The document outlines the national conference titled 'Trends & Challenges of Civil Engineering in Today’s Transforming World' organized by the Civil Engineering Department of S. N. Patel Institute of Technology & Research Centre on March 29, 2014. It emphasizes the role of civil engineering in socio-economic development and aims to address sustainability challenges in the field. The conference brings together academicians, students, and professionals to collaborate and discuss advancements and solutions in civil engineering.

![ISBN: 978-81-929339-0-0

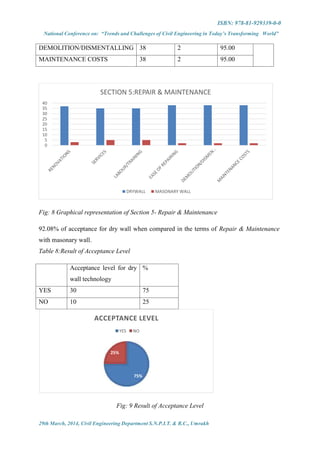

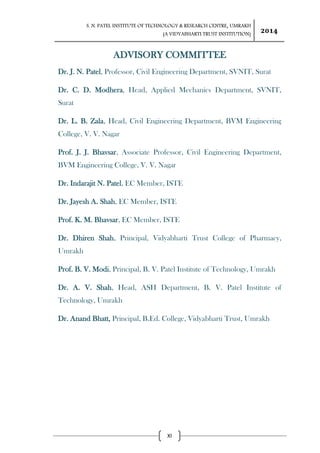

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Source: - www.efcoform.com, A.P.C. Herington

VII. CONCLUSION

With the invention of slip forming technique and due to speedier completion of work by

the technique, there are substantial savings in cost in terms of wages and interest. This

technique has no comprises against quality control and Homogeneity of structure.

The cost saving will not appear automatically just because slip forming has been used.

This technique has a lot of scope for improvement. But it can be adapted for tall structure.

Thus a slip form system involves:-

ACKNOWLEDGMENT

The Authors thankfully acknowledge to Dr. C. L. Patel, Chairman, Charutar Vidya Mandal,

Er.V.M.Patel, Hon.Jt. Secretary, Charutar Vidya Mandal, Mr. Yatinbhai Desai, Jay Maharaj

construction, Dr. F.S.Umrigar, Principal, B.V.M. Engineering College, Dr. L.B.Zala, Head

and Professor, Civil Engineering Department, Dr. A. K. Verma, Head and Professor,

Structural Engineering Department, B.V.M. Engineering College, Vallabh Vidyanagar,

Gujarat, India for their motivations and infrastructural support to carry out this research.

REFERENCES

[1] Anon. 1978. “Key to courthouse puzzle.” Eng. News-Rec., 20021, 26–27.

[2] Betterham R. G. 1980. Slip-form concrete, Longman, New York.

[3] Halpin D. W. and Riggs L. S. 1992. Planning and analysis of construction operations, Wiley, New York

[4] Hanna, A. S. 1998. Concrete formwork systems, Marcel Dekker, New York.

[5] Peurifoy R. L., and Oberlander G. D. 1996. Formwork for concrete structures, 3rd Ed., McGraw-Hill, New

York

[6] Pruitt R., Oberlander G. 2000. Concrete construction, 1st

Ed., McGraw-Hill, April, 32(4):345-349.

[7] www.Slipforminternational.com

[8] www.rexon.com

[9] www.neruformwork.com

[10]www.dokaformwork.com

[11]www.l&tskilledformingsystem.co.in](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-34-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

[12]www.masterbuilders.com

[13]www.google.co.in

[14]www.lagram.com

[15]www.Wikipedia.com](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-35-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

III. CASE STUDY:

Ribloc technology is used in many countries. In January 1994 Northridge earthquake severely

damaged the trunk sewer system of Santa Monica, USA. This resulted in one of this largest

sewer rehabilitation project in USA. Number of technologies including CIPP and Rib Loc

were tried. After the tremendous success of Ribloc in numerous projects, the city council of

Santa Monica decided award future projects to Ribloc on the basis of negotiations.

IV. CONCLUSIONS

Within a short span of 5 to 6 years, the awareness of Trenchless Technology in India is quite

significant. With conch progressive adoption of Trenchless technology in India, new

equipment and development of new materials will follow which will revolutionize the

construction industry and benefit the society. However, many planners, designers and

engineers are not yet accustomed to using them. Hence, there is a need for further

technological refinement , better information dissemination, and greater public awareness and

understanding regarding appropriate use of Trenchless technology and its contribution to

environmentally sustainable urban development. It is hoped that seminars on this newer

technology will be encouraged which will promote greater awareness in adoption of this new

technology for the development and management of the underground utilities.

ACKNOWLEDGMENT

The Authors thankfully acknowledge to Dr. C. L. Patel, Chairman, Charutar Vidya Mandal,

Er.V.M.Patel, Hon. Jt. Secretary, Charutar Vidya Mandal, Mr. Yatinbhai Desai, Jay Maharaj

construction, Dr. A. K. Verma, Head & Professor, Structural Engineering Department, Dr. B.

K. Shah, Associate Professor, Structural Engineering Department, B.V.M. Engineering

College, Vallabh Vidyanagar, Gujarat, India for their motivations and infrastructural support

to carry out this research.

REFERENCE

[1] Magazine of Civil engineering & construction review.

[2] Brig. D.K. Gunjal, (retd), consulting Engr, Banglore.

[3] T. Shivaraman, Chief Executive – Technology & D. Arivalagan, G.M –Technology, Shriram PPR

Technology Pvt. Ltd., Chennai.

[4] International seminar on “Underground Utility Infrastructure - Development and Management “ held

at Bangaloreaka, on February 10-11-2003, organized jointly by IndSTT, CIDC, BAI (Karnataka Centre) &

Karnataka state.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-42-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

ACKNOWLEDGMENT

The Authors thankfully acknowledge to Dr. C. L. Patel, Chairman, Charutar Vidya Mandal,

Er.V.M.Patel, Hon. Jt. Secretary, Charutar Vidya Mandal, Mr. Yatinbhai Desai, Jay Maharaj

construction, Dr. F.S.Umrigar, Principal, B.V.M. Engineering College, Dr. L.B.Zala, Head

and Professor, Civil Engineering Department, Dr. A. K. Verma, Head and Professor,

Structural Engineering Department, B.V.M. Engineering College, Vallabh Vidyanagar,

Gujarat, India for their motivations and infrastructural support to carry out this research.

REFERENCE

[1] Concrete Technology by M.S.Shetty

[2] Cement & Concrete Association of New Zealand Bulletin

[3] Cement Concrete & Aggregate Australia Bulletin

[4] www.concrete.net.au

[5] www.wikipedia.org

[6] www.google.co.in](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-52-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Horizontal casting of 100m3

slab using poker vibrator:

• Acceleration exposure 3.4m/s2

equaling a maximum exposure time of roughly 8

hours.

• No problem as the casting time was 7 hours and 46 minutes and 3-4 workers carried

the vibration load.

V. CONCLUSION

SCC with high workability, proper strength, and adequate durability can be produced

using locally available materials.

Attention must be paid to formwork, segregation, the air-void system, and shrinkage.

Self-Compacting Concrete is considered to be the most hopeful building material for

the expected innovative changes on the work site.

Alternative powders may be introduced without negative effect on concrete properties.

The reduction in number of un-healthy lifts is the most significant improvement to the

working environment from using SCC- The noise and vibration reduction is also nice.

ACKNOWLEDGMENT

The Authors thankfully acknowledge to Dr. C. L. Patel, Chairman, Charutar Vidya Mandal,

Er.V.M.Patel, Hon. Jt. Secretary, Charutar Vidya Mandal, Mr. Yatinbhai Desai, Jay Maharaj

construction, Dr. A. K. Verma, Head & Professor, Structural Engineering Department, Dr. B.

K. Shah, Associate Professor, Structural Engineering Department, B.V.M. Engineering

College, Vallabh Vidyanagar, Gujarat, India for their motivations and infrastructural support

to carry out this research.

REFERENCES

[1] Byen.wikipedia.org

[2] Hajime O. and Masahiro O. (2003) “Journal of Advanced Technology”

[3] M.S. SHETTY “Concrete Technology”, S. Chand and company ltd.

[4] www.google.com

[5] www.yotube.com

[6] www.wikipedia.com

[7] Seminasprojects.com/s/SCC-ppt](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-63-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

CONCLUSIONS

The following are the conclusion drawn from the study of Laser screed technology.Laser

Screeding consistently outperforms hand Screeding for precision and speed of flooring and

paving. Lower costs, reduced manpower, increased mobility and greater accuracy guarantee

the skilled teams will be 'on' and 'off' site with exceptional efficiency - allowing early access

for following trade and delivering improved customer satisfaction.The laser screed machines

have screed heads up to 3.6 m wide and the engine and hydraulic drive system, located in the

lower frame, significantly reduces noise and improves ease of maintenance.Moreover,

Simplified controls and an ergonomic design make the machines easy to operate, while a low

head height improves access in restricted areas.

ACKNOWLEDGEMENT

The Authors thankfully acknowledge to Dr. C. L. Patel, Chairman, Charutar Vidya Mandal,

Er.V.M.Patel, Hon. Jt. Secretary, Charutar Vidya Mandal, Mr. Yatinbhai Desai, Jay Maharaj

construction, Dr. F.S.Umrigar, Principal, B.V.M. Engineering College, Dr. L. B. Zala, Head

and Professor, Civil Engineering Department, Dr. A. K. Verma, Head and Professor,

Structural Engineering Department, B.V.M. Engineering College, Vallabh Vidyanagar,

Gujarat, India for their motivations and infrastructural support to carry out this research.

REFERENCES

[1] en.wikipedia.org

[2] GLENN A. SHEPHARD, 'LASER TECHNOLOGIES APPLICATION TO CONSTRUCTION'A Report

Presented to the Graduate Committee of the Department Civil Engineering in Partial Fulfillment of the

Requirements for the Degree of Master of Civil Engineering, University of Florida,Summer 1999

[3] pmallam.dns-systems.net

[4] Ravindra K Dhir, Peter C. Hewlett “Concrete in the Service of Mankind: Radical concrete technology,

Volume 4” E & FN SPON Publication, pp-535.

[5] techniconconstruction.com

[6] www.amanabuildings.com

[7] www.aquariustech.net

[8] www.cogriasia.com

[9] www.engineeringnews.co.za

[10]www.somero.com](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-73-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

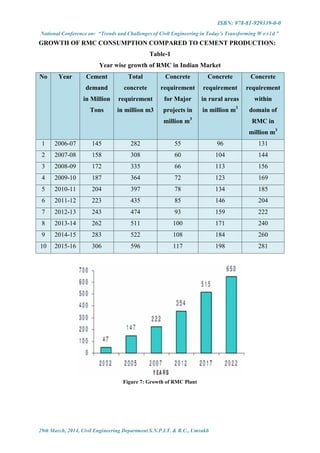

CONCLUSIONS

Ready Mix Concrete is a modern technique of production of concrete in massive quantities

away from the actual site of placing. It is very useful where demand of concrete is very high

and construction sites are in congested areas, where mixing on site is not possible due to lake

of storage place. RMC is ready to use material. It is widely adopted throughout the world. It

gives higher strength to the structure and it also provides higher Durability to the structure. It

reduces noise pollution as well as air pollution.The Supervisory and labour costs associated

with the production of RMC is less, and the quality of concrete is high. It is suitable for huge

industrial and residential projects where time plays a vital role.So ultimately it provides

economy in the construction and better finish to the structure. Hence the advantages of RMC

are realized by engineers and contractors in the construction industry.

ACKNOWLEDGMENT

The Authors thankfully acknowledge to Dr. C. L. Patel, Chairman, Charutar Vidya Mandal,

Er.V.M.Patel, Hon.Jt. Secretary, Charutar Vidya Mandal, Mr. Yatinbhai Desai, Jay Maharaj

construction, Dr. F. S. Umrigar, Principal, B.V.M. Engineering College, Dr. L. B. Zala, Head

and Professor, Civil Engineering Department, Dr. A. K. Verma, Head and Professor,

Structural Engineering Department, B.V.M. Engineering College, Vallabh Vidyanagar,

Gujarat, India for their motivations and infrastructural support to carry out this research.

REFERENCE

[1] “Concrete Batch Plant Modeling Guide”. Iowa Department of Natural Resources. Retrieved 3 October

2012.

[2] "Introduction of Concrete Mixing Plant". CONCRETE-MIXINGPLANT.COM.

[3] IS 4926:2003, “The Indian Standard Specification”

[4] www.janeoocn.com

[5] www.wekepedia.com

[6] www.google.com

[7] http://www.cashconcrete.com/about-us/

[8] R. S. Aggrawal , “Concrete Technology” Published by S. Chand

[9] http://www.rmcc.com/concrete-education-ready-mix-concrete.html

[10]http://www.boralcolorado.com/bcm-about-us

[11]http://www.grecoreadymix.com/ready/applications.html](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-83-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

REFERENCES

[1] Conditions and Constraints in the Formwork Systems for Complex High-rise Building – with cases

from Hong Kong

[2] Moladiformwork.com

[3] Masterbuilder.co.in

[4] Novaformworksystem.com

[5] Sisconformwork.com

[6] Theconstrucor.org

[7] www.desireindia.in

[8] www.asiaric.com/aboutus.html](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-93-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

(e) It avoids traffic jams.

(f) It makes the use of the line(track) of the old pipe possible.

(g) It saves underground space (pipe busting).

(h) It reduces the impact on the environment.

(i) It provides the hassle-free road surface.

(j) It is possible to lay service lines across the railway track, narrow lanes etc. When open

trenching is impossible.

VI. CONCLUSIONS

The Sewer Rehabilitation System provides a variety of benefits to the user. It combines

proven sewer lining technologies, state of the art materials and the advantage to retain

valuable size of sewer lines in ever-growing cities, a fact which is yet underestimated by the

majority of users.The time will soon come when the conventional method of open trench

digging will be selectively banned in India. To begin with, work should be undertaken for

crossings under roads, national highways, railways, canals etc. and all renovations of

sewerage systems in metropolitan cities. Enough know-how and technology are available to

make a beginning in the field.

ACKNOWLEDGMENT

The Authors thankfully acknowledge to Dr. C. L. Patel, Chairman, Charutar Vidya Mandal,

Er.V.M.Patel, Hon.Jt. Secretary, Charutar Vidya Mandal, Mr. Yatinbhai Desai, Jay Maharaj

construction, Dr. F.S.Umrigar, Principal, B.V.M. Engineering College, Dr. L.B.Zala, Head

and Professor, Civil Engineering Department, Dr. A. K. Verma, Head and Professor,

Structural Engineering Department, B.V.M. Engineering College, Vallabh Vidyanagar,

Gujarat, India for their motivations and infrastructural support to carry out this research.

REFERENCES

[1] Jagadish Chandra, “Trenchless Technology in India: Need of the New Millennium.” Civil Engineering and

Construction Review October 2000- page 48

[2] Maninder Singh, “Techniques of Trenchless Technology In Use In India.” Civil Engineering and

Construction Review October 200- page 43

[3] NeerajauganiSethi, “Pre- Requisites for Trenchless Technology.” Civil Engineering and Construction

Review October 2000- page 2](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-104-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

[4] Sarkar A.K, “Trenchless Technology and INDSTT In India.” Civil Engineering and Construction Review

October 2000- page 13

[5] The Construction Journal of India November 2001- page21

[6] www.istt.com

[7] www.nodig.com

[8] www.piperehab.org

[9] www.nodigengineering.com

[10]www.ttmag.com

[11]www.directionaldrilling.com

[12]www.rehabshowcase.com

[13]www.rehabroadshow.com](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-105-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

REFERENCES

[1] Building Construction by B.C. Punmia, Ashok Kumar Jain, Arun Kumar Jain, Luxmi Publication (P) LTD

[2] Lesson 7: Construction Dewatering and Ground Freezing, Temporary Structures, Winter Quarter 2007,

Professor Kamran M. Nemati, Department of Construction Management, University of Washington

[3] http://civil-engg-world.blogspot.in/2008/12/electrical-stabilization-of-soil.html

[4] http://www.fhwa.dot.gov/bridge/tunnel/pubs/nhi09010/12.cfm

[5] http://www.haywardbaker.com/WhatWeDo/Techniques/Grouting/ChemicalGrouting/default.aspx

[6] http://www.ecopolychem.com/home/

[7] http://www.aquatechdewatering.com/gallery.php

[8] www.weirminerals.compdfBrochure%20dewatering%20systems.pdf

[9] www.google.com](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-114-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

REFERENCE

[1] R.P.Rethaliya Books on “Concrete Technology”

[2] R.Santhakumaran, Books on “Concrete Technology”

[3] www.construction world.com

[4] www.construction chemicals.com

[5] www.chemical.gov.in

[6] Water reducing concrete admixture” Published in IS: 9103 ASTM C: 494

[7] Waterproofing Concrete and Mortar Admixture Published in IS: 2645 – 1975](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-129-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

VallabhVidyanagar, Gujarat, India for their motivations and infrastructural support to carry

out this research.

REFERENCE

[1] Bryan Kang, Mary Wang, Xia Xiao, Madeline Ziser, Amending the current levee breach response

protocol in the California delta.

[2] Frank Bacik, Aqua Dam: Another Scotia Success Story, The Scotia independent,april29, 2011,

VOLUME I, ISSUE II

[3] www.aquadam.net/RefMaterials/refmaterials.html

[4] www.welltech.com.au/dewatering/dwPortBunds.html

[5] www.hydrologicalsolutions.com/aqua-barrier

[6] www.water-dam.co.uk/

[7] www.aquadam.net/

[8] www.damitdams.com/](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-138-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

In support scaffolds, double layered scaffold is costly compared to the single layered

scaffold. While double layered scaffold can be used for several stories or large-scale

construction works.

In recent trends, metal scaffolds are widely used to compare to bamboo scaffolds due

to its durability and safety.

Various special scaffolding is beneficial for reducing accidents on large construction

sites. For safety and health point of view, standard codes should be preferred for

minimizing hazards.

So, various scaffoldings are very helpful, for small as well as large construction

projects which should be selected by considering financial level of project.

ACKNOWLEDGMENT

The Authors thankfully acknowledge to Dr. C. L. Patel, Chairman, Charutar Vidya Mandal,

Er.V.M.Patel, Hon.Jt. Secretary, Charutar Vidya Mandal, Mr. Yatinbhai Desai, Jay Maharaj

construction, Dr. F.S.Umrigar, Principal, B.V.M. Engineering College, Dr. L.B.Zala, Head

and Professor, Civil Engineering Department, Dr. A. K. Verma, Head and Professor,

Structural Engineering Department, B.V.M. Engineering College, Vallabh Vidyanagar,

Gujarat, India for their motivations and infrastructural support to carry out this research.

REFERENCES

[1] Building Construction by Dr. B. C. Punamia

[2] Dominic Mak Hung-kae Legislative Control Regime for Ensuring Safe Use of Scaffolding, Symposium on

Bamboo and Metal Scaffolding 1998.

[3] Francis K.W. Wong, Bamboo Scaffolding-Safety Management for the Building Industry in Hong Kong,

April 1998,Hong Kong Polytechnic University

[4] Wong Che Keung, Identification of the Key Factors Involved in Bamboo-scaffolding-Related Accidents on

Construction Sites in Hong Kong A report submitted as partial fulfillment of the requirements for master of

applied science (safety management) 1998.

[5] http://www.wti-scaffold.com/2010/05/24/the-benefit-of-suspended-scaffolding

[6] www.osho.com/scaffoldingtypes

[7] www.wikipedia.com/scaffolding

[8] www.scaffoldindia.com

[9] www.scaffoldscaffolding.com](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-151-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Head & Professor, Structural Engineering Department, Dr.B.K.Shah, Associate Professor,

Structural Engineering Department, B.V.M. Engineering College, Vallabh Vidyanagar,

Gujarat, India for their motivations and infrastructural support to carry out this research.

REFERENCE

[1] Centre for Advancement of Trenchless Technologies (CATT), University of Waterloo, Ontario, Canada

(Link: www.civil.uwaterloo.ca/catt).

[2] Indian Society for Trenchless Technology (IndSTT), (Link: http://www.indstt.org).

[3] IETC Urban Environment Series, “Trenchless Technology Systems: An Environmentally Sound

Technology for the Installation, Maintenance and Repair of Underground Utility Services”, UNEP-DTIE-

IETC/ISTT.

[4] International Society for Trenchless Technology (ISTT), London, UK,

(Link: www.istt.com).

[5] Jagadish Chandra, “Trenchless Technology in India: Need of the new millennium.” Civil Engineering and

Construction Review October 2000- page 48.

[6] Maninder Singh, “Techniques of Trenchless Technology in Use in India.” Civil Engineering and

Construction Review October 2004- page 43.

[7] Neeraja Lugani Sethi, “Pre- Requisites for Trenchless Technology”, Civil Engineering and Construction

Review October 2000- page 21.

[8] Najaf, Mohammad. 2005. Trenchless Technology, McGraw-Hill Professional.

[9] Sarkar A.K, “Trenchless Technology and INDSTT in India.” Civil Engineering and Construction Review

October 2000- page 13.

[10]Steve Orchad, “Directional Drilling and Associated Technologies”, No-Dig International Journal,

November 2008.

[11]United States Department of Agriculture Forest Service Technology & Development Program , “Summary

of Trenchless Technology for Use With USDA Forest Service Culverts”, 7700–Transportation

Management September 2005 0577 1201—SDTDC.

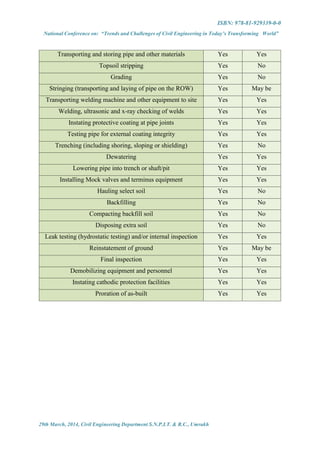

Table: 1

Open Cut Excavation V/S Trenchless Technology

Construction Operations Open Cut

Excavation

Trenchless

Technology

Route surveying Yes Yes

Lard and easement acquisitions Yes Yes

Mobilizing Equipment and Personnel Yes Yes

Preparing the right-of-way (ROW) (cleaning and grubbing) Yes May be](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-164-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

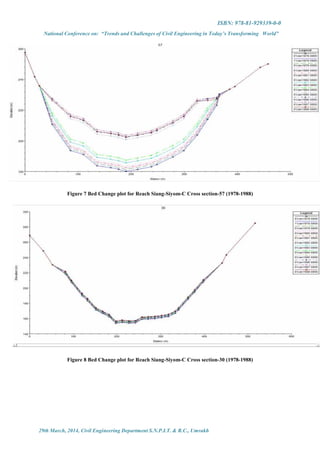

Fig. 10 and Fig. 11 shows comparison of idealized section with surveyed sections in the

present study reach which indicates very good agreement in the upper portion, indicating

stability, but poor agreement in the enlarged cutoff reach downstream, which indicates that

this lower enlarged reach will be aggrading over time.

ACKNOWLEDGMENT

The authors are thankful to Mr. B. M. Vadher, Principal, Dr. S. & S. S. Ghandhy Government

Engineering College, Surat and Director, Sardar Vallabhbhai Institute of Technology for their

motivational & infrastructural supports to carry out this research.

REFERENCES

[1] Agnihotri P. G and Patel J. N. 2011. Modification of channel of Surat city over Tapi river using HEC- RAS

software. International Journal of Advanced Engineering Technology. Vol. 2, pp. 231-238.

[2] Anthony L. Firenzi, Chester C. Watson, and Brian P. Bledsoe. 2000. Stable Channel Design for Mobile

Gravel Bed Rivers, Journal of Water Resource and Protection. Vol. 10, pp. 1-9.

[3] Timbadiya P. V., Patel P L., Porey P. D.2001,Calibration of HEC-RAS model on Prediction of Flood for

lower Tapi river India, Journal of Water Resource and Protection. Vol. 3, pp. 805-811

[4] Garde R. J, Raju Ranga K. G. 2000. Mechanics of Sediment Transportation and alluvial stream’s problems,

New Age International publishers (P) Ltd., New Delhi, India.

[5] IL Hong, Joongu Kang, Hongkoo Yeo, Yonguk Ryu.2011. Channel Response Prediction for Abandoned

Channel Restoration and Applicability Analysis, Journal of Engineering, Vol. 3, pp. 461-469.

[6] John Shelly and Parr David A.2009.Hydraulic design functions for Geomorphic channel design and analysis

using HEC-RAS, Journal of World Environmental and Water Resources Congress. Vol. 2, pp. 41-50.

[7] Neary Vincent S. Neary and Nic Korte.2001. Preliminary channel design of Blue River reach enhancement

in Kansas City, American society of Civil Engineering. Vol. 1, pp. 31-42.

[8] www.google.com

Figure 10: Comparison of computed water level using 2006

discharge and level of bank

0

2

4

6

8

10

12

14

CS-1

CS-6

CS-11

CS-16

CS-21

CS-26

CS-31

CS-36

CS-41

CS-46

Existing Levels

Computed R.L

0

2

4

6

8

10

12

14

CS-1

CS-6

CS-11

CS-16

CS-21

CS-26

CS-31

CS-36

CS-41

CS-46

Existing Levels

Computed R.L

0

2

4

6

8

10

12

14

CS-1

CS-6

CS-11

CS-16

CS-21

CS-26

CS-31

CS-36

CS-41

CS-46

Existing Levels

Computed R.L

Figure 11: Comparison of computed water level using 1944

discharge and bank level

0

2

4

6

8

10

12

14

CS-1

CS-4

CS-7

CS-10

CS-13

CS-16

CS-19

CS-22

EXISTING R.L

COMPUTED R.L](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-173-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

[9] www.wikipedia.com

[10] www.suratmunicipal.gov.in](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-174-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

XI.CASE STUDIES OF INTELLIGENT BUILDING

A. Case Study – 1 [Forum Mall, Bengaluru]

[a]

[b]

Figure 3: Forum Mall, Bangalore

Source:http://www.constructionworld.in/News.aspx?nId=JjDft4lL3daEe1VT5gZ7Tg==

1) Forum Mall Intelligent Building Details:

Floor Area: 3, 50, 000 Sq. ft. (plus 3, 00, 000 Sq. ft. parking)

Developer: Prestige Group

Intelligence Provided: Building Management System (BMS)

BMS Provider: Trend Control Systems, Honeywell](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-184-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

B. Case Study – 2 [Ebene Cyber Tower One, Mauritius]

Figure 4: Ebene Cyber Tower One, Mauritius

Source:http://www.constructionworld.in/News.aspx?nId=JjDft4lL3daEe1VT5gZ7Tg==

1) Management Committee:

Architect: C R Narayana Rao (CRN)

Intelligence Provided: Integrated Building Management System

Provider: Race Technologies

Cost of System: 1.75 to 2 Crore for the Building Management Systems (BMS)

2) System Details

Ebene Cyber City, Mauritius was awarded the Intelligent Building of the year by the

Intelligent Community Forum, USA in 2005. It uses an Integrated Management System

conceived and designed by C. R. Narayana Rao (CRN) and implemented by Race

technologies.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-186-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

occupants. And it can also exhibits key attributes of environmental sustainability to

benefit present and future generations.

Though intelligent buildings have a positive impact on the environment, people and

economy, there can be still a wide scope for enhancement. Owing to the continuous,

evolving technological progress that intelligent buildings can be a part of demands

further exploration.

REFERENCES

[1] Atkin, B., 1988. Progress towards Intelligent Building in Atkin, B. (ed.) Intelligent Buildings- Applications

of IT and Building Automation to High Technology Construction Projects. London: Unicom Seminars

limited.

[2] Akkermans H., Ygge F., and Gustavsson R., “HOMEBOTS: Intelligent Decentralized.

[3] Bann J. J., Irisarri, G. D., Mokhtari S., Kirschen D.S. and Mille, B. N., "Integrating Applications in an

Energy Management System", IEEE Expert 12(6), pp. 53-59, 1997.

[4] Chappells, H., 2010. Comfort, well-being and the socio-technical dynamics of everyday life Intelligent

Buildings International, 2(4), pp.286-298.

[5] Chen, J., Ma, Y., Jeng, T. and Chang, C., 2010. An assessment of user needs for intelligent living space.

Intelligent Buildings International, 2(1), pp.20-40.

[6] Clements-Croome, D., 1997. What do we mean by intelligent buildings? Automation in Construction.

[7] Clements-Croome, D. (ed.) 2004. Intelligent Buildings: Design, Management and Operation. London:

Thomas Telford.

[8] “Evolution of the office building in the course of the 20th century: Towards an intelligent building”

Elz˙bieta Niezabitowska* and Dorota Winnicka-Jasłowska Faculty of Architecture, Silesian University of

Technology, Gliwice, Poland

[9] Frost and Sullivan, 2009. The Bright Green Buildings - Convergence of Green and Intelligent Buildings

Continental Automated Buildings Association (CABA).

[10]Gray, A., 2006. How smart are Intelligent Buildings?

[11] “Green Building” Sustainability Shapes the Future of Building, MGS Architecture September - October

2012

[12]Harrison, A., Loe, E. and Read, J., 1998. Intelligent Buildings in South East Asia. London: Taylor &

Francis Routledge.

[13]Himanen, M., 2003. The Intelligence of Intelligent Buildings: The Feasibility of the Intelligent Building

Concept in Office Buildings. Doctor of Science in Technology Thesis, Helsinki University of Technology.

[14]Mazza, P., 2008. Making green buildings intelligent: how to link green buildings and the Smart Grid

[online].

[15]Moore, C.A., 2009b. Intelligent Buildings Are Green [online].

[16]Matsunawa, K. and Nohara, F., 1994. Intelligent building saves energy. ASHRAE Journal January, pp.38-

40.

[17]Matthew, P., Mukherjee, M. and Gupta, V., 2009. The Performance of Intelligent Buildings in India. The

Institution of Engineers (India) Journal, 90(April).](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-188-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

[18]Sharples, S., Callaghan, V. and Clarke, G., 1999. A Multi-Agent Architecture for Intelligent building

sensing and control. Sensor Review, 19(2), pp.135-140.

[19]Services for Energy Management”, Fourth International Symposium on the Managementof Industrial and

Corporate Knowledge (ISMICK’96), 1996.

[20]http://propertybytes.indiaproperty.com/index.php/architecture-interiors/intelligent-buildings

[21]http://iopscience.iop.org/journals

[22]http://nreionline.com/technology/smart_buildings/

[23]http://en.wikipedia.org/wiki/Intelligent_home#Natural_lighting

[24]http://www.tefma.com/infoservices/papers/2001/Dearlove.ppt

[25]https://www.google.co.in/?gws_rd=cr&ei=SCnzUu_-I4WVrAfmw4Eg#q=intelligent+building+images

[26]http://www.constructionworld.in/News.aspx?nId=JjDft4lL3daEe1VT5gZ7Tg==](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-189-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

2. It isadvisable to inform adjoining neighbours prior to the demolition so that they may close

windows or take othermeasures.

3. Before demolition is commenced, and also during the progress of such work, all electrical

cables or apparatuswhichis liable to be a source of danger, other than a cable or apparatus

used for the demolition works shall bedisconnected.

4. During the progress of demolition, the work shall be under the continuous supervision of

the demolisher or ofan experienced foreman.

5. Unless otherwise expressly approved, demolition shall be executed storey by storey

commencing at the roofand working downward.

6. When the demolition site adjoins a street or public walkway, a 2.4 meter high solid

hoarding shall be erected.

7. The demolished material shall not be allowed to remain on any floor or structure if the

weight of the materialexceeds the safe carrying capacity of the floor or structure.

8. Dust creating material, unless thoroughly dampened shall not be thrown or dropped from

the building, butshallbe lowered by hoisting apparatus or removed by material chutes.

9. Chutes shall be completely enclosed and a danger sign shall be placed at the discharge end

of every chute.

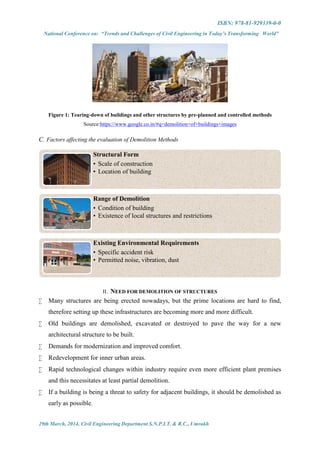

IX.CONCLUSION

Type of demolition method can depend upon various factors such as site condition, type of

structures, age of building, height of the building and the economy.

Explosive demolition can be preferred method for safely and efficiently demolishing the

larger structures.

For small buildings, that are only two or three stories high, demolition canbea simple

process.

While demolition by any method, the safety measures as precautions should be taken.

REFERENCES

[1] Carlo De Pauw, Erik K.Lauritzen, “Disaster Planning, Structural Assessment, Demolition and Recycling”,

First edition 1994, ISBN 0-203-62648-6 Master e-book ISBN, ISBN 0-203 63038-6 (Adobe eReader

Format), ISBN 0 419 19190 9 (Print Edition), © 1994 RILEM, Taylor & Francis, London.

[2] CBS Statline (2008a), Residential buildings by region. http://statline.cbs.nl

[3] CBS Statline (2008b), Changes in the dwelling stock. http://statline.cbs.nl

[4] Code of practice for Demolition of Buildings by Building Departments of Hong Kong in 2004.

[5] Erik K. Lauritzen, “Demolition and Reuse of Concrete and Masonry”, First edition 1994, ISBN 0-203-

62687-7 Master e-book ISBN, ISBN 0-203-63071-8 (Adobe e-Reader Format), ISBN 0 419 18400 7 (Print

Edition), E & EN SPON, Chapman & Hall, © 1994 RILEM, 24–27 October 1993, Odense, Denmark.

[6] Gruis, V. & N. Nieboer, (2004), “Asset Management in the Social Rented Sector”, Dordrecht (Kluwer).

[7] Itard L. & F. Meijer, 2009, “Towards a sustainable Northern European housing stock”, Amsterdam (IOS

Press).

[8] Jonge, T. de (2005), “Cost effectiveness of sustainable housing Investments”, Delft (DUP).](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-204-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

[9] Klunder, G. (2005), “Sustainable solutions for Dutch housing: Reducing the environmental impact of new

and existing houses”, Delft (DUP).

[10]Kohler, N. & U. Hassler (2002), “The building stock as a research object in Building Research &

Information”, 30(4).

[11]Ljubljana.Awano, H. (2005), “Towards the sustainable use of building stock”, Paris (OECD).

[12]MVROM (2008), INFO-Wonen, http://www.vrom.nl/infowonen

[13]Thomsen A. & K van der Flier (2002), Updating the Housing Stock, The Need for Renovation Based-

Approaches, in “Housing Cultures – Convergence and Diversity”, ENHR Conference 2002, Vienna.

[14]Thomsen A. (2007), “The New Building Assignment: Old Stock, New Markets”, Era build Event" 2007,

29-30 October 2007, Amsterdam (TU Delft).

[15]Prof. ChimayAnumba, Dr. Barbara Marino, Prof. Arie Gottfried, “Health and safety in refurbishment

involving and structural instability”, (Research 204).

[16]Tom Harris, “An article on How Building Implosions work”.

[17]Wassenberg F. (2006), “Motives for Demolition, in: “Housing in an expanding Europe”, ENHR Conference

2006.

[18]Y.Kasai. “Demolition Methods and Practice”, Proceedings of the Second International RILEM Symposium,

Tokyo, Japan. Chapman and Hall, London, UK 1988.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-205-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

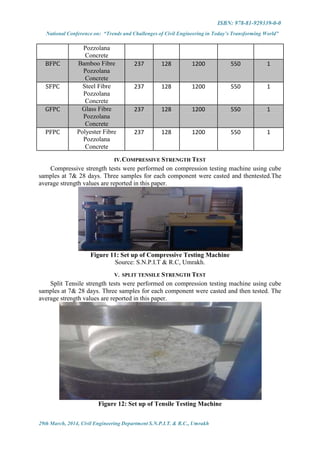

TABLE V: CHEMICAL PROPERTIES OF SCBA

Constituent Volume (%)

SiO2 50.64

CaO 4.11

Al2O3 4.83

Fe2O3 2.60

MgO ----

SO3 2.48

K2O ----

LOI 35.33

Source: Tested at Geo Test House, Baroda.

III.DESIGN MIX METHODOLOGY

A. Mortar Mix Proportion

A Mortar mix 1:3 was considered as per IS: 12269 -2013 method and was used to prepare the test samples.

The design mix proportion is done below in the tables.

TABLE VI: MIX PROPORTION FOR MORTAR

For 1 Cube Water Cement Sand

By Weight [gm] 90 ml 200 600

TABLE VII: CEMENT REPLACEMENT BY SCBA IN MORTAR

Sr.No. Mortar Type Description of Mortar

1. AM Normal Mortar (1:3)

2. MBC1 5% Replacement By SCBA

3. MBC2 10% Replacement By SCBA

B. Concrete Mix Proportion

A Concrete M25 grade was designed as per IS: 10262-2009 method and was used to prepare the test

samples. The design mix proportion is done below in the tables.

TABLE VIII: MIX DESIGN PROPORTION FOR CONCRETE

For 1 m3

Water Cement Fine Aggregate Coarse Aggregate

By Weight [kg] 200 L 400 665 1085

TABLE IX: CEMENT REPLACEMENT BY SCBA IN CONCRETE

Sr. No. Concrete Type Description of Concrete

1. AC Normal Concrete (M25)

2. CBC1 5% Replacement By SCBA

3. CBC2 10% Replacement By SCBA](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-210-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

REFERENCES

PAPERS:-

[1] AbdolkarimAbbasi& Amin Zargar, “Using BagasseAshInConcreteAsPozzolana”Middle-East

JournalofScientificResearch, ISSN 1990-9233, Vol.13, Issue 6, PP: 716-719, 2013.

[2] Lavanya M.R, Sugumaran.B and Pradeep.T, “An Experimental Study on the Compressive Strength of

Concrete By Partial Replacement of Cement With Sugarcane Bagasse Ash” International Journal of

Engineering Inventions ISSN: 2278-7461, ISBN: 2319-6491, Vol. 1, Issue 11, PP: 01-04, December2012.

[3] NuntachaiChusilp, NapongsatornLikhitsripaiboon and Chai Jaturapitakkul, “Development of Bagasse Ash

As A Pozzolanic Material In Concrete” Asian Journal on Energy and Environment, ISSN 1513-4121,

August 2009.

[4] R.Srinivasan&K.Sathiya, “Experimental Study on Bagasse Ash In Concrete” International Journal For

Service Learning In Engineering, ISSN 1555-9033, Vol. 5, No. 2, Pp. 60-66, Fall 2010.

IS CODES:-

[5] IS516-1959,“MethodsofTestsforStrengthofConcrete”, Bureau ofIndianStandards, New Delhi.

[6] IS 4031 -1988, “Methods for Physical Tests for Hydraulic Cement”, Part 6- Determination of

Compressive Strength of Hydraulic Cement Other than Masonry Cement, Bureau ofIndianStandards, New

Delhi.

[7] IS10262-2009,“ISMethod ofMixDesign”,Bureau of Indian Standards, New Delhi.

[8] IS 12269 -2013, “Specification for 53 Grade OPC”, Bureau ofIndianStandards, New Delhi.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-215-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

3 Initial setting

time (hours,

min)

91 min 30 minimum

4 Final setting

time

(hours, min)

211

min

600 maximum

5 Compressive

strength

58

N/mm2

53 N/mm2

minimum

C. Fine Aggregate

Those fractions from 4.75 mm to 150 micron are termed as fine aggregate. The river

sand is used as fine aggregate conforming to the requirements of IS: 383. The river sand

is washed and screened, to eliminate deleterious materials and over size particles.

TABLE III: - PROPERTIES OF FINE AGGREGATE

Property Fine

Aggregate

(River sand)

Fineness modulus 3.1

Specific Gravity 2.767

Water absorption (%) 1.2

Bulk Density (gm/cc) 1.78

D. Water

Water is an important ingredient of Mortar as it actually participates in the chemical

reaction with cement. Since it helps to from the strength giving cement gel, the quantity and

quality of water is required to be looked into very carefully.

I. DESIGN MIX METHODOLOGY

TABLE IV: - MIX DESIGN PROPORTIONS

Wate

r

Cemen

t

Fine aggregate

(River sand)

By Weight,

[gms]

86 200 600

TABLE V: - % REPLACEMENT OF CEMENT BY MICRO SILICA

Sr.

No.

Types of

Mortar

Description of Mortar

1 A1 River sand Mortar (1:3)

2 H1 10% Cement Replacement by Micro Silica](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-218-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

3 H2 30% Cement Replacement by Micro Silica

4 H3 50% Cement Replacement by Micro Silica

TABLE VI: - DESIGN MIX PROPORTIONS FOR MORTAR (1:3)

Types of

Mortar

W/C

ratio

% Replacement of Cement

by Micro Silica

Design Mix Proportions For Mortar

(1:3) (by Weight in gms)

C F.A.R. Micro Silica

A1 0.45 0 200 600 -

H1 0.45 10% 180 600 20

H2 0.45 30% 140 600 60

H3 0.45 50% 100 600 100

W= Water, C= Cement, F. A.R. = Fine Aggregate Regional

A. Compressive strength

Compressive strength tests were performed on compression testing machine using cube

samples. Three samples per batch were tested with the average strength values reported in

this paper. The loading rate on the cube is 35 N/mm2

per min. The comparative studies were

made on their characteristics for cement mortar ratio of 1:3 with partial replacement of

cement with Micro Silica as 0%, 10%, 30% and 50%.

Fig 1: Set up of Compressive Testing Machine

B. Water Absorption Test

The 70.7 mm x 70.7 mm x 70.7mm size cube after casting were immersed in water for

28 days curing. These specimens were then oven dried for 24 hours at the temperature85°C

until the mass became constant and again weighed. This weight was noted as the dry weight

(W1) of the cylinder. After that the specimen was kept in water at 85°c for 24 hours. Then

this weight was noted as the wet weight (W2) of the cylinder.

% water absorption = [(W2– W1) / W1] x 100

Where,

W1 = Oven dry weight of cubes in grams

W2 = after 24 hours wet weight of cubes in grams.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-219-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Fig 4: Average Sorptivity at 28 Days for Micro Silica Mortar

IV.CONCLUSION

As the % Replacement of Micro Silica Increase Compressive Strength is Decreasing

Optimum Replacement level is Found at 10 %

As the cost of Micro Silica is High so this Mortar Can only be used when Strength is

Required and Cost can be ignored

As the Compressive strength increase Water absorption and Sorptivity are Decreased

For Cost Effectiveness some extra additives like Fly Ash can be Used with Micro

Silica

This type of Mortar can be used for Structural Purpose rather than for Low cost

construction

V.ACKNOWLEDGMENT

The heading of the Acknowledgment and References must not be numbered. It should be like

in Following Format.

The authors are thankfully acknowledge to Mr. J.N.Patel, ChairmainVidyabharti Trust, Mr.

K.N.Patel, Hon. Secretary, Vidyabharti Trust, Dr. H.R.Patel, Director, Dr.J.A.Shah,

Principal, S.N.P.I.T.&R.C.,Umrakh, Bardoli, Gujarat,India for their motivational &

infrastructural supports to carry out this research.

REFERENCES

[1] Atis, C. D. (2003). “Accelerated carbonation and testing of mortar made with fly ash.” Construction and

Building Materials, Vol. 17, No. 3, pp. 147-152.

[2] Bai j., Wild S, Sabir BB (2002) “Sorptivity and strength of air-cured and water cured PC-PFA-MK mortar

and the influence of binder composition and carbonation depth”. Cement and mortar research 32:1813-

1821.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-222-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

[3] Bentz, D., Ehlen, M., Ferraris, C., and Garboczi, E. "Sorptivity-Based Service Life Predictions for Mortar

Pavements." 181–193.

[4] Caliskan, S. (2006). "Influence of curing conditions on the sorptivity and weight change characteristics of

self-compacting mortar." The Arabian Journal for Science and Engineering, 31(1), 169-178.

[5] Claisse, P. A. (1997). "Absorption and Sorptivity of Cover Mortar."Journal of Materials in Civil

Engineering, 9(3), 105-110.

[6] Dias, W. P. S. (2000). "Reduction of mortar sorptivity with age through carbonation."Cement and Mortar

Research, 30(8), 1255-1261.

[7] Deepa A Sinha, Dr.A.K.Verma, Dr.K.B.Prakash (2012) “Sorptivity and waste absorption of steel fibers

reinforced ternary blended mortar”. International journal: global research analysis

(GRA),volume:1,issue:5,oct2012,issn no:2277-8160.

[8] Gonen, T. and Yazicioglu, S. (2007). “The influence of compactionpores on sorptivity and carbonation of

mortar.” Construction andBuilding Materials, Vol. 21, No. 5, pp. 1040-1045.

[9] Güneyisi, E. and Gesog˘lu, M., (2008). “A study on durability properties ofhigh-performance mortars

incorporating high replacement levelsof slag.” Materials and Structures, Vol. 41, No. 3, pp. 479-493.

[10] Hall, C. (1977). "Water movement in porous building materials--I.Unsaturated flow theory and its

applications."Building and Environment, 12(2), 117-125.

[11] Hall, Christopher; Hoff, William D (2012). Water transport in brick, stone and mortar, 2nd edn.

London and New York: Taylor and Francis. http://www.routledge.com/books/details/9780415564670/.

[12] JayeshkumarPitroda, Dr. F S Umrigar (2013), “Evaluation of Sorptivity and Water Absorption of

Concrete with Partial Replacement of Cement by Thermal Industry Waste (Fly Ash)” International Journal

of Engineering and Innovative Technology (IJEIT) Volume 2, Issue 7, January 2013, ISSN: 2277-3754, ISO

9001:2008 Certified, pp-245-249.

[13] Prof. JayeshkumarPitroda, Dr. L.B.Zala, Dr.F.S.Umrigar (2013), “ Durability of concrete with Partial

Replacement of Cement by Paper Industry Waste (Hypo Sludge)” International Journal of Innovative

Technology and Exploring Engineering (IJITEE) , ISSN: 2278-3075, Volume-2, Issue-3, February 2013 /

101-104

[14] Philip, John R (1957). "The theory of infiltration: 4. Sorptivity and algebraic infiltration equations".

Soil Science 84: 257-264.

[15] Rushabh A. Shah, Prof. JayeshkumarPitroda (2013), “Effect of Pozzocrete as Partial Replacement

with Cement in Mortar” International Journal Global Research Analysis, (GRA), Volume: 2, Issue: 1, Jan

2013, ISSN No 2277 – 8160, pp-44-46.

[16] Rushabh A. Shah, Prof. JayeshkumarPitroda (2013), “Pozzocrete: Modern Material Partially

Replaced with Cement in Mortar” International Journal of Innovative Technology and Exploring

Engineering (IJITEE), ISSN: 2278-3075, Volume-2, Issue-3, February 2013 / 105-108

[17] Rushabh A. Shah, Prof. JayeshkumarPitroda (2013), “Fly Ash Class F: Opportunities for Development

of Low Cost Mortar” International Journal of Innovative Technology and Exploring Engineering (IJITEE),

ISSN: 2278-3075, Volume-2, Issue-4, February 2013 / 112-115](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-223-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

[18] Rushabh A. Shah, Prof. JayeshkumarPitroda (2013), “Effect of Water Absorption and Sorptivity on

Durability of Pozzocrete Mortar” IJESE.

[19] Sulapha, P., Wong, S. F., and Wee, T. H., and Swaddiwudhipong, S.(2003). “Carbonation of mortar

containing mineral admixtures.”Journal of Materials in Civil Engineering, Vol. 15, No. 2, pp. 134-143.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-224-320.jpg)

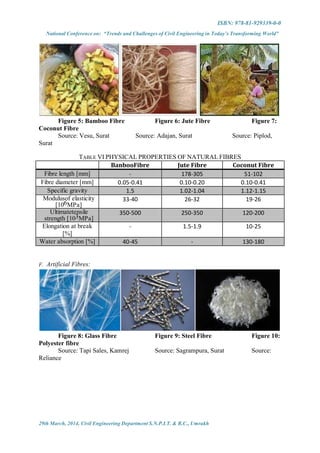

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

Loss on Ignition (%) 4.63 %

Figure 4: Fly Ash

Source: - S.N.P.I.T & R.C, Umrakh

III.DESIGN MIX METHODOLOGY

A mix of 1:3 was taken. The design mix proportion is mentioned below:

TABLE V: MIX DESIGN PROPORTION

For 1m3

Cube Water/Cement Ratio Water (Litre) Cement (Kg) Coarse Aggregate (Kg)

By Weight [kg] 0.25 136 543 1629

TABLE VI: TYPES OF PERVIOUS CONCRETE

Sr. No. Mortar Type Description of Mortar Water/Cement Ratio

1. AC Conventional Pervious Concrete (Kapchi 20mm)

0.25

2. AF 10% Replacement of Cement by Fly Ash (Kapchi 20mm)

3. DC Conventional Pervious Concrete (Grit 10mm)

4. DF 10% Replacement of Cement by Fly Ash (Grit 10mm)

IV.COMPRESSIVE STRENGTH TEST

Compressive strength test was performed on compression testing machine using cube

samples at 7 days. Three samples for each component were casted and then tested. The

average strength values are reported in this paper.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-229-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

[1] ThusharaPriyadarshana, Colombo, Shri Lanka, “ Pervious concrete – a sustainable choice in civil

engineering and construction”

[2] http://myscmap.sc.gov/marine/NERR/pdf/PerviousConcrete_pavements.pdf

[3] http://www.perviousconcrete.com/maintenance_prevention.htm

[4] http://en.wikipedia.org/wiki/Pervious_concrete

[5] http://theconstructor.org/concrete/pervious-concrete-futuristic-solution-to-urban-runoff/5289/

[6] http://www.nbmcw.com/articles/roads/5529-pervious-concrete-pavement-for-parking-areas-pathways-

sustainable-porous-and-storm-waterdrainage.html

[7] http://www.nbmcw.com/articles/roads/25313-pervious-concrete-a-solution-to-stormwater-runoff.html.

[8] http://www.nrmca.org/research_engineering/Documents/.

[9] http://www.flyash.com/data/upimages/press/TB.29%20Fly%20Ash%20in%20Pervious%20Concrete.pdf

[10]IS516-1959, “Methods of Tests for Strength of Concrete”, Bureau of Indian Standards, New Delhi.

[11]IS 4031 -1988, “Methods for Physical Tests for Hydraulic Cement”, Part 6- Determination of Compressive

Strength of Hydraulic Cement Other than Masonry Cement, Bureau of Indian Standards, New Delhi.

[12]IS10262-2009, “IS Method of Mix Design”, Bureau of Indian Standards, New Delhi.

[13]IS 12269 -1987, “Specification for 53 Grade OPC”, Bureau of Indian Standards, New Delhi.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-232-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

sawdust, canola meal, and coconut shell.Copper is one such metal that requires considerable

attention. Industrial wastewater from textile, leather tanning, electroplating, pigmentation and

dyes contain copper in high concentration.

The application of low-cost adsorbents obtained from plant wastes as a replacement for costly

conventional methods of removing heavy metal ions from wastewater has been reviewed. It is

well known that cellulosic waste materials can be obtained and employed as cheap adsorbents

and their performance to remove heavy metal ions can be affected upon chemical treatment.

Fly ash, Peanut hulls, Banana peels, Neem leaves, Tea waste, Sugar cane bagasse, Rise husk,

Saw dust, Coconut husk, Soybean hulls, Cotton seed hulls are low cost adsorbents.[8]

Table 1. Heavy metal removal efficiency (%) of different adsorbents

Adsorbent

Avg. Heavy metal removal efficiency (%)

Cr(VI) Ni(II) Cu(II) Zn(II) Cd(II) Hg(II) Pb(II)

Rice husk carbon 98.5 92.3 85.5 78.3 66.2 58.1 57.8

Fly ash 85.3 67.5 78.4 74.9 65 55 51

Peanut hulls 87.1 72.5 57.8 83 71.4 61 56.3

Banana peels 91 81.3 81 73.8 62.8 70 61.8

Neem leaves 83 77.6 84.3 75.7 69 56.4 71.6

Tea waste 85.4 71.9 87.1 85.1 73.5 70 65.2

Sugar cane bagasse 99 87 94.2 75.3 71.5 61.7 66.5

Saw dust 84 75 91 57.8 59.7 62.7 55.8

Coconut husk 75 68 89.3 77.6 67.5 71.9 70

Cotton seed hulls 78 82 90 62.7 70 65.5 61

(Source: Low Cost Adsorbents for Removal of Heavy Metals from Wastewater ISSN (Online) 2319-183)

Introduction & effect of Copper

Copper is a persistent, bio-accumulative and toxic heavy metal which does not break

down in the environment, it is not easily metabolized and can harm human health. The

various potential sources of copper pollution are metallurgical and metal finishing, corrosion

inhibitors in cooling and boiler systems, drilling mud’s catalysts, primer paints, fungicides,

copper plating and pickling, corrosion of copper piping, copper releases from vehicle brake

pads.[2]

Acute poisoning from ingestion of excessive copper can cause temporary gastrointestinal

distress with symptoms such as nausea, vomiting, and abdominal pain. Liver toxicity has

been seen in doses high enough to cause death. High levels of exposure to copper can cause

destruction of red blood cells, possibly resulting in anemia.

Mammals have efficient mechanisms to regulate copper stores such that they are generally

protected from excess dietary copper levels. However, at high enough levels, chronic](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-234-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

overexposure to copper can damage the liver and kidneys. Symptoms of liver toxicity

(jaundice, swelling, pain) usually do not appear until adolescence [3].

II. LITERATURE REVIEW

Dr. P. AkhilaSwathanthra, Dr. B. SarathBabu, M. SrinivasaRao, Dr.V.V.BasavaRao has studied

thatAdsorption behavior of copper from waste water has been investigated in this paper using

Bagasse. Copper is highly toxic metal ion and considered as a priority pollutant released from

various chemical industries like electroplating mixing activities, smelting, battery

manufacture, etc. In the present paper, the experimental results carried out in batch adsorption

process using treated Bagasse with synthetic samples prepared in laboratory were presented.

The various parameters such as solution pH, initial copper concentration, Temperature and

adsorbent dosage on the adsorption of Cu (II) were studied and presented. It was found that

the adsorption data were fitted well by Langmuir isotherm. The Langmuir adsorption

capacity was estimated at 4.75 mg/g for Bagasse. The maximum removal of Copper is above

93% was observed at pHof 5 for Bagasse in 100ppm Copper solution [1].

N Prapurna and M Viswanathamhas studied that the Adsorption Kinetics for the

simultaneous and selective removal ofCr (VI) and Cu (II) ions fromaqueous mixture was

investigated using sugarcane bagasse. Batch studies were performed at room temperature at

three different initialconcentrations of each metal ion to be present in the test sample: 10ppm,

30ppm and 50ppm. Theavailable literature for the removal of each of these heavy metal ions

when present individually inaqueous solutions was applied in these studies. Accordingly,

water washed and sun dried sugarcanebagasse retained on 200 micron-mesh, was used for the

study at a dosage of 0.4 g/l of the test sample.ThepH of the test samples varied from 7.05

initial values to 8.09 at equilibrium, during all the batchstudies. The study has revealed that

the adsorbent had higher selectivity to Cu (II) ions in comparisonto the Cr (VI) ions at the

study conditions. The experimental results fit well with linearized Freundlich Adsorption

Isotherm Model [4].

PatilKishor P., Patil Vilas S., NileshPatil, Motiraya Vijay has investigated that the

efficiency of removing copper ions and Zinc ions from Copper Chloride and Zinc Chloride,

using naturally based adsorbents like Sugarcane Bagasse. Batch adsorption studies show that

the sugarcane bagasse has great ability for extracting metallic ions from wastewater samples.

The factors affectingcopper ion adsorption by sugarcane bagasse were determined to be](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-235-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

initial concentration and pH of the solution, the results showed that bagasse were found to be

an attractive low costalternative for the treatment of wastewater. A good efficiency to remove

toxic metal ions was achieved by usage of such by-product. The acid modified sugarcane

bagasse and Cu (II) solution were kept in contact for various time periods 10, 20, 30, 60 min.

The % removal of Cu was obtained 85-90%. Various time periods (1-4) hrs % removal is 60-

70% [5].

Thomas Anish Johnson, Niveta Jain, H C Joshi and Shiv Prasadstudied that use of

agricultural and agro-processing industry waste (Sugarcane bagasse) as metal adsorbents

from wastewater. Modified materials displayed better adsorption capacity of some was

comparable with that of commercial activated carbons and synthetic resins. Agricultural

wastes are low cost adsorbents and can be viable alternatives to activated carbon for

treatment of metal contaminated wastewater. Batch adsorption of sugarcane bagasse reached

equilibrium by 60 min of contact and achieved 60% removal of Cu (II); a highest up to 30.9

mg/g for Cu (II) at pH 5.5 [7].

Shaliza Ibrahim, Piarapakaran Subramaniam and Nasim Ahmad Khanhas studied that the

adsorption process is being widely used by various researchers for the removal of heavy

metals from waste streams and activated carbon has been frequently used as an adsorbent.

The objective of this study is to contribute in the search for less expensive adsorbents and

their utilization possibilities for various agricultural waste by-products such as sugarcane

bagasse, rice husk, oil palm shell, coconut shell, coconut husk etc. for the elimination of

heavy metals from wastewater. At an adsorbent dose of 0.8 g / 50 ml is sufficient to remove

80 – 100% Cr (VI) from aqueous solution having an initial metal concentration of 20mg/l at a

pH value of 1.The maximum removal obtained was around 99.8% at pH 2. The data for all

the adsorbents fit well to the Freundlich isotherm [6].

III. MATERIALS AND METHODS

Preparation of Adsorbent

The adsorbent was selectedfor removal of Copper by sugarcane bagasse. It is a waste

product from sugar mill mainly composed of glucose, cellulose, pentose, and lignin.

Adsorbent (Sugarcane bagasse) collected from Sugar industry. Firstly the adsorbent was

washed with distilled water and dried at room temperature to avoid the release of color by

adsorbent into the aqueous solution. The activation of adsorbent is carried out by treating it

with concentrated sulphuric acid (0.1N) and is kept in an oven maintained at a temperature

range of 150ºC for 24hr. Again is washed with distilled water to remove the free acid and put](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-236-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

in to oven for removal of moisture and then adsorbent is passed from 500 micron mesh size

and collected for experimental use.

Table 2. Physical and chemical characteristics of bagasse

Physical

Characteristics

Value

Chemical

Characteristics

Value (%)

Bulk density, kg/m3

254.55 Glucose 40 - 50%

Moisture (%) 6.5 Cellulose 45.1

Ash content (%) 1.08 Hemicelluloses 25.6

Porosity (%) 0.51 Lignin 12.7

Surface area, m2

419.5 Other organic material 4.3

Loss on drying (%) 18.1

(“REMOVAL OF HEAVY METALS EMPLOYING BAGASSE” ISSN: 2249-4189.)

Case study: Removal of Heavy Metals Employing Bagasse

Synthetic solution of Cu2+ were prepared50 ppm of stock Solution of CuCl2.0.775 gm of

CuCl2 is taken in 500 ml distilled water, so1000 ppm CuCl2 Solution is Prepared. Pipette out

25 ml solution from it and add to 475 ml distilledwater to prepare 500 ml of 50 ppm CuCl2

solution.The activation of adsorbent is carried out by treating it with concentrated sulphuric

acid (0.1N) and is kept in an oven maintained at a temperature range of 150ºC for 24hr.

The batch experiments are carried out in 250ml borosil conical flasks by shaking a pre-

weighed amount of the adsorbent with 100ml of the aqueous Copper solutions of known

concentration and pH value. The metal solutions were agitated on a magnetic stirrer 120 rpm

for a desired time. The samples were withdrawn from the stirrer at the pre determined time

intervals and adsorbent was separated by filtration. Copper concentration in the filtrate was

estimated using AAS.The experiments were carried out by varying the copper concentration

in the solution, pH. The adsorbent dosage gm/100ml for contact time. The adsorbent was

separated by filtered using filter paper.

% removal of copper = (C initial – C final) × 100/ C initial

Where C initial and Cfinal are the initial and final copper concentrations, respectively.[9]

IV. RESULTS AND DISCUSSION

Effect of pH:

Successful application of the adsorption technique demandsinnovation of cheap, non-

toxic, easily and locally availableadsorbents of known kinetic parameters and

sorptioncharacteristics.The uptake of Cu2+

ion as afunction of hydrogen ion concentration was](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-237-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming World”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

REFERENCES

[1] Dr. P. AkhilaSwathanthra, Dr. B. SarathBabu, M. SrinivasaRao, Dr.V.V.Basava “REMOVAL OF

COPPER FROM AQUEOUS SOLUTIONS BY USING SUGAR CANE BAGASSE” ISSN: 2320 1932

[2] HamizahMokhtar, NorhashimahMorad “Hyperaccumulation of Copper by Two Species of Aquatic Plants”

2011 International Conference on Environment Science and Engineering IPCBEE vol.8 (2011) © (2011)

IACSIT Press, Singapore.

[3] New Hampshire Department of environmental services “Environmental fact sheet” pg. no. 1-3.

[4] N Prapurna and M Vlswanatham “Adsorption kinetics of sugarcane bagasse for selective removal of Cr

(VI) and Cu (II) from aqueous solutions”

[5] PatilKishor P., Patil Vilas S., NileshPatil, Motiraya Vijay “Adsorption of Copper (cu 2+) & Zinc (zn2+)

Metal Ion from Waste Water by Using Soybean Hulls and Sugarcane Bagasse as Adsorbent” ISSN: 2279-

0543

[6] Shaliza Ibrahim, PiarapakaranSubramaniam and Nasim Ahmad Khan “Elimination of Heavy Metals from

Wastewater Using Agricultural Wastes as Adsorbents” Malaysian Journal of Science 23: 43 - 51 (2004)

[7] Thomas Anish Johnson, Niveta Jain, H C Joshi and Shiv Prasad “ Agricultural and agro-processing wastes

as low cost adsorbents for metal removal from wastewater” Vol. 647-658

[8] Zodape.G.V, Dhawan.V.L, Wagh.R.R, Sawant.A.S “Contamination of heavy metals in seafood marketed

from Vile Parle and Dadar markets of suburban areas of Mumbai (west coast of) India” International

Journal Of Environmental Sciences Volume 1, No 6, 2011.

[9] RaazMaheshwari, A K Chauhan, MahendraVyas, Bina Rani “REMOVAL OF HEAVY METALS

EMPLOYING BAGASSE” ISSN: 2249-4189.](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-239-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

V.REFERENCES

[1] “Advancing and Integrating Construction Education, Research & Practice” August 4-5, 2008,

Karachi,, Pakistan

[2] Balaguru, P. N. (2005), “Nanotechnology and Concrete: Background, Opportunities and Challenges.”

Proceedings of the International Conference – Application of Technology in Concrete Design,

Scotland, UK, p.113-122.

[3] Bigley C. and Greenwood P. (2003). “Using Silica to Control Bleed and Segregation in Self-

Compacting Concrete.” Concrete, vol. 37, no. 2, p.43-45

[4] D.A. Koleva, “NANO MATERIALS FOR CORROSION CONTROL IN REINFORCED

CONCRETE”, TUDelft

[5] Dhir, R. K., Newlands, M. D., and Csetenyi, L. J. (2005). “Introduction.” Proceedings of the

International Conference – Application of Technology in Concrete Design, Scotland, UK, p. IV.

[6] Kuennen, K. (2004). “Small Science Will Bring Big Changes To Roads.” Better Roads

[7] Li, G. (2004). “Properties of High-Volume Fly Ash Concrete Incorporating Nano-SiO2.” Cement and

Concrete Research, vol.34, p.1043-1049.

[8] Liu, R., Zhang, Z., Zhong, R.; Chen, X.; Li, J.(2007) “Nanotechnology Synthesis Study: Research

Report”

[9] Mann, S. (2006). “Nanotechnology and Construction,” Nanoforum Report. www.nanoforum.org, May

30, 2008.

[10]MMFX Steel Corp. http://www.mmfx.com/products.shtml, May 30, 2008.

[11]Nanopedia (2008). “Carbon Nanotubes.” http://nanopedia.case.edu/image/nanotubes.jpg, January 16,

2008.

[12]RADU OLAR, NANOMATERIALS AND NANOTECHNOLOGIES FOR CIVIL ENGINEERING,

Universitatea Tehnică „Gheorghe Asachi” din Iaşi Tomul LIV (LVIII), Fasc. 4, 2011 Secţia

CONSTRUCŢII. ARHITECTURĂ

[13] Saurav, “Application Of Nanotechnology In Building Materials”, International Journal of Engineering

Research and Applications (IJERA) ISSN: 2248- 9622 www.ijera.com Vol. 2, Issue5, September-

October 2012, pp.1077-1082

[14]Song G, Gu H., Mo Y. L., Hsu T. T. C. and Dhonde H., , Concrete structural health monitoring using

embedded piezoceramic transducers, Smart Materials and Structures, 16: 959-968, 2007

[15] V. Kartik Ganesh, “NANOTECHNOLOGY IN CIVIL ENGINEERING”, European Scientific Journal November

edition vol. 8, No.27 ISSN: 1857 – 7881 (Print) e - ISSN 1857- 7431

[16]Yashar Moslehy, Haichang Gu, Abdeljalil Belarbi, Y.L. Mo and Gangbing Song; “Smart Aggregate-

Based Damage Detection of Circular RC columns under Cyclic Combined Loading”

[17]Zhi Ge, Zhili Gao, “Applications of Nanotechnology and Nanomaterials in Construction”, First

International Conference on Construction In Developing Countries (ICCIDC–I)](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-249-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

′

= ∗ ( − )

Where,

A= area of the slab,

= thickness of monolith slab,

= specific weight of concrete,

=specific weight of water,

2. Bribiesca et al (1979): Obtain an expression for the time average of the square of the

total vertical force acting on the slab SP

2

as

= ∗ ∗

With

=

∝ +∝

∗ [ ∝ + (∝ − )] ∗ [ + ( − )]

Where,

= variance of the total pressure acting on the upper face of the slab.

= coefficient of distribution of pressure,

The thickness is given by,

=

−

( )

Where,

= standard deviation of the depth of flow at the centre of graviry of the area A, in m,

= useful life of concrete lining of the slab in seconds,

= main frequency of purpose fluctuations, Hz.

1. Toso et al. (1988): State that for practical purposes, the pressure fluctuations tend to

approach a definite limit, of the order of 80 to 90 % of the head.

By selecting an appropriate value of Cp from table given by him, the maximum

deviation from the mean pressure is worked out as

∆ =

This deviation pressure ∆ is assumed to act on the centre of an area 8y1 * 13y1 moving out of

the centre of the area, the pressure would drop off to the mean pressure.

The uplift force is given by

′

= ∆

Where,](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-259-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

REFERENCES

[1] Building Construction by Dr. B.C. Punmia, Ashok Kumar Jain, Arun Kumar Jain

[2] IS 6313 (Part 1) :1981 CODE OF PRACTICE FOR ANTI-TERMITEMEASURES IN BUILDINGS

[3] IS 6313 (Part 2) :2001 CODE OF PRACTICE FOR ANTI-TERMITEMEASURES IN BUILDINGS

[4] www.termites101.org

[5] www.google.com

[6] www.gujaratpest.com

[7] www.ipm.ucdavis.edu

[8] www.pestworld.org

[9] www.wikipedia.com](https://image.slidesharecdn.com/fullpaperproceeding-140331060233-phpapp02/85/Full-paper-proceeding-273-320.jpg)

![ISBN: 978-81-929339-0-0

National Conference on: “Trends and Challenges of Civil Engineering in Today’s Transforming W o r l d ”

29th March, 2014, Civil Engineering Department S.N.P.I.T. & R.C., Umrakh

REFERENCES

[1] JAMES. M. FISHER S.E, Steel conference, expansion joints, where, when and how?

[2] Expansion Joints in Buildings: Technical Report No. 65, http://www.nap.edu/catalog/9801.html

[3] Mohammad Iqbal, D. Sc., P.E., S.E., Esq. October, 2010

[4] Structural Design - Discussions on design issues for structural engineers… Joint Publication of NCSEA |

CASE | SEI

[5] Kris zielonkaP.eng. Technical manager situra INC., A study of Practices in design, detailing and water

proofing, expansion joint in North America.

[6] Technical note 63, joints in concrete buildings, sept 2004.

[7] Gurcharan Singh, Building construction and materials, standard book house, 12th edition 2012

[8] http://www.expertsmind.com

[9] http://www.pavement.com

[10] http://www.stpltd.com/html/Presentation/Sealants%20and%20Additives/ShaliSeal%20PS%20PG.pdf

[11] http://www.heidelbergcement.com/uk/en/hanson/products/blocks/technical_information/thermalite_move

ment_control.htm

[12] http://besser.tsoa.nyu.edu/impact/f95/Cdwa/MATERIAL.HTML

[13] http://www.nbmcw.com/articles/waterproofing-construction-chemicals/3202-treating-expansion-joints-

with-koster-joint-tape-system.html

[14] https://www.google.co.in/?gws_rd=cr&ei=llT3UpPSEoyCrgemnYHwDA#q=Wind+effect+on+buildings+i

mages

[15] https://www.google.co.in/?gws_rd=cr&ei=llT3UpPSEoyCrgemnYHwDA#q=Thermal+effect+on+building

s+images

[16] https://www.google.co.in/?gws_rd=cr&ei=llT3UpPSEoyCrgemnYHwDA#q=Loads+effect+on+buildings+

images