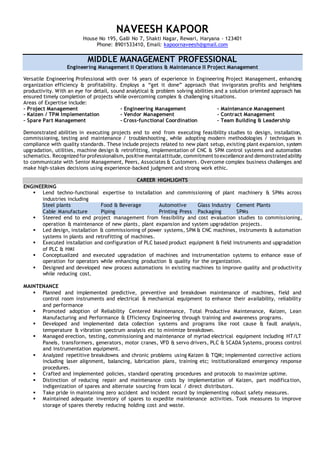

This document is a resume for Naveesh Kapoor, an engineering management and project management professional with over 16 years of experience. It summarizes his expertise in areas like project management, engineering management, maintenance management, and team leadership. It also provides details of his past work experience managing engineering projects, maintenance operations, and utilities across various industries. Key highlights of projects executed and achievements are mentioned.