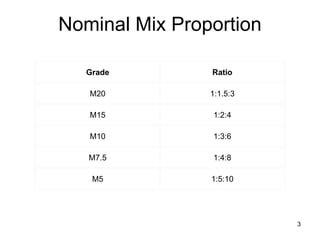

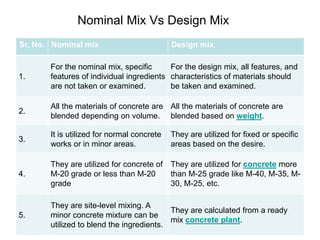

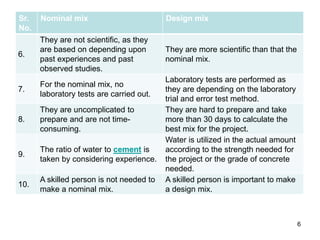

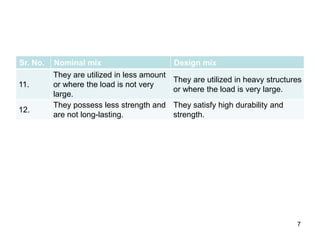

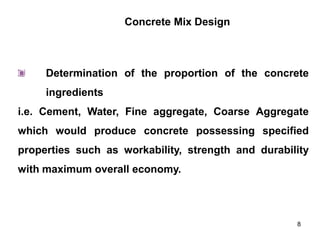

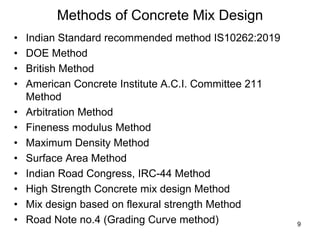

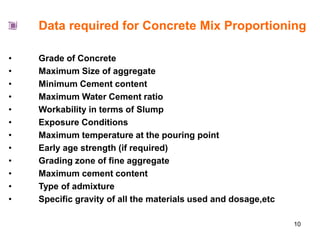

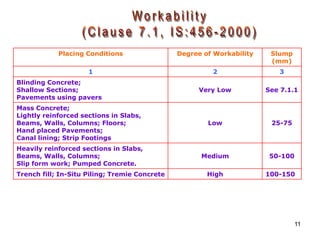

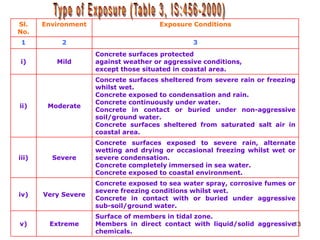

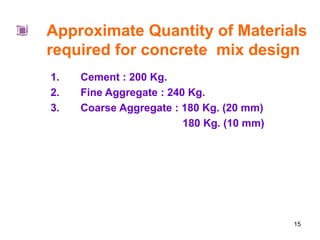

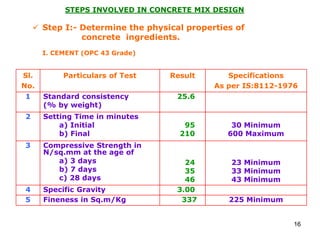

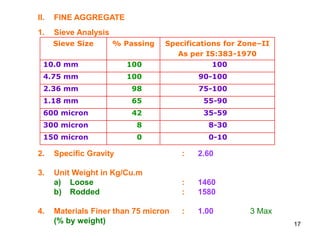

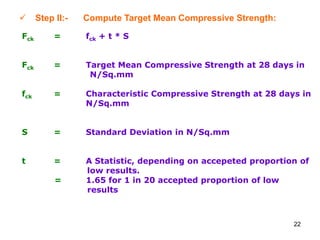

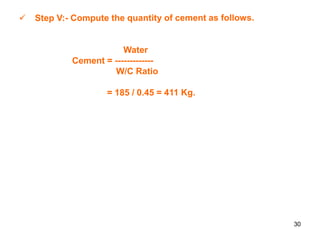

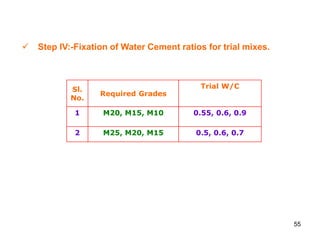

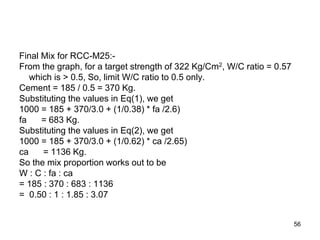

This document discusses concrete mix design and methods of mix design. It begins by explaining nominal mix and design mix concrete. Nominal mix uses fixed ingredient ratios while design mix calculates proportions to achieve needed strength. Several methods of concrete mix design are listed, including Indian standard, ACI, and IRC methods. Data required for mix proportioning is provided, such as grade, aggregate size, cement content, water-cement ratio, workability, and exposure conditions. Steps in concrete mix design involve determining material properties, selecting target strength, water-cement ratio, and volumes of ingredients to achieve the design mix. Trial mixes are made and tested to finalize the design mix.

![57

Specific Gravity of Cement [ IS : 4031 – 1988]:

Specific gravity of cement (Sc)

(W2 - W1)

= ---------------------------- x 0.79

(W4 - W1) - (W3 - W2)

Where,

W1 = Weight of specific gravity bottle in g

W2 = Weight of specific gravity bottle with about half filled cement in g

W3 = Weight of specific gravity bottle with about half filled cement

& rest is filled with kerosene in g.

W4 = Weight of specific gravity bottle completely filled with kerosene in g

0.79 = Specific Gravity of Kerosene.](https://image.slidesharecdn.com/cementconcretemixdesign-230524015508-9ebadd8d/85/CEMENT-CONCRETE-MIX-DESIGN-ppt-57-320.jpg)

![58

Specific Gravity of Fine Aggregate & Coarse Aggregate [ IS : 2386 (Part.3) -

1963]:

D

Specific gravity (Gs) = --------------

C – ( A – B)

Where,

A = Weight of Pycnometer vessel containing sample & filled with distilled water in g

B = Weight of Pycnometer completely filled with distilled water only in g

C = Weight of saturated surface dry sample in g

D = Weight of oven dried sample in g](https://image.slidesharecdn.com/cementconcretemixdesign-230524015508-9ebadd8d/85/CEMENT-CONCRETE-MIX-DESIGN-ppt-58-320.jpg)