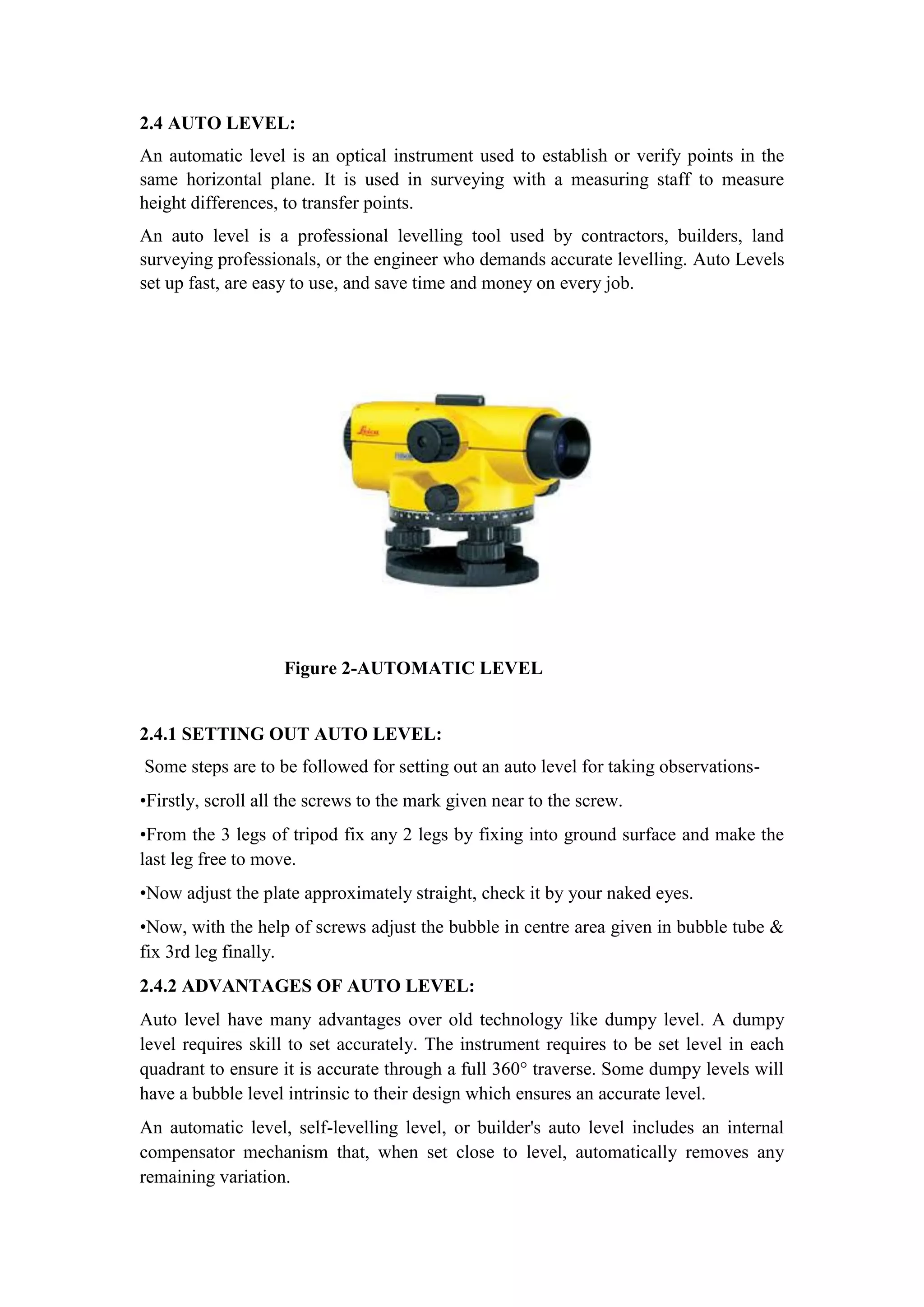

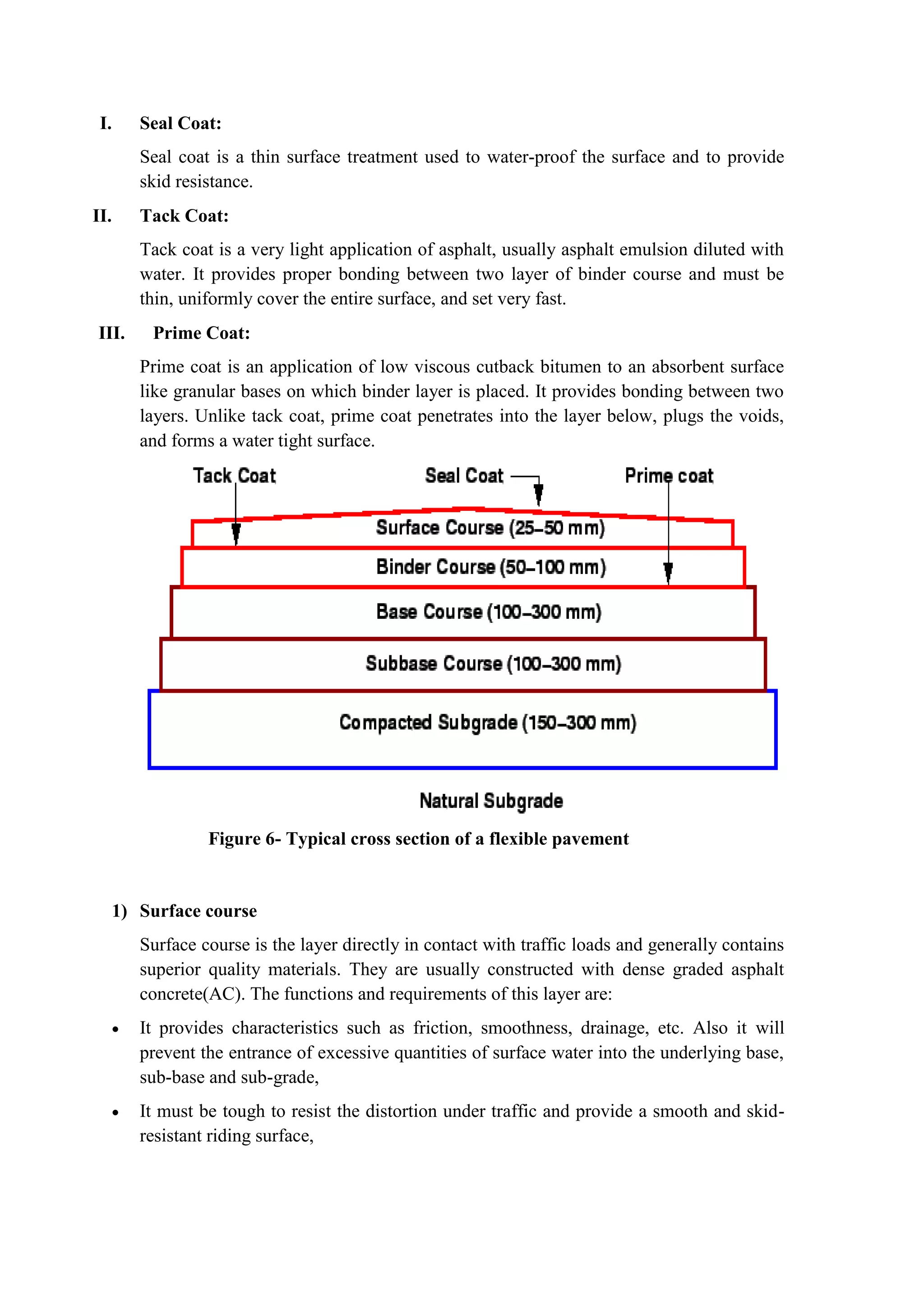

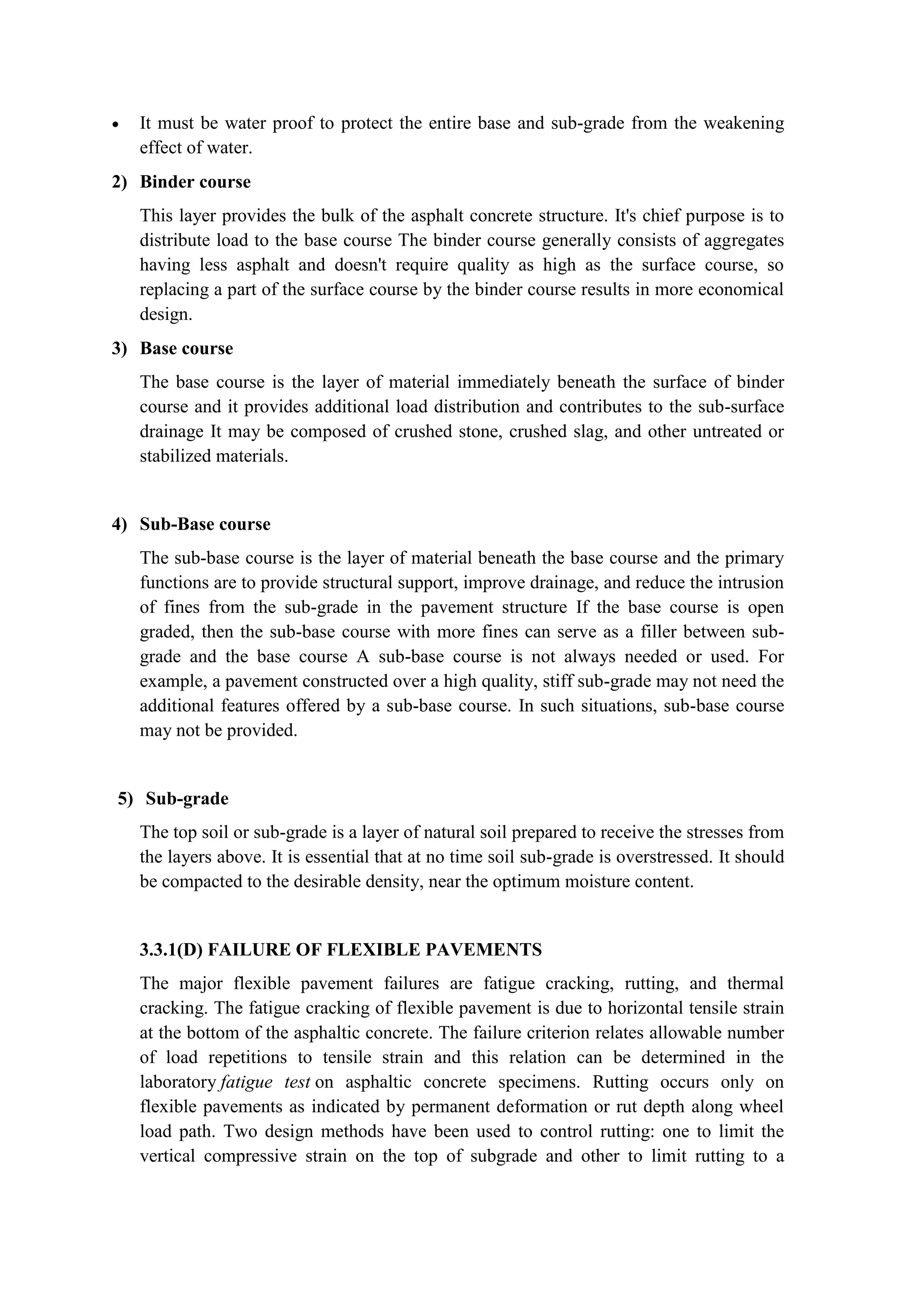

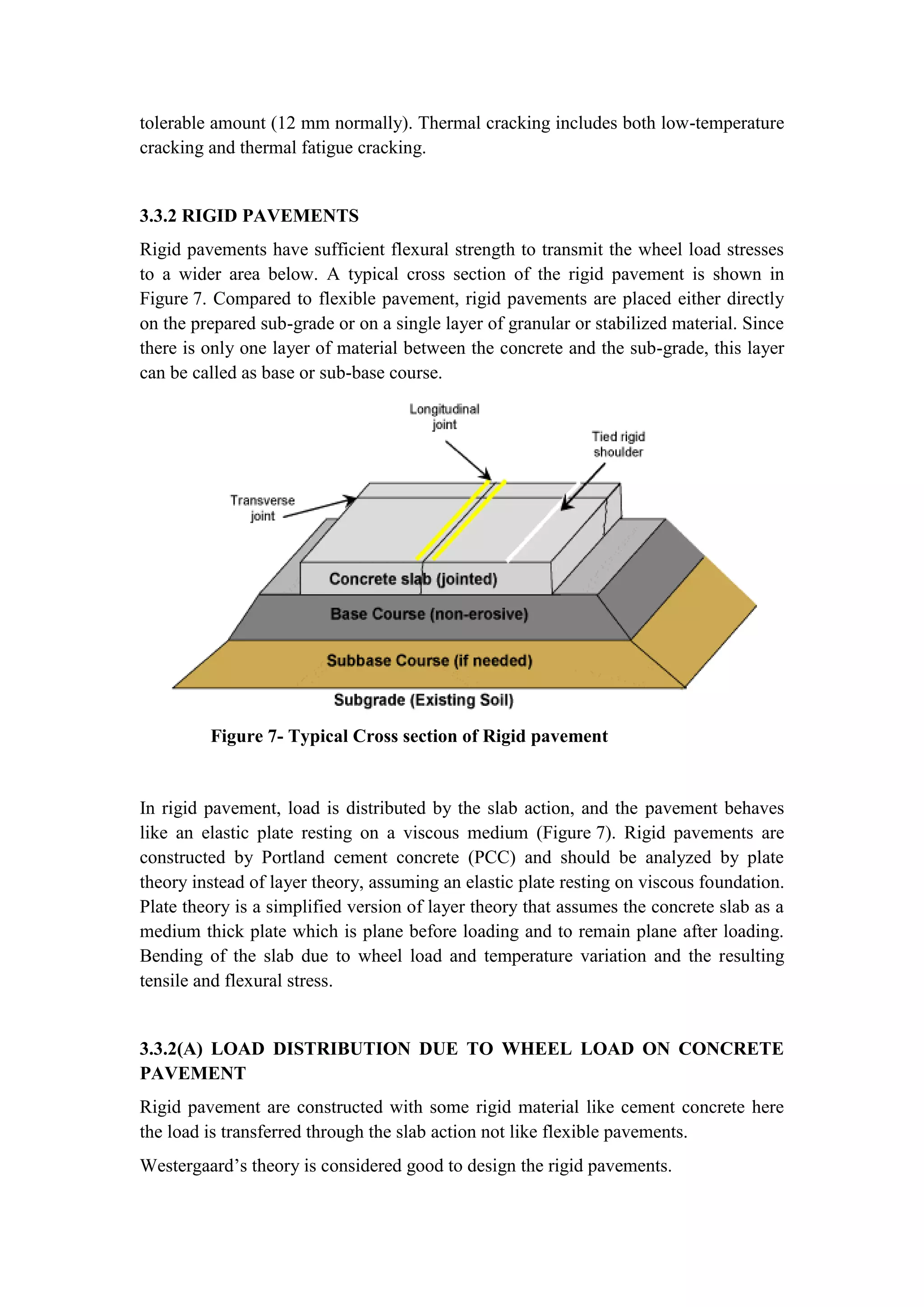

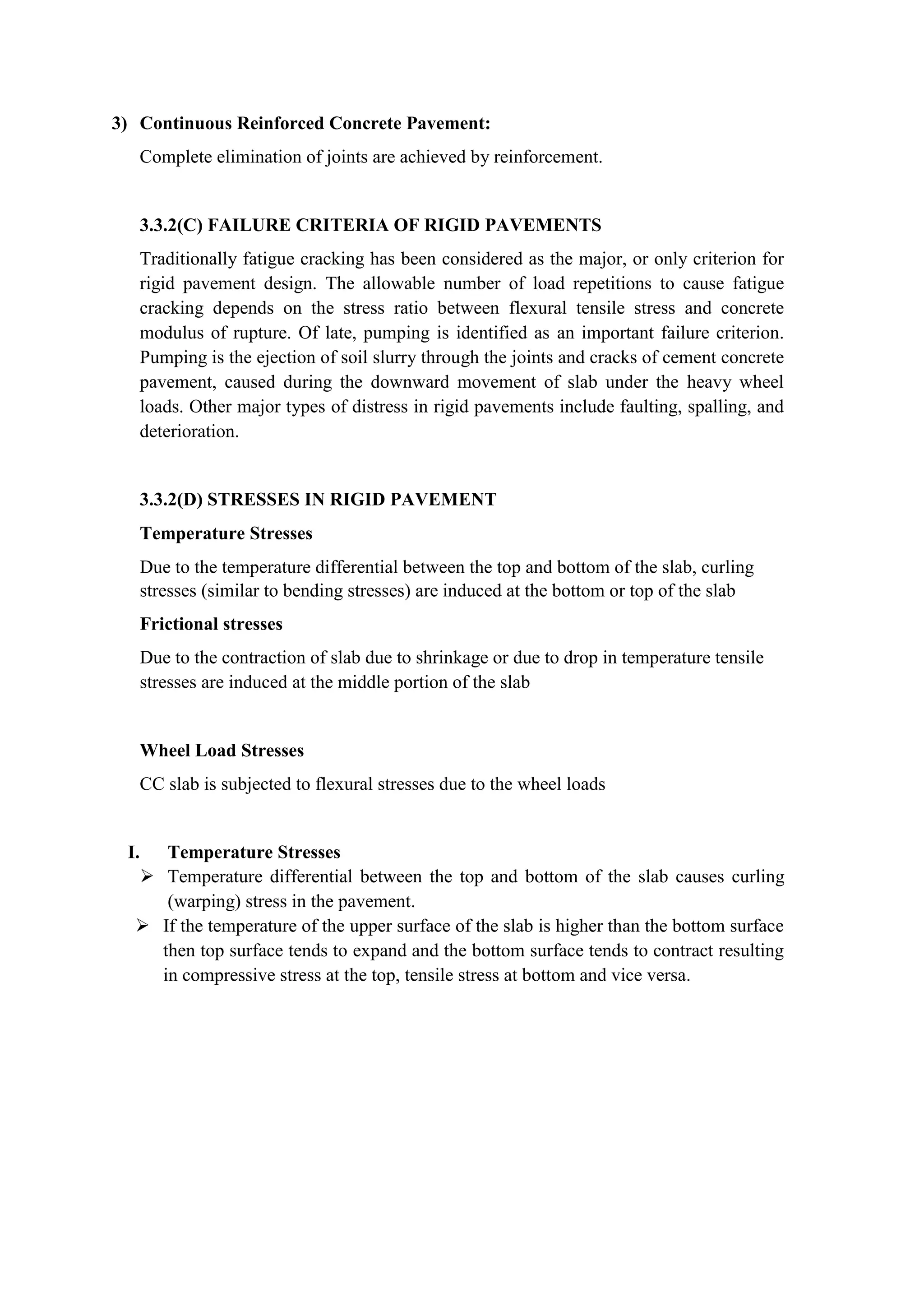

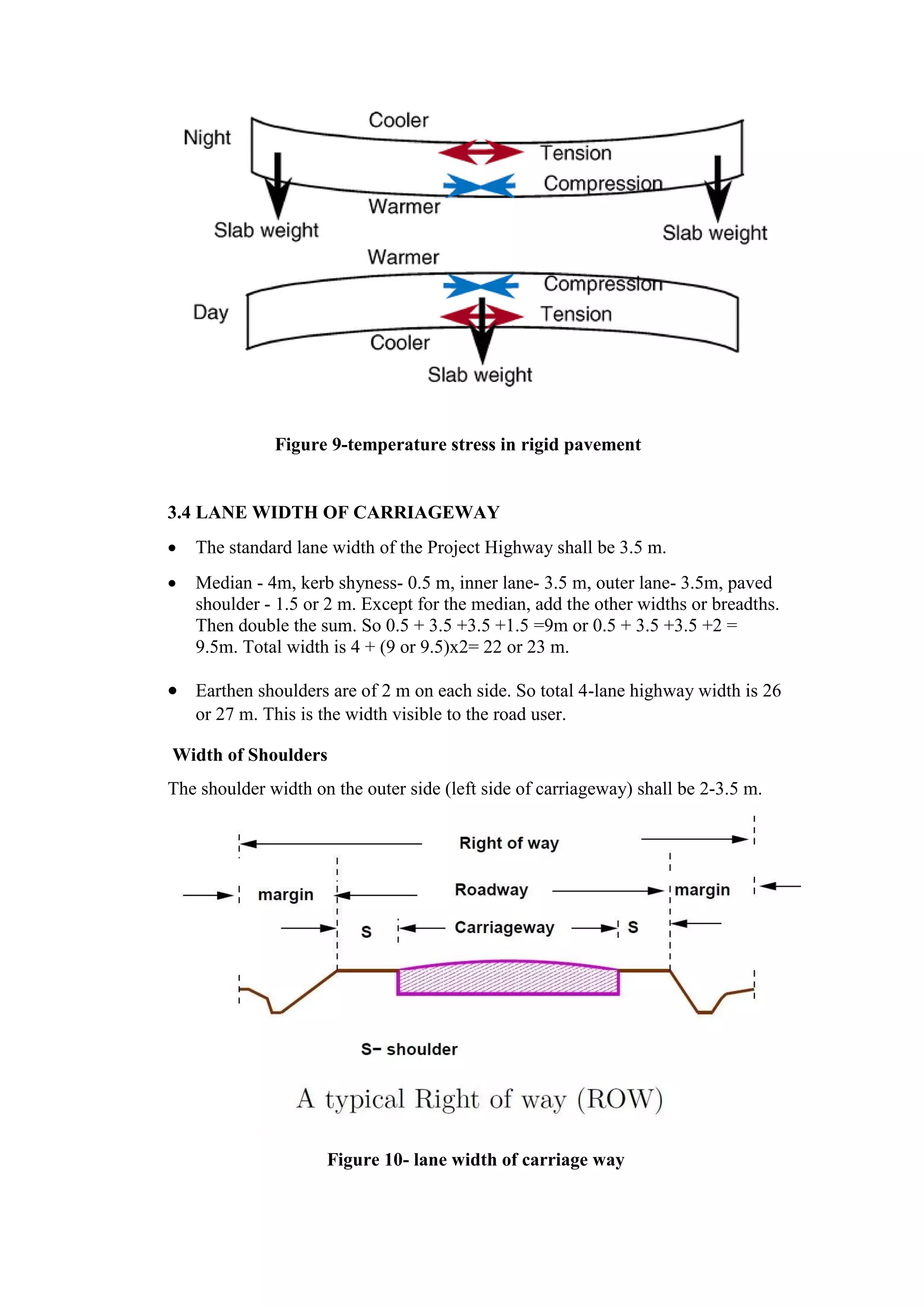

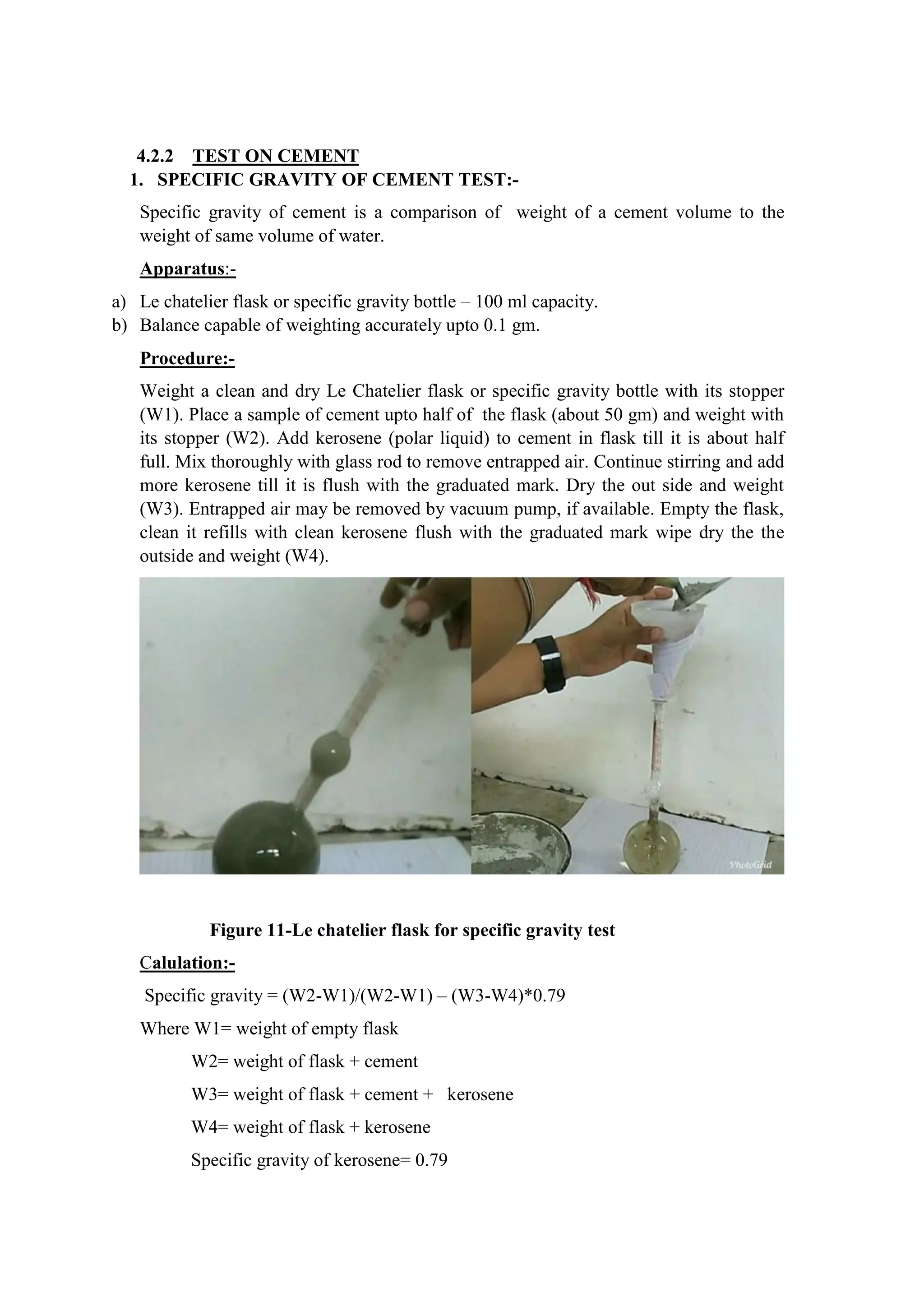

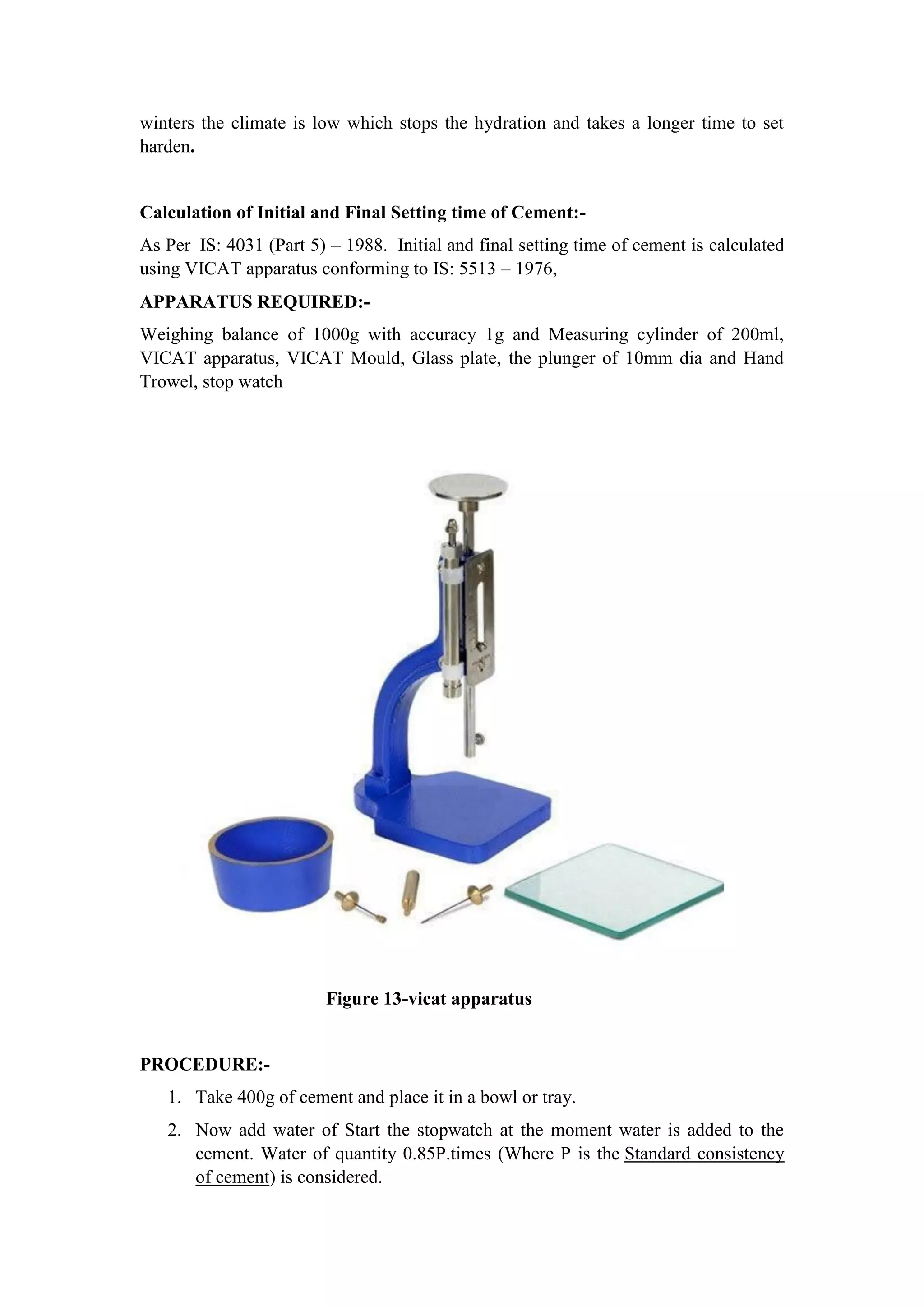

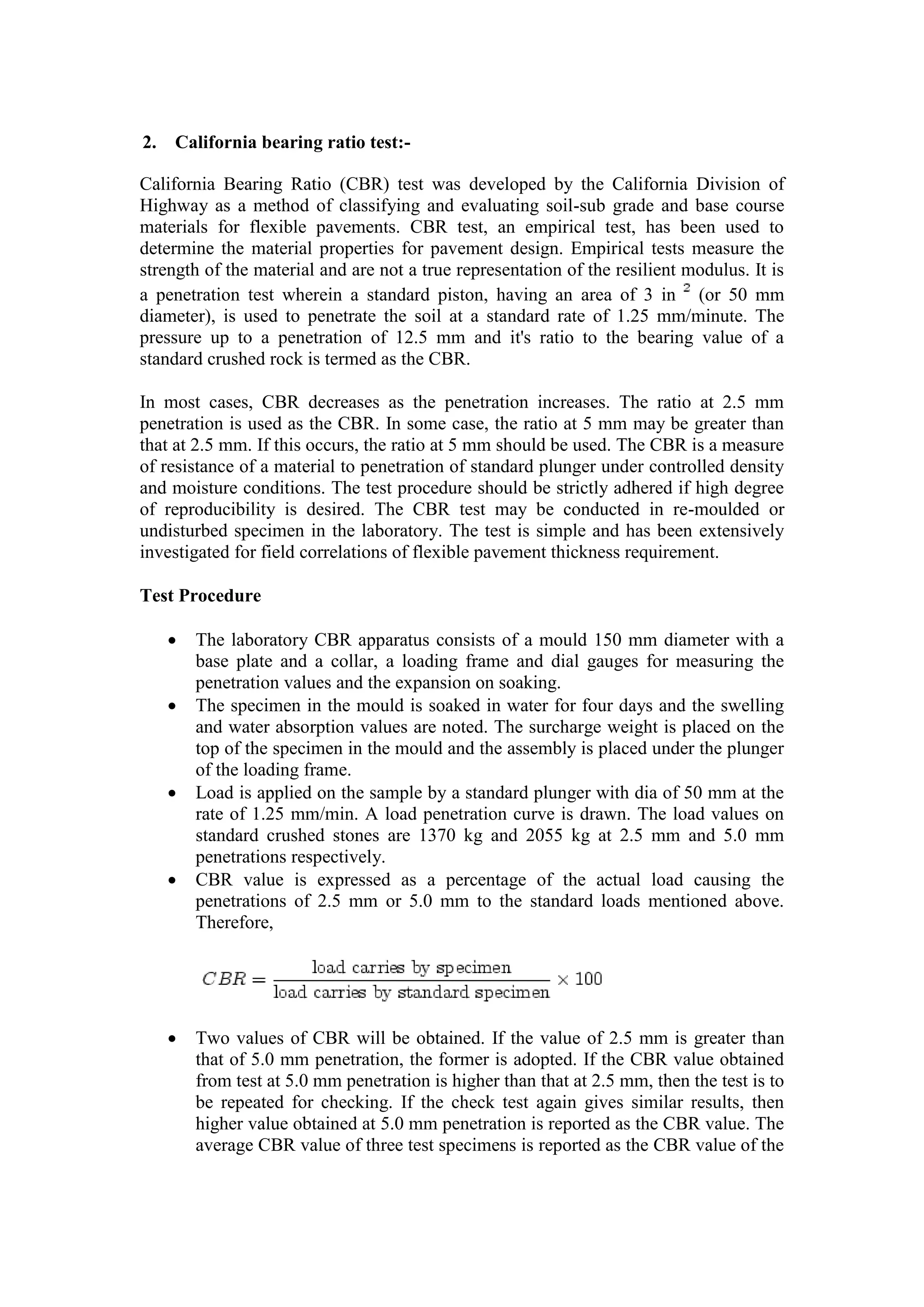

This document appears to be a report submitted by a student, Rakesh, on their practical training regarding the construction of a national highway. It includes sections on surveying, pavement design, minerals used in construction, subgrade preparation, concrete pavement, mixing and placing concrete, joints in rigid pavements, brooming and curing. The report was submitted in partial fulfillment of a Bachelor of Technology degree and aims to document Rakesh's training and experience overseeing the construction of rigid pavement on a national highway project.