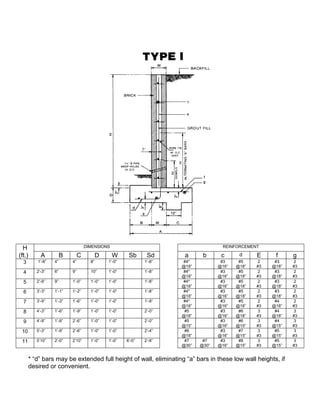

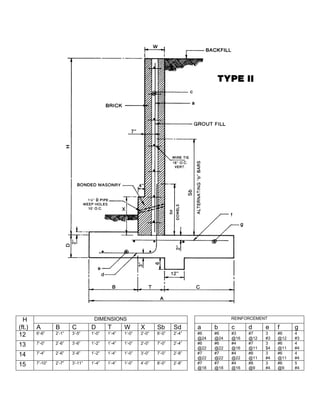

This document provides design specifications and construction details for reinforced brick masonry retaining walls ranging from 3 to 20 feet in height. It includes standard wall details with alternate footing designs for constrained spaces. Wall designs are categorized by height ranges and include dimensions, reinforcement requirements, and safety factor calculations. Footings are also detailed to accommodate various subsurface conditions. Instructions are provided for special cases like surcharged walls. The document aims to provide convenient standardized wall designs for designers and builders to reference.