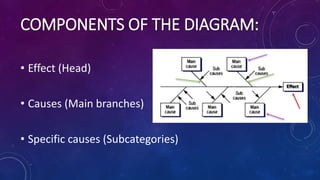

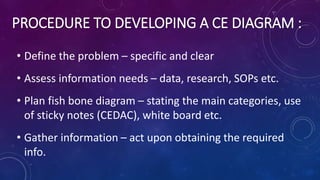

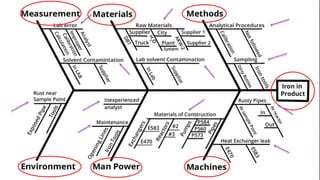

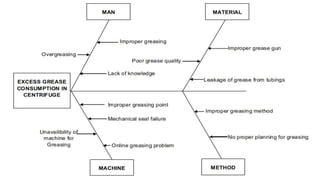

The document discusses the implementation of quality circles and CEDAC (Cause and Effect Diagram with the addition of cards) to improve quality in the food processing industry. It emphasizes the importance of voluntary collaboration among team members across various departments to identify and solve quality-related problems through structured methodologies like the PDCA cycle. A case study illustrates the successful application of these techniques in optimizing grease consumption in a manufacturing setting.