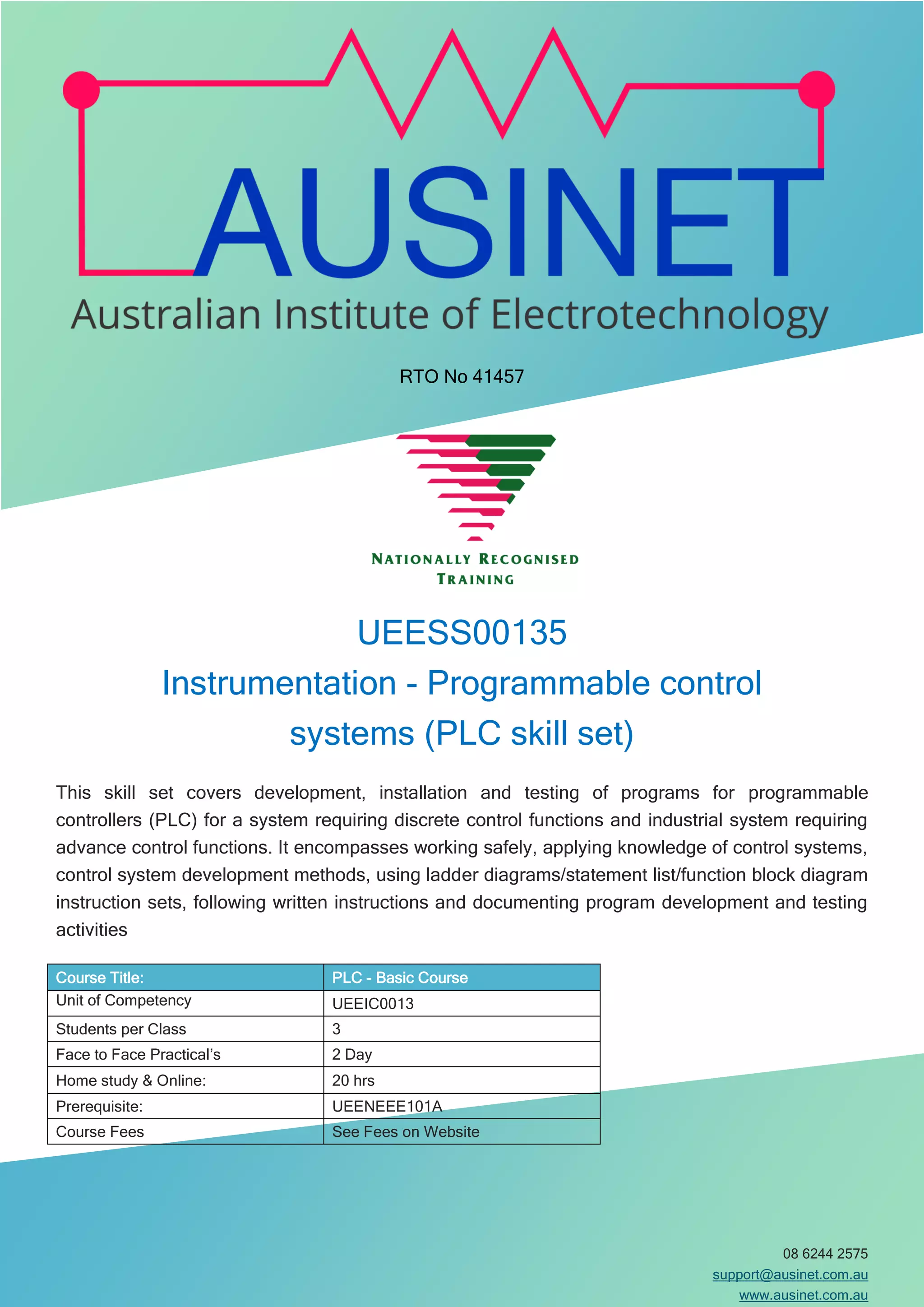

This document provides information about a training course on programmable logic controllers (PLCs). The two-day course covers developing, installing, and testing PLC programs for discrete control systems. Topics include ladder logic, timers, counters, input/output modules, and PLC installation requirements. Successful students will receive a statement of attainment for the unit of competency UEEIC0013 in developing discrete control programs for PLCs. The course is offered in Brisbane and Darwin with fees varying based on the number of accredited hours.