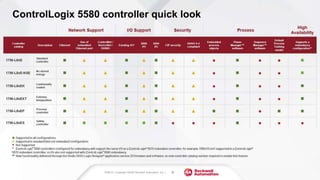

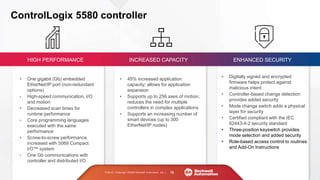

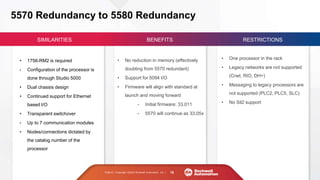

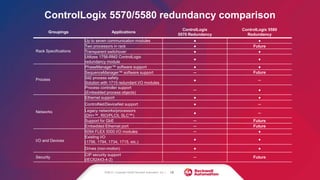

The document discusses Rockwell Automation's ControlLogix 5570 and 5580 controller portfolio. It provides an overview of the different controller options for micro, standard, and complex machines/processes. The ControlLogix 5580 controller offers increased capacity and performance over previous models, supporting up to 256 motion axes and 300 nodes. It provides enhanced security features. The document also describes the redundancy capabilities of ControlLogix 5580, which allows two processors in a rack for fault tolerance, and how this redundancy differs from the 5570 model.