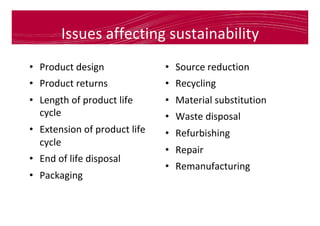

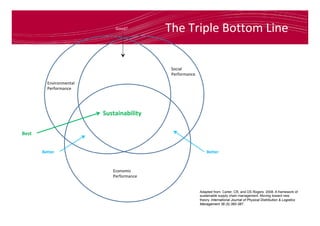

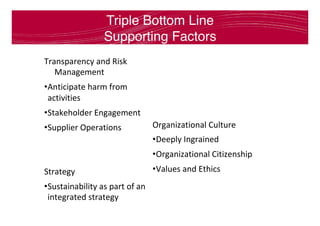

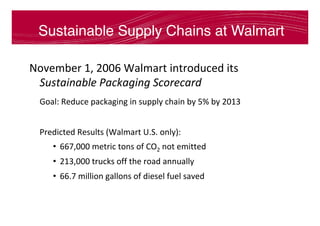

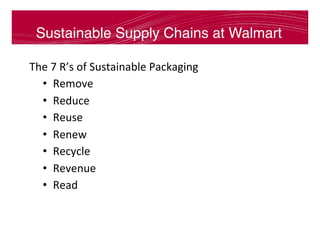

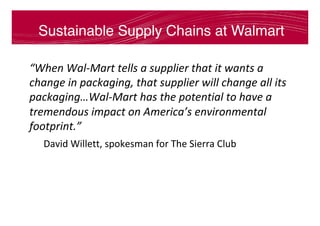

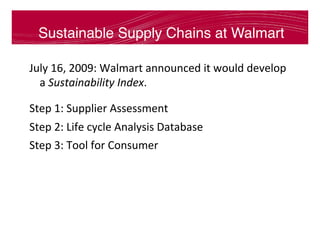

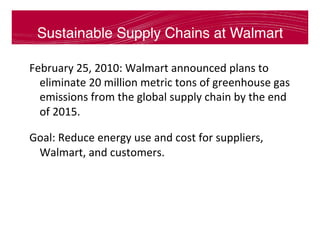

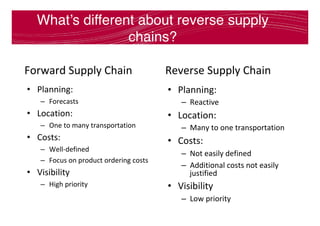

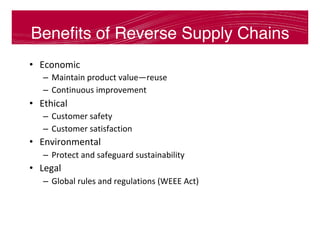

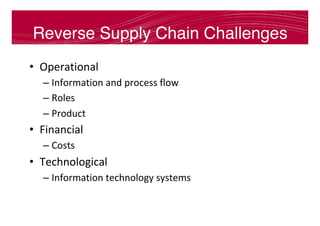

This document discusses developing sustainable supply chains. It defines supply chain management and sustainable supply chain management. There are several reasons why supply chains should strive to be sustainable, including to reduce costs and risks, manage reputational issues, and reinforce shareholder value. The document also discusses issues affecting sustainability across various stages of production and distribution. It emphasizes using a triple bottom line approach of evaluating environmental, social, and economic impacts. Examples are provided of sustainable supply chain initiatives undertaken by Walmart. Reverse supply chains and their benefits and challenges are also outlined.