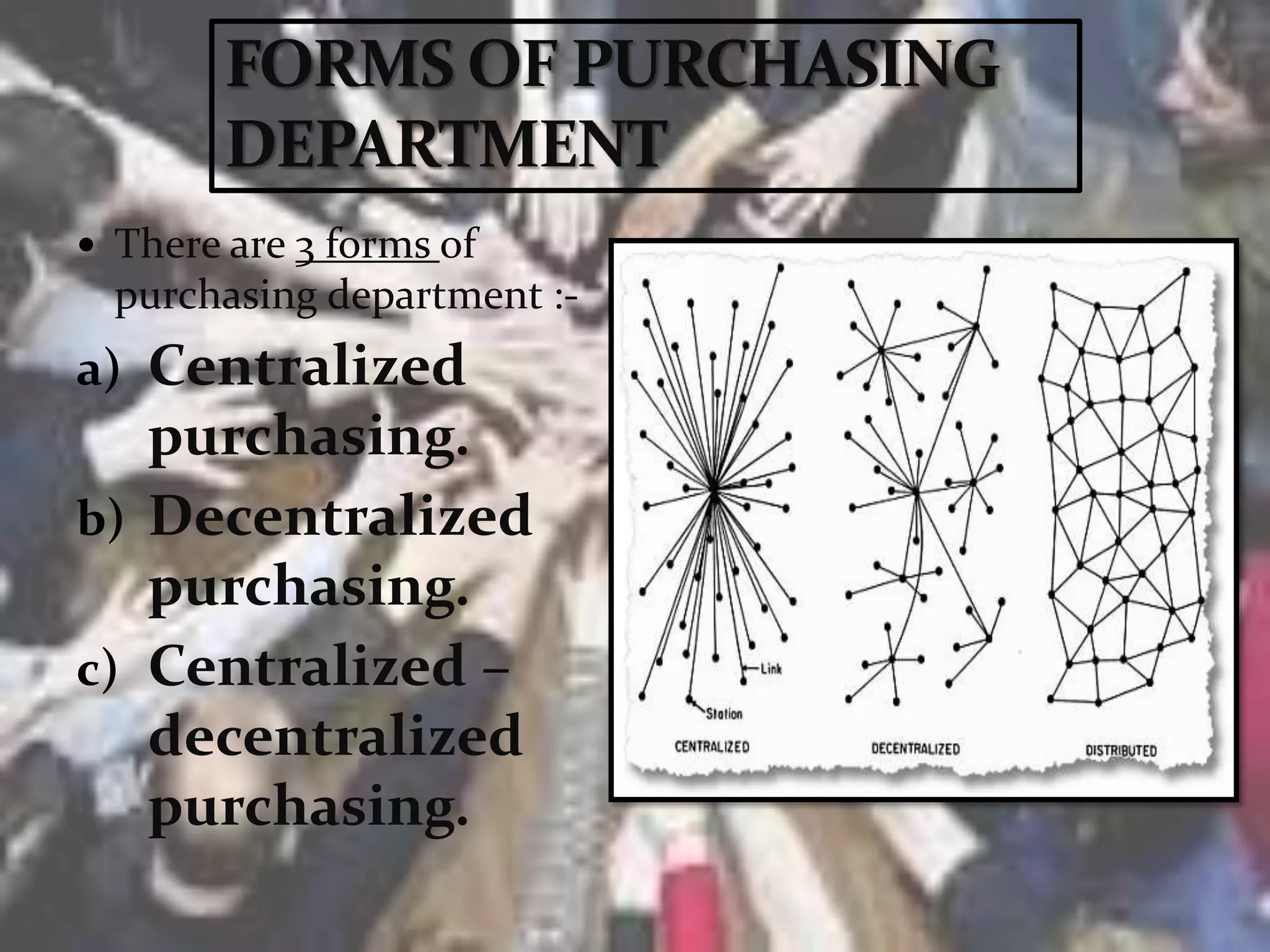

The document discusses the purchasing department and its functions. It notes that the purchasing department is responsible for acquiring necessary materials, minimizing costs, evaluating and approving vendors, tracking orders, and checking invoices. The goal of the purchasing department is to obtain high quality materials at the lowest cost while maintaining good vendor relationships. It also discusses different forms of purchasing departments and the purchasing process.