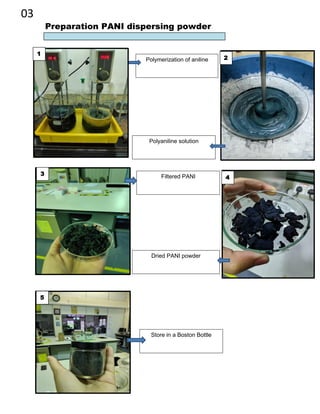

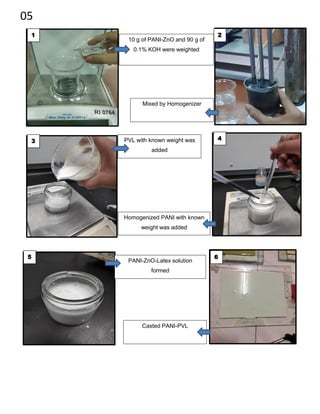

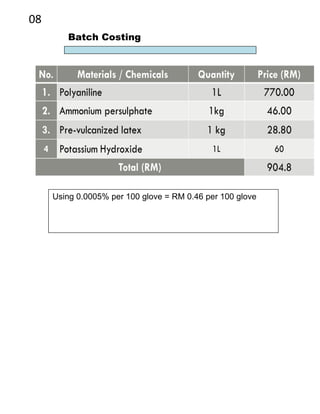

This document summarizes a research project on modifying natural rubber latex for surgical gloves. The objectives were to disperse polyaniline (PANI) powder into latex to study the effects on mechanical and dispersion properties. PANI was synthesized and characterized, finding it flocculated with particle sizes of 88-260 microns. PANI was then added to latex solutions at different loadings and the mixtures were cast into films. Mechanical testing found the large PANI particles affected dispersion and inconsistent properties. Adding PANI would cost an estimated RM 0.46 per 100 gloves. In summary, the research aimed to add PANI to latex to potentially enhance glove properties but found the large polymer particles hindered consistent dispersion and mechanical performance.