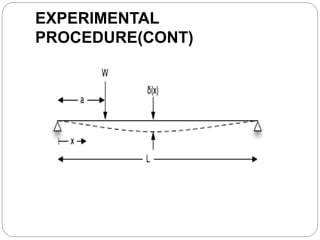

The document describes a final year project focused on analyzing reinforced concrete (RCC) beams using Abaqus for finite element analysis (FEA). Experiments comparing laboratory results with numerical analysis demonstrated that under reinforced beams show optimal performance and greater warning signs before failure. The study highlights the importance of utilizing advanced analytical models to improve the understanding of RCC behavior under various conditions.