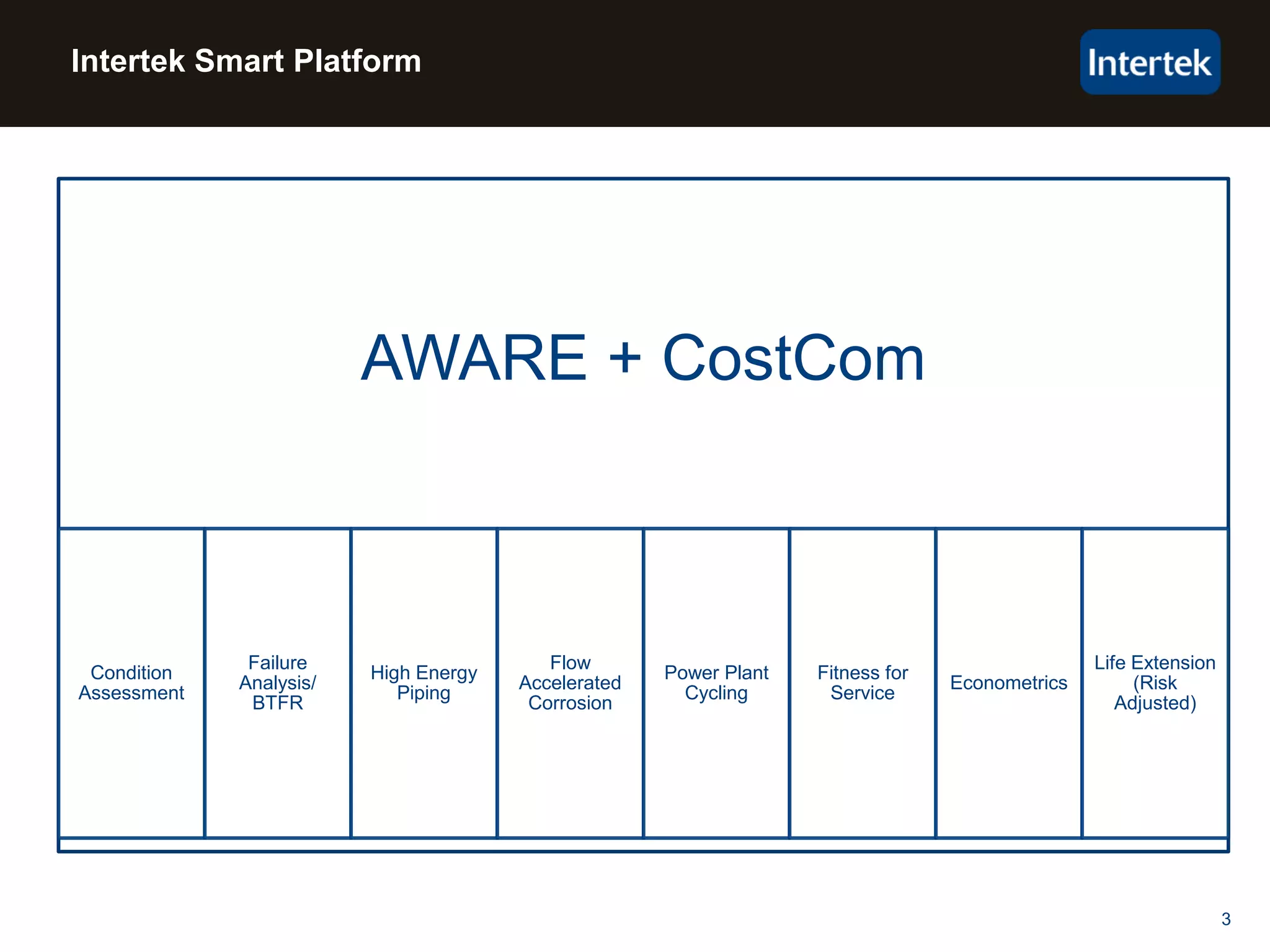

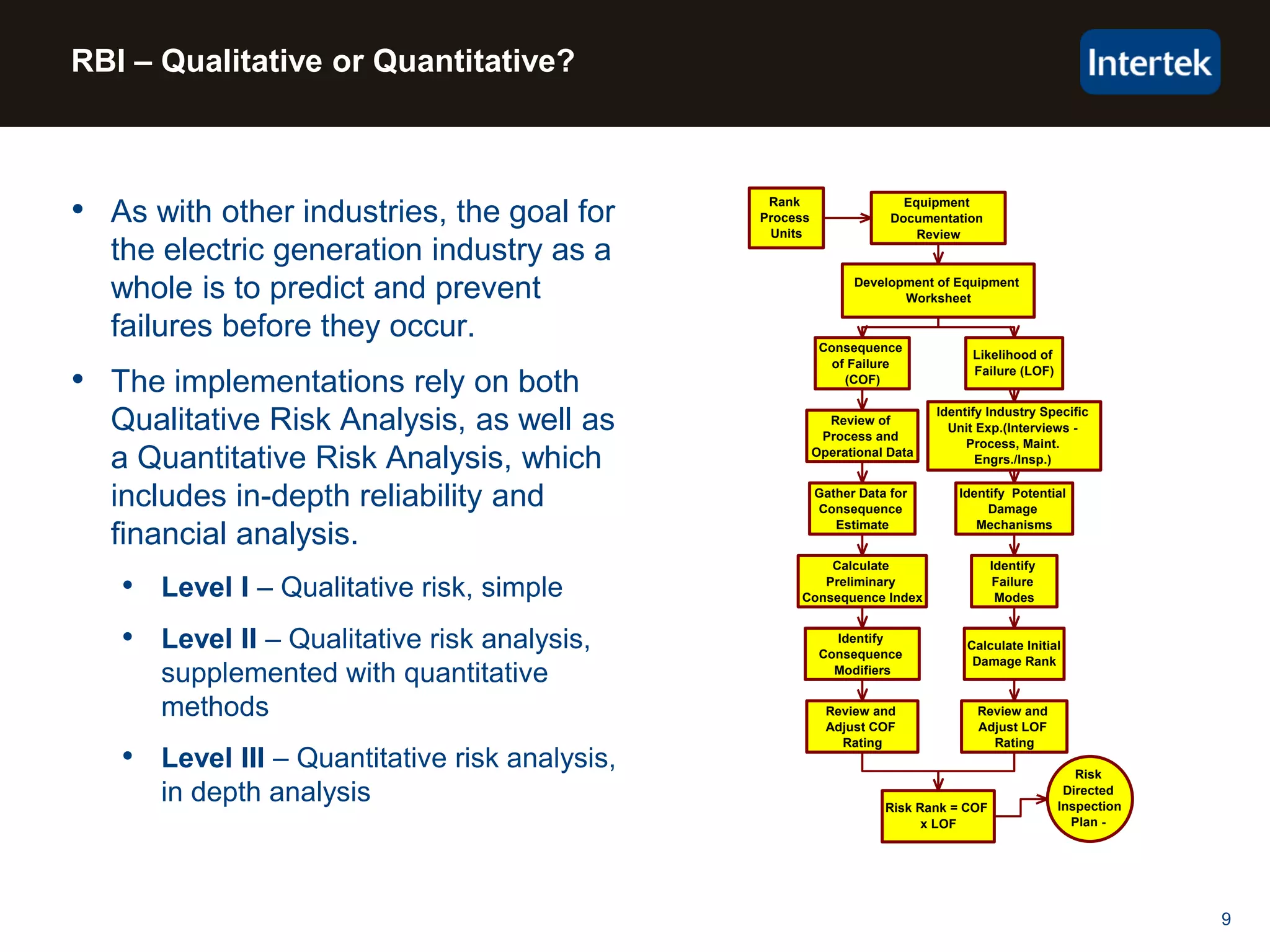

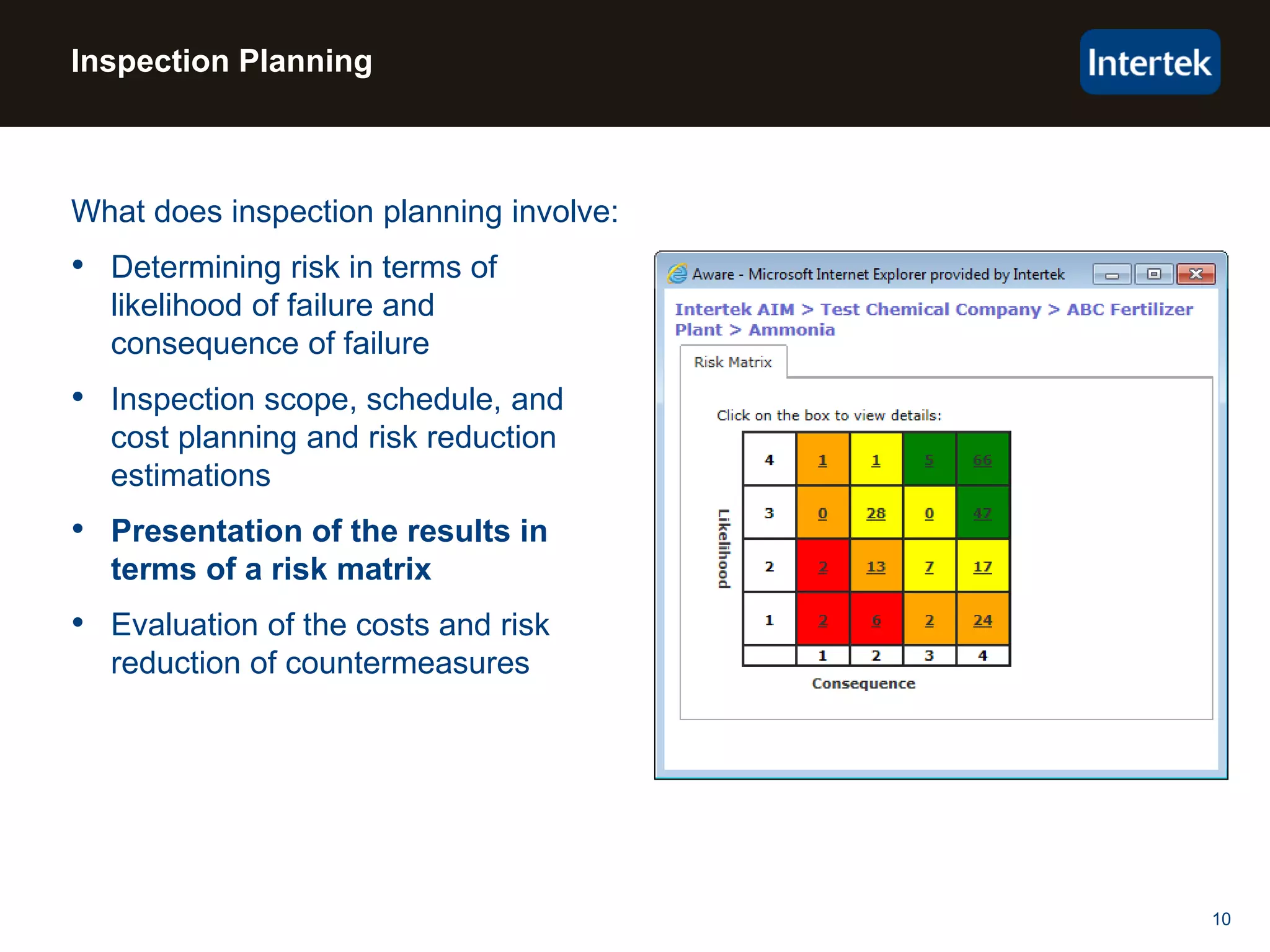

This document summarizes an Intertek presentation on risk-based inspection for power plants. It discusses how risk-based inspection (RBI) can improve safety and reliability while reducing costs. RBI involves assessing the risk of equipment failure by determining the likelihood and consequences of failure. This informs targeted inspection plans and risk reduction strategies. The document outlines Intertek's RBI methodology and software platform, which goes beyond basic RBI requirements to develop customized inspection and monitoring plans, organize historical data, and provide a flexible program to optimize equipment life.

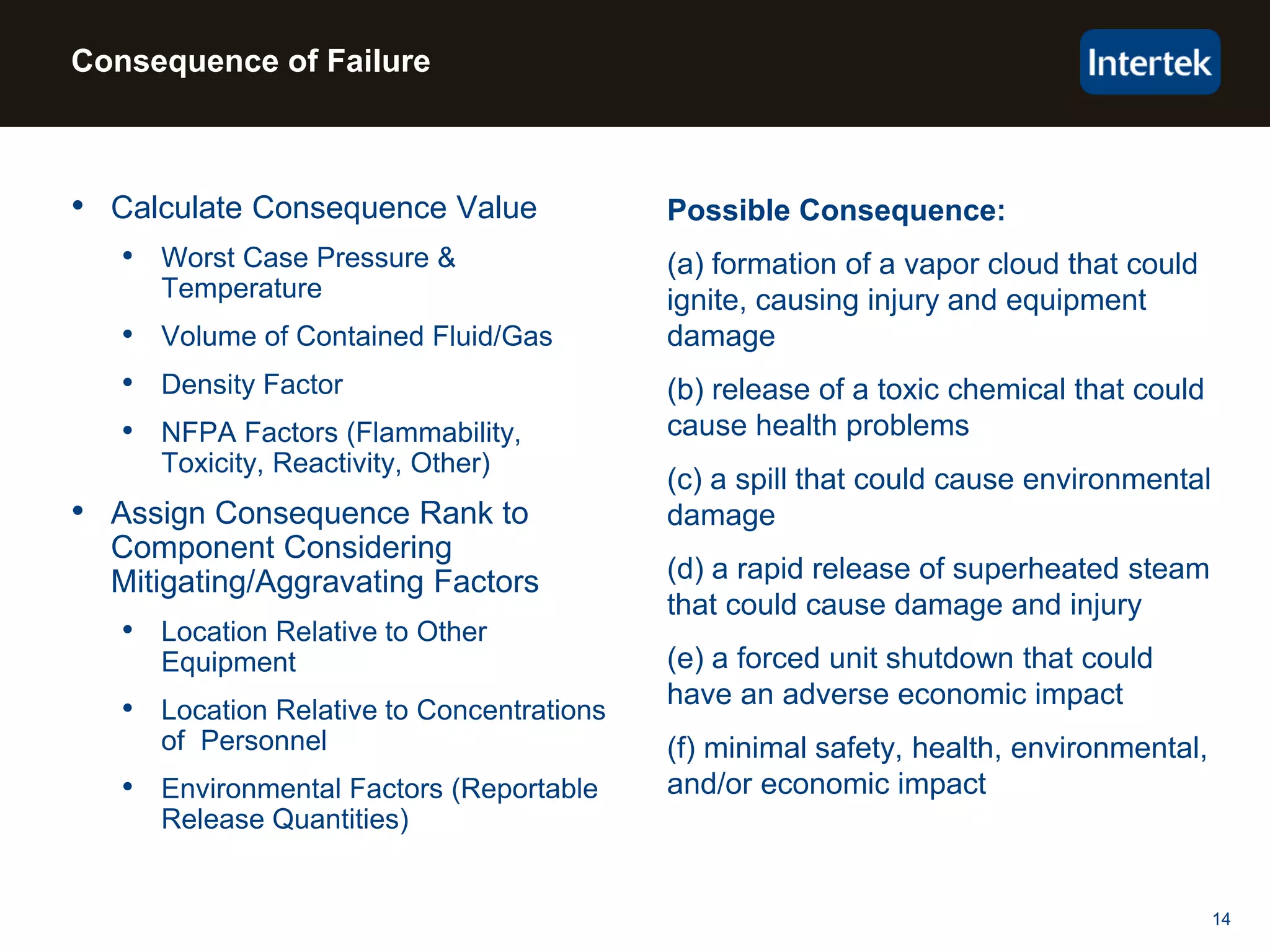

![11

Intertek Approach

AWARE

Decision

Analysis

No detection +

No Repair

Equipment

Failure

Equipment

Risk

Assessment

No detection +

No Repair

Detection + No

Repair

Detection +

Repair

Detection + No

Repair

Equipment

Failure

Equipment

Risk

Assessment

No detection +

No Repair

Detection + No

Repair

Detection +

Repair

No detection +

No Repair

Equipment

Failure

Equipment

Risk

AssessmentDetection +

Repair

Risk

Mitigation

Plan

Inspection

Plan

Risk Matrix

Data

Analysis

[Determine

POF/COF]

Data Input

in AWARE

Data

Collection](https://image.slidesharecdn.com/b490718b-9d68-4048-baf7-094443cd0e91-160707155201/75/RBI-for-Power-Generation-11-2048.jpg)

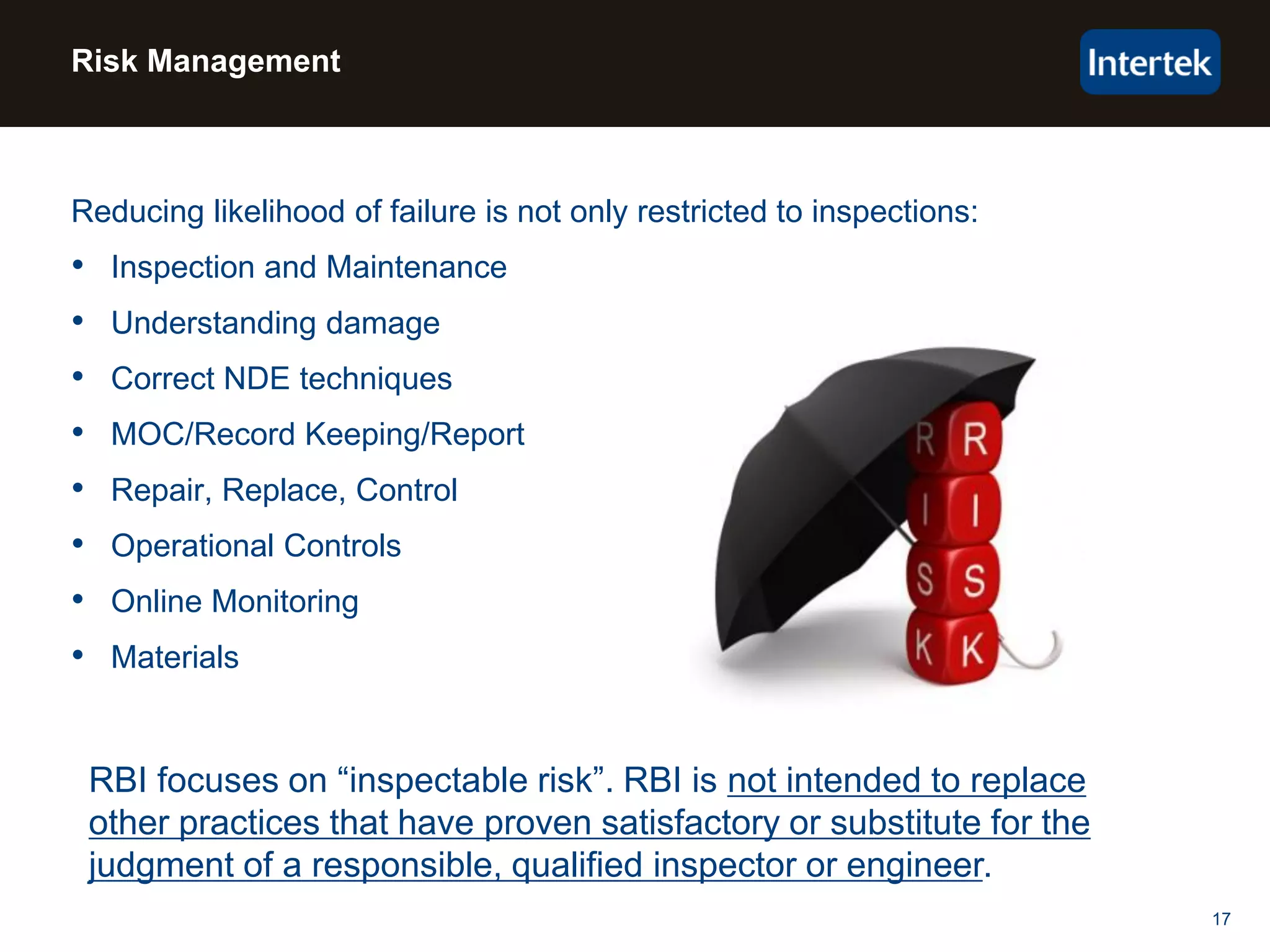

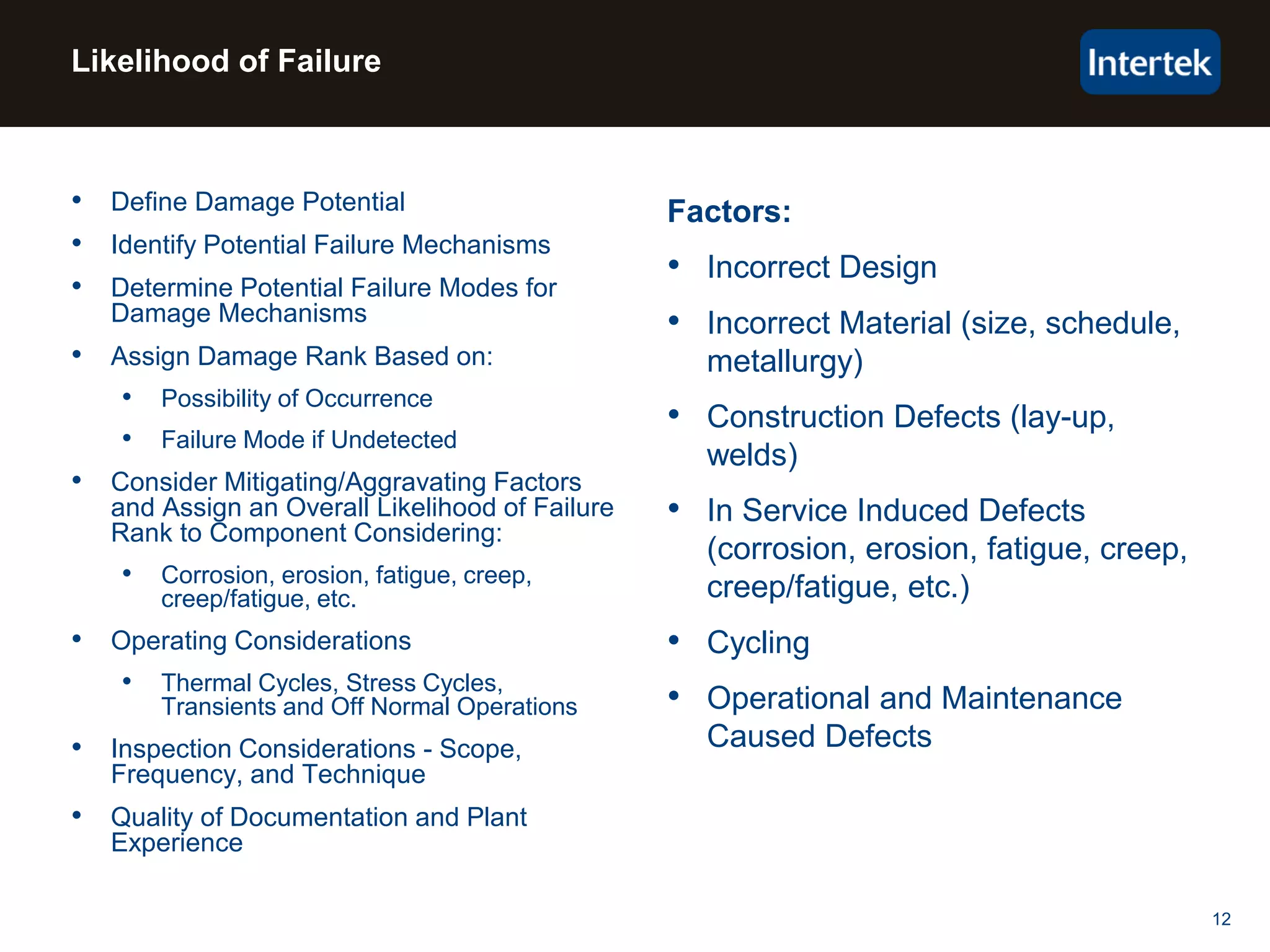

![13

− Reliability Models for

certain key equipment

(High Energy Piping or

Pressure Vessels),

where damage

mechanisms and

uncertainties are well

understood and

statistical distributions

are available. In this

scenario, the model uses

the following equation to

determine POF:

• 𝑃𝑓 𝑡 = 𝑔𝑓𝑓. 𝐷𝑓 𝑡 . 𝐹 𝑀,

where 𝑃𝑓 𝑡 is the function

of a generic failure

frequency 𝑔𝑓𝑓, damage

factor 𝐷𝑓(𝑡), and a

management system

factor 𝐹 𝑀

− Statistical Models. These

models are based on

generic data collected

either using frequencies

available in the AWARE

database or other models

developed by Intertek

Engineering. We will also

rely on EPRI data to

develop and determine the

POF.

• Where appropriate, two

parameter Weibull models

will be used to estimate

failure frequency, 𝑃𝑓 𝑡 =

1 − exp[−

𝑡

𝐶𝐿′

𝐵

] ; where:

CL’ is the updated

characteristic life and B is the

shape factor

• For some key boiler pressure

parts Intertek’s probabilistic

failure rate damage models

such as TUBETECH or

SAFESEAM, or SAFEGIRTH

will be used to estimate the

likelihood (i.e., probability,

frequency) of failure

− Expert Judgment. will be

relied upon when the

information on likely

damage mechanism or

failure frequency is

found inadequate.

Likelihood of Failure](https://image.slidesharecdn.com/b490718b-9d68-4048-baf7-094443cd0e91-160707155201/75/RBI-for-Power-Generation-13-2048.jpg)