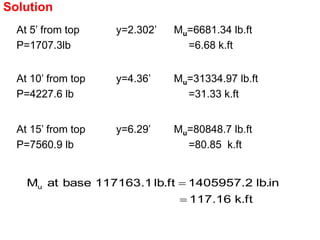

Retaining walls are used to hold back earth or loose materials where natural slopes cannot form due to space restrictions. There are several types of retaining walls including gravity, cantilever, counterfort, and buttress walls. Stability requirements for retaining walls include ensuring individual parts can resist forces, and the wall as a whole is stable against settlement, sliding, and overturning. Proper drainage is also important to consider in retaining wall design.

![Design of Heel Cantilever

Wu = (1.7) (120) (8) + (1.4) [18 x 120 + 2 x 150 ]

= 5076 lb/ft

ft

.

lb

76

.

88947

92

.

5

76

.

5

2

1

2

W

M

2

u

2

Vu = Factored shear a joint of stem and heel

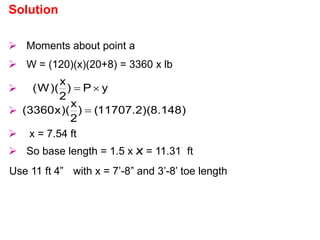

Solution

When the support reaction introduces compression into

the end region, then critical shear is at a distance d

from face of support. However, the support is not

producing compression, therefore, critical shear is at

joint of stem and heel.](https://image.slidesharecdn.com/retainingwalluol-230622091446-45876481/85/Retaining_Wall_UOL-pptx-43-320.jpg)

![Now Wu=(1.7)(120)(8)+(1.4)[(17.5)(120)+(2.5)(150)] = 5097 lb/ft

.

ft

.

lb

75

.

89315

)

92

.

5

)(

5097

(

2

1

M 2

u

005

.

0

f

200

00337

.

0

f

mR

2

1

1

m

1

psi

23

.

131

)

5

.

27

)(

12

)(

9

.

0

(

12

89315

bd

M

R

quired

Re

y

min

y

n

u

n 2

2

Solution

Design of Heel Cantilever](https://image.slidesharecdn.com/retainingwalluol-230622091446-45876481/85/Retaining_Wall_UOL-pptx-45-320.jpg)