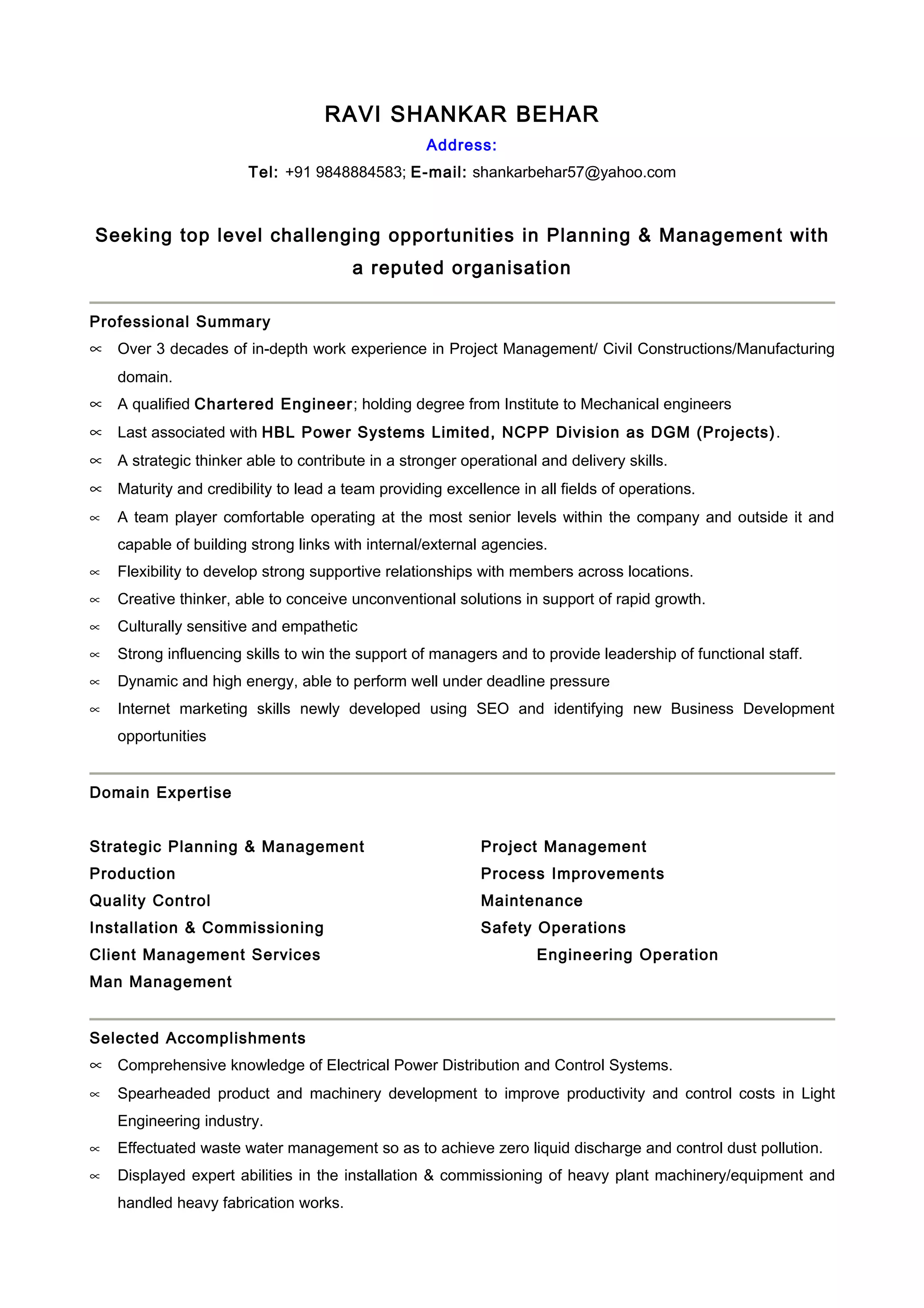

Ravi Shankar Behar is seeking a top-level, challenging opportunity in planning and management with over 3 decades of experience in project management, civil construction, manufacturing, and mechanical engineering. He holds an AMIE and has worked in roles such as DGM of Projects at HBL Power Systems and as a manager of fabrication shops and mechanical projects. He has expertise in areas like strategic planning, project management, production, quality control, and maintenance.