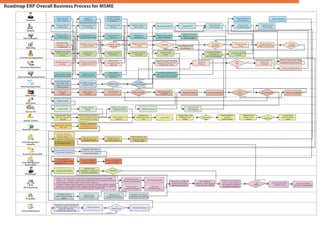

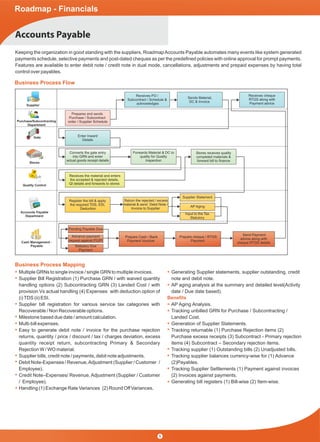

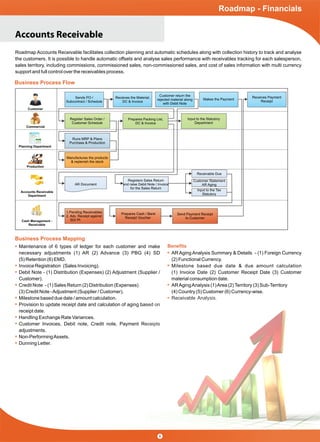

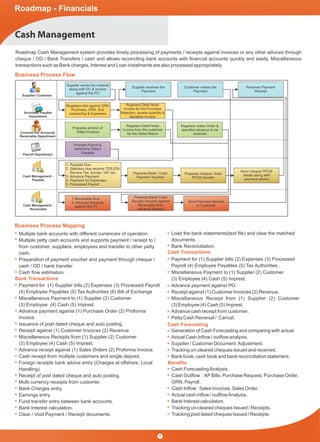

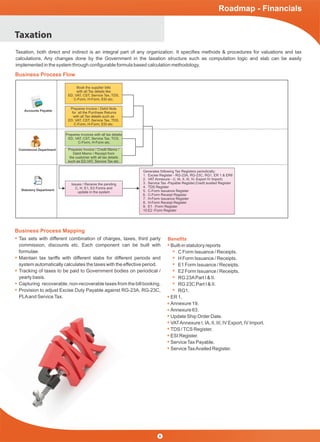

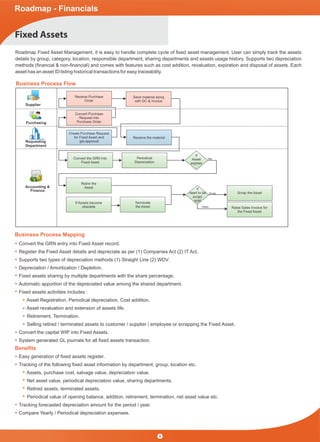

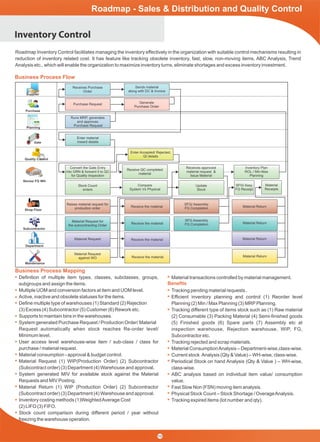

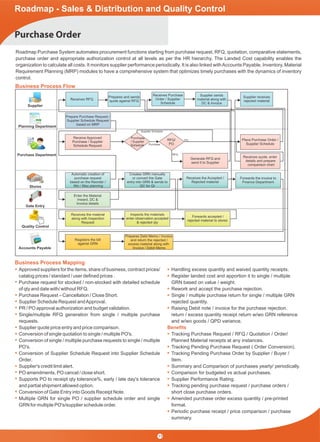

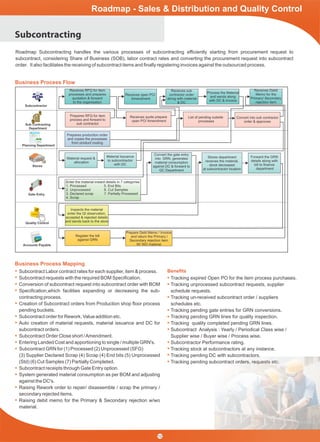

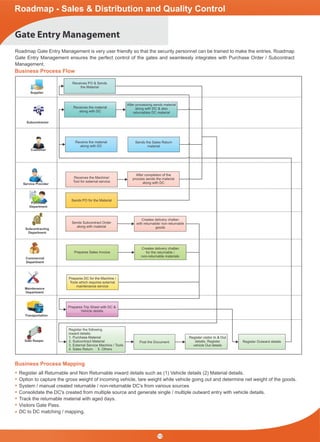

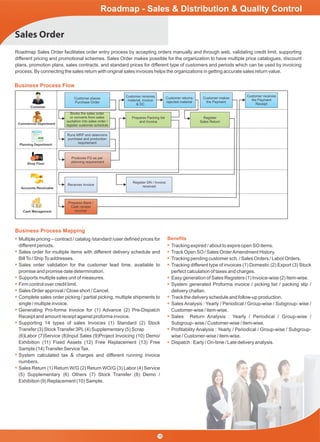

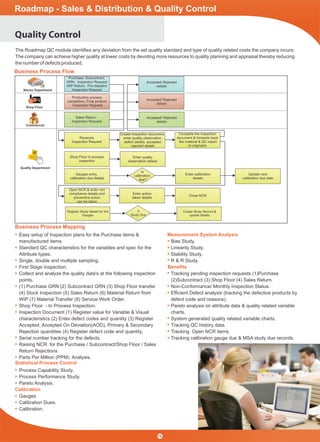

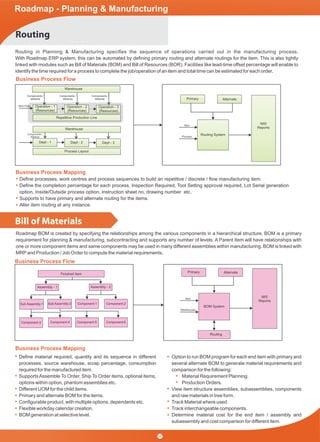

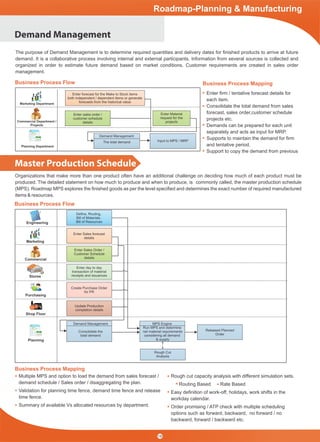

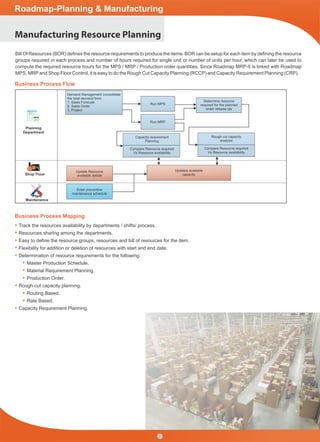

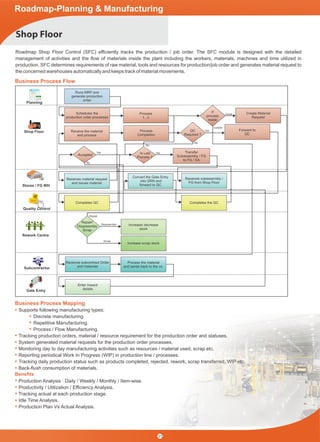

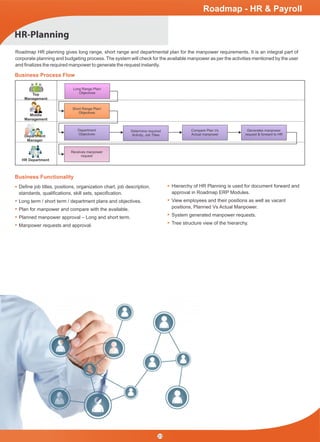

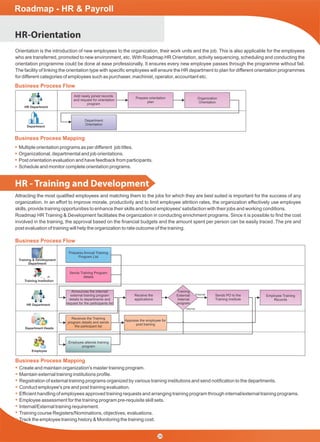

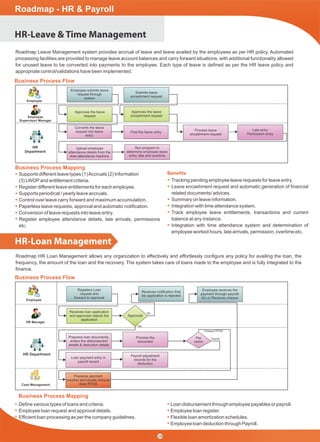

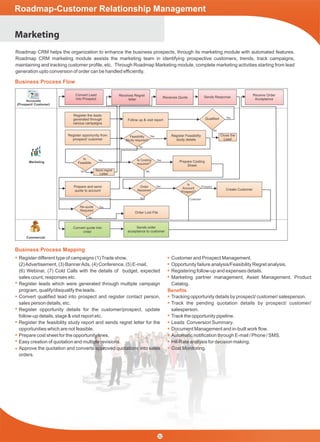

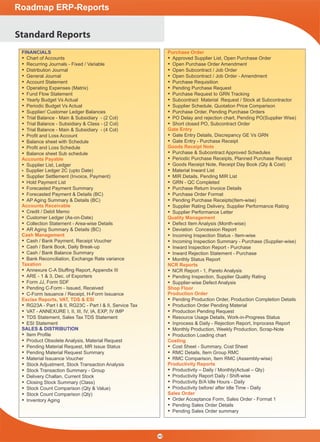

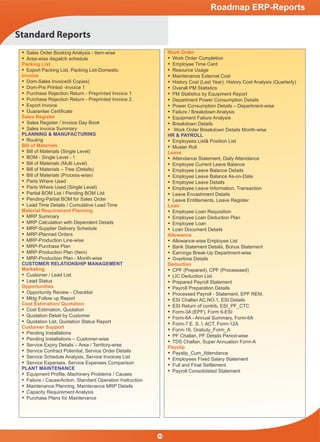

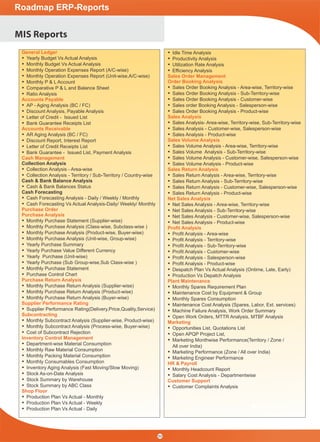

The document outlines the comprehensive functionalities and processes of the Roadmap ERP system, designed to manage various aspects of micro, small, and medium enterprises (MSMEs), including finance, HR, and supply chain management. It emphasizes the system's ability to streamline operations, improve decision-making, and adapt to changing market conditions while providing cost-effective solutions and user-friendly interfaces. Roadmap IT Solutions positions itself as a valuable partner for businesses seeking efficient enterprise resource planning through integrated approaches and industry-specific capabilities.