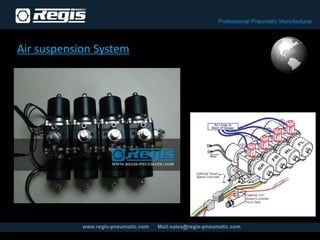

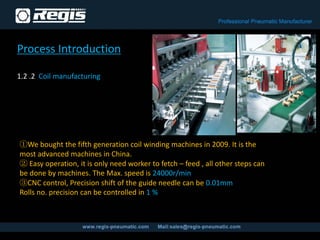

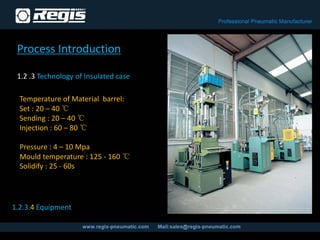

The document details the manufacturing process and features of solenoid valves produced by Regis, highlighting their importance in the company's history and technological advancements. Regis has a strong reputation, significant capital investment, and full self-production capabilities, particularly in air suspension systems for the automotive industry. The document also outlines the technical specifications and the machinery used in the production process, emphasizing the precision and customization available for their products.