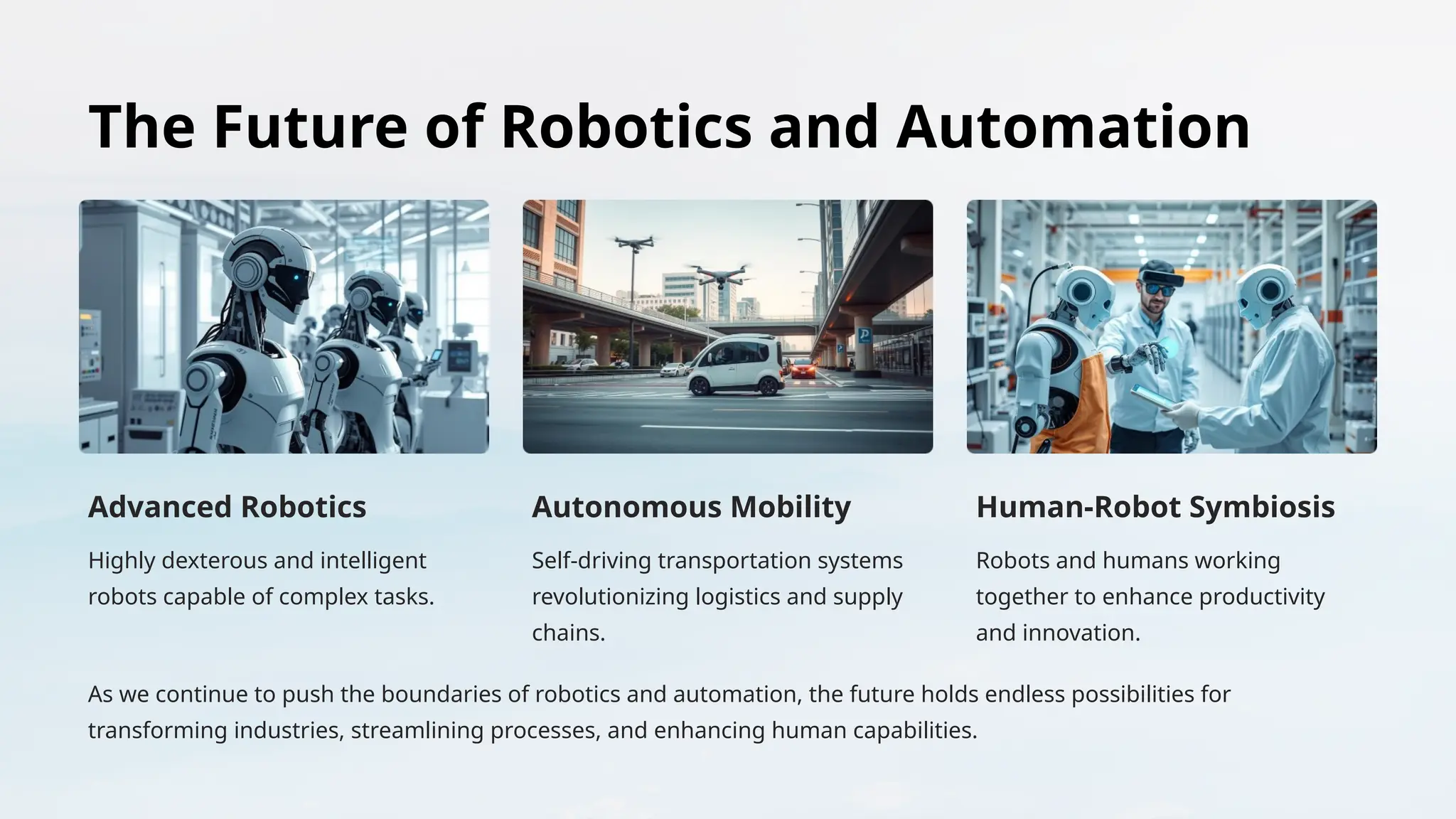

This presentation discusses current and future trends in robotics and automation, focusing on advancements shaping manufacturing and related fields. Key topics include Industry 4.0 technologies, collaborative robots, AI-driven processes, and the emergence of Industry 5.0, which emphasizes human-robot collaboration and sustainable manufacturing practices. The future of robotics is portrayed as a landscape of advanced autonomy and enhanced human capabilities in various industries.