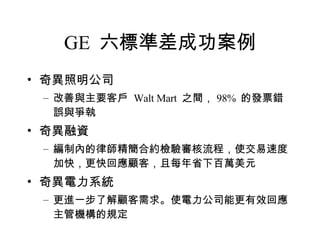

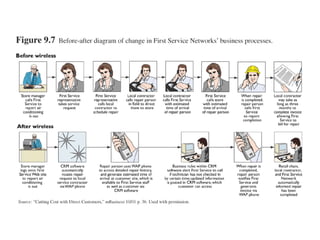

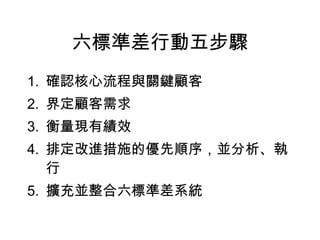

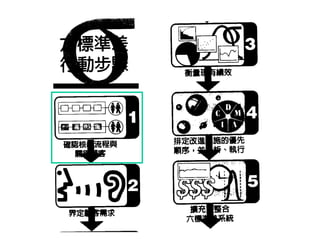

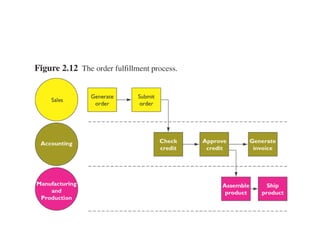

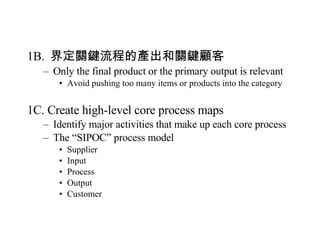

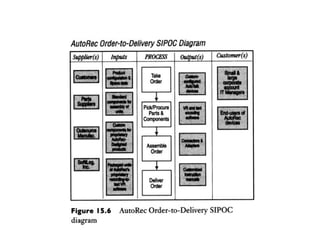

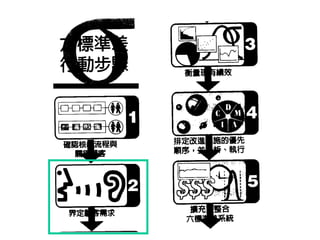

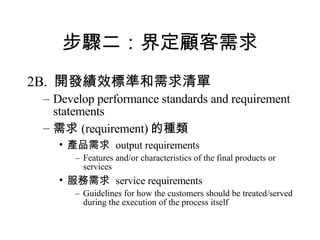

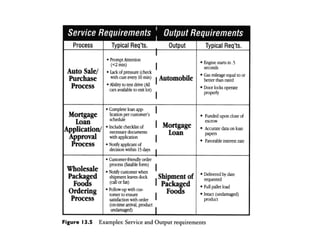

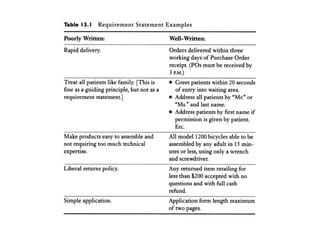

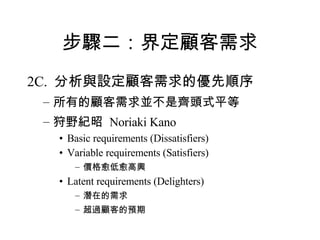

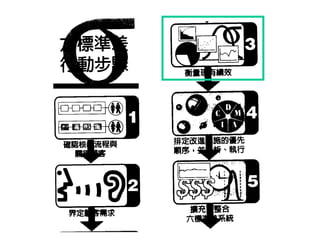

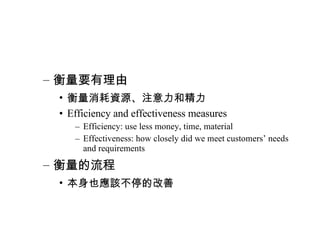

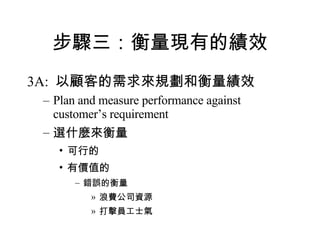

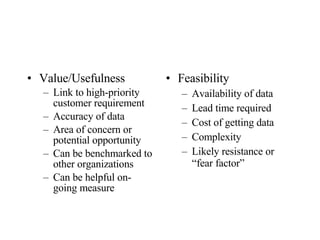

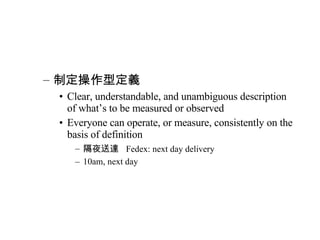

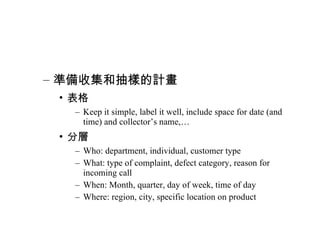

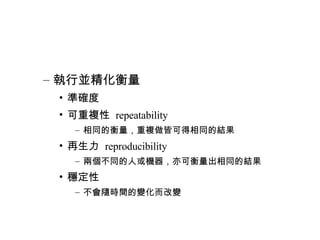

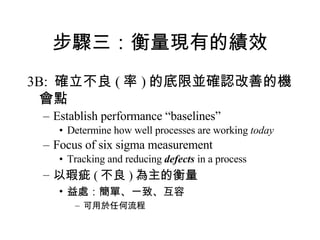

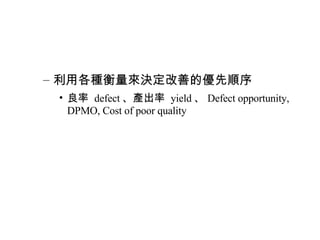

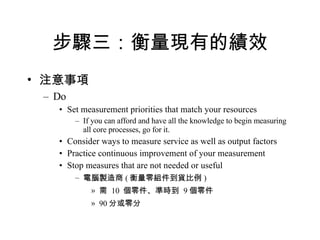

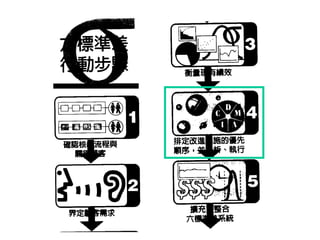

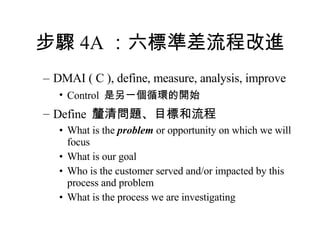

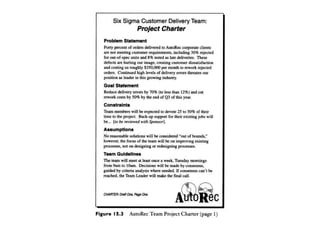

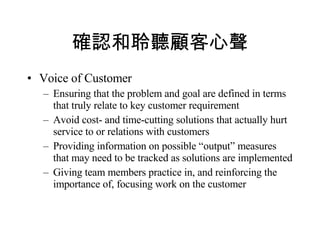

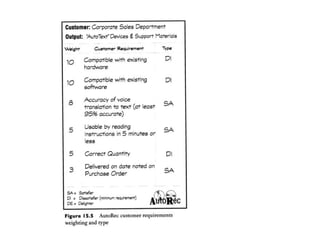

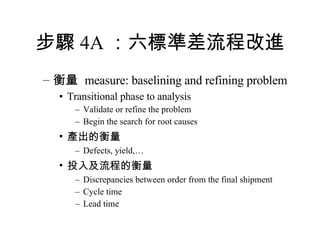

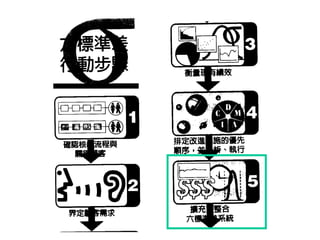

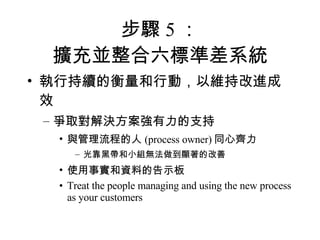

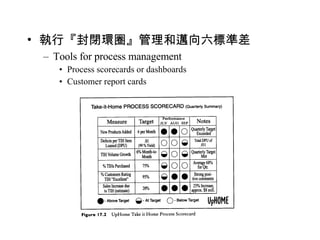

The document discusses the history and methodology of Six Sigma. It originated at Motorola in 1986 focusing on reducing defects and improving quality. It was later introduced to other companies by consultants and adopted widely, helping companies like GE significantly increase profits. Six Sigma emphasizes customer focus, data-driven decision making, process management, and cross-functional cooperation to drive improvements. The summary outlines the typical five steps of a Six Sigma project: 1) Identifying core processes and customers, 2) Defining customer requirements, 3) Measuring current performance, 4) Prioritizing improvement opportunities, and 5) Integrating Six Sigma throughout the organization.

![六標準差 郭倉義 中山企管 [email_address]](https://image.slidesharecdn.com/qm045-1212810265558927-9/75/QM-045-1-2048.jpg)