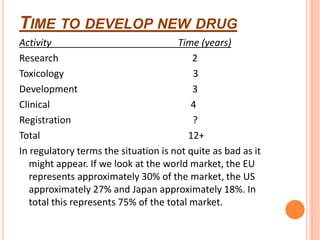

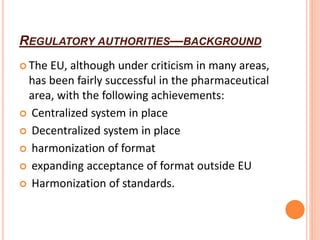

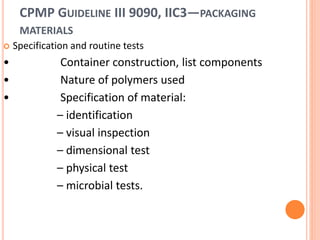

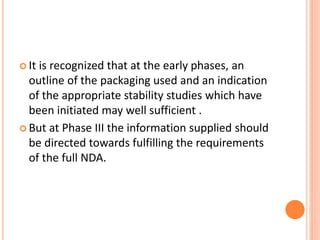

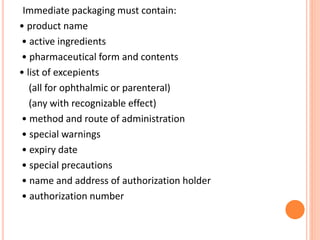

The document presents an overview of regulatory aspects related to pharmaceutical packaging, detailing the processes and standards in the European Union and the USA. It discusses the definitions of packaging, legal requirements for labeling, and the various procedures for drug evaluation in these regions. Additionally, it highlights the significance of packaging in protecting products and providing necessary information to consumers and regulatory bodies.