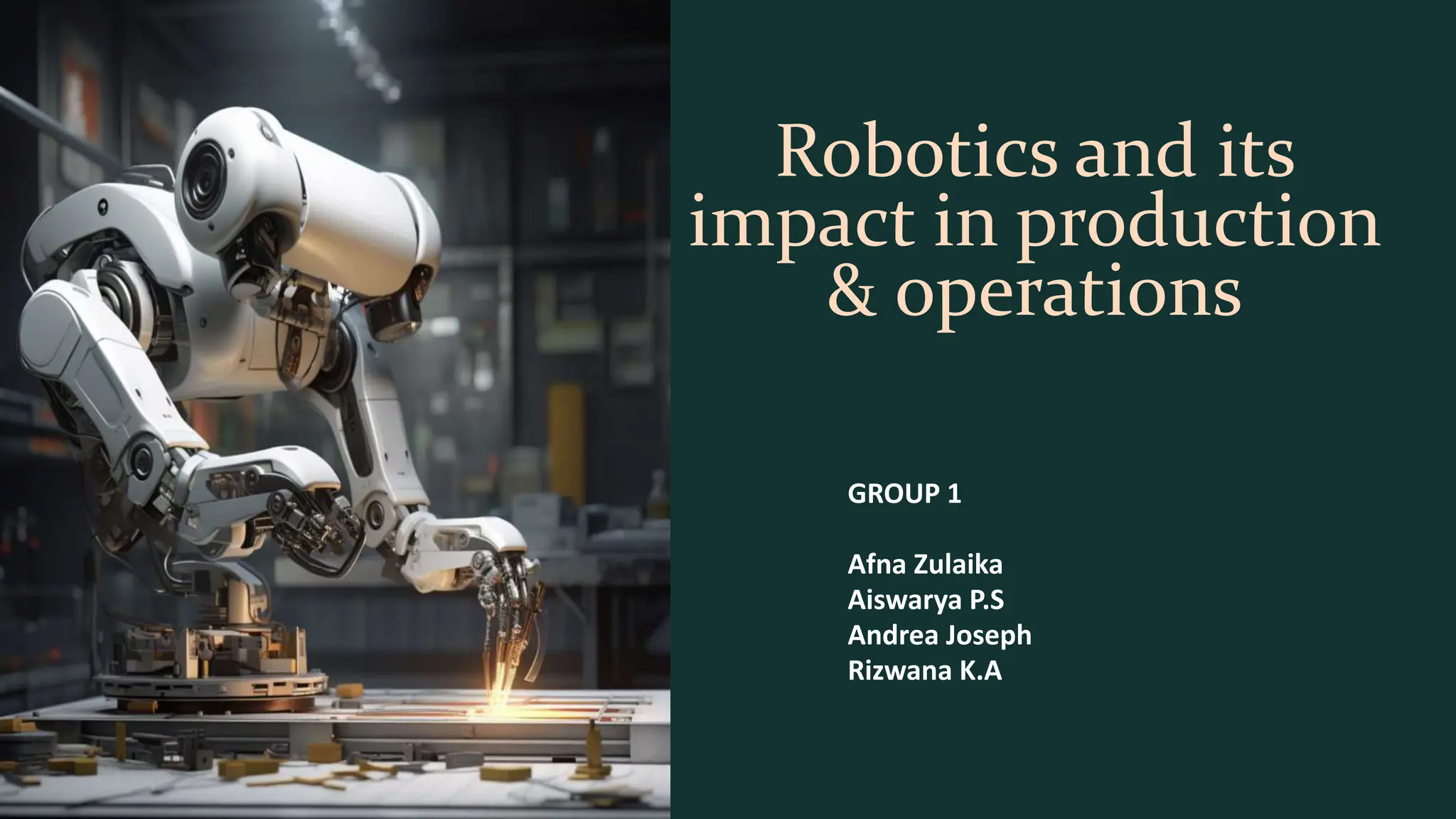

The document discusses the role of robotics in production and operations, highlighting various types of robots such as industrial robots, automated guided vehicles, collaborative robots, and drones, which enhance efficiency and safety in manufacturing. It also covers applications of robotics in logistics, including order picking and truck loading, as well as the benefits and challenges of integrating robotics into existing systems. Additionally, the future of robotics involves advanced automation, increased collaboration with humans, AI integration, and ethical considerations regarding job displacement and safety.