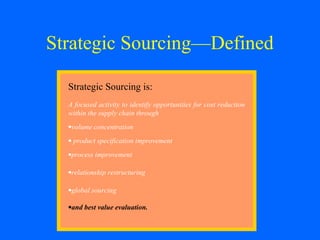

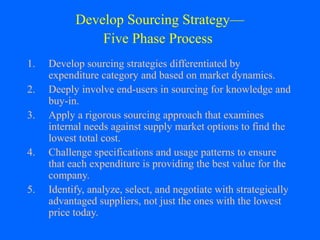

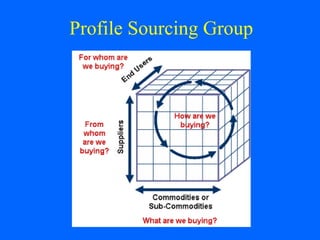

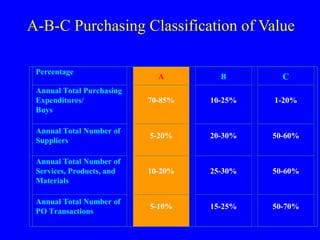

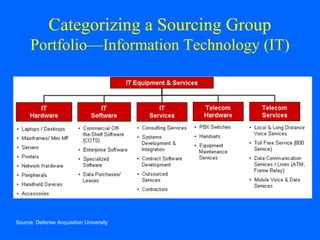

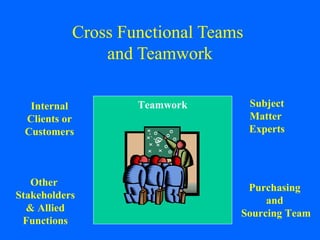

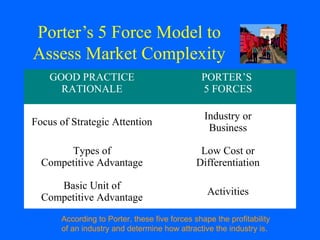

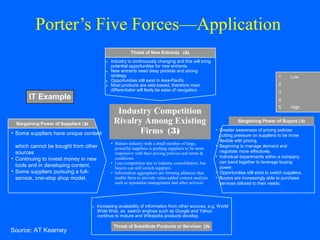

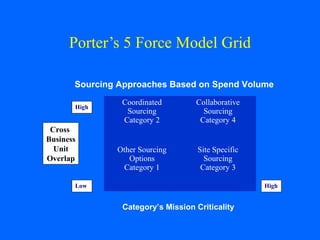

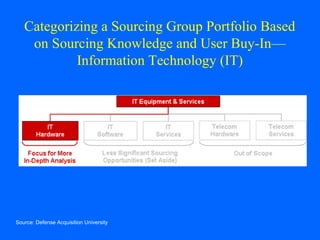

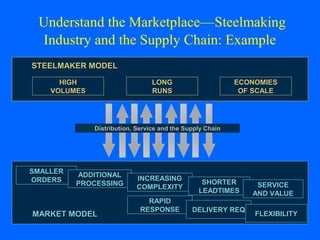

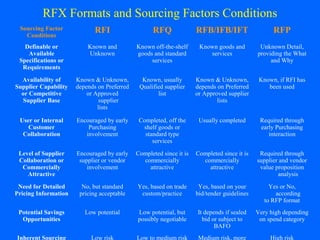

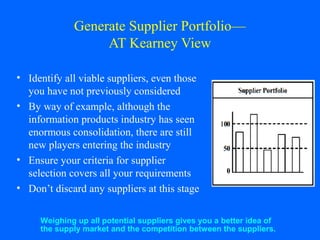

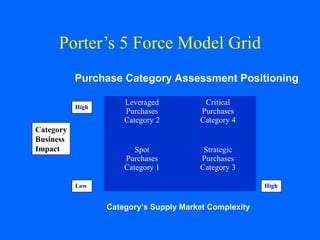

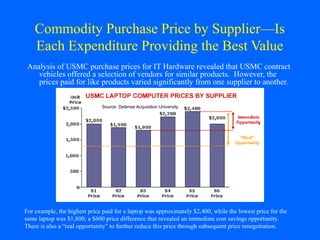

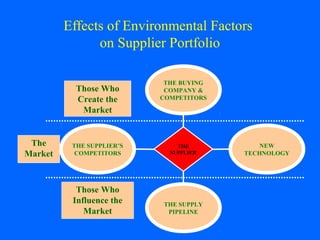

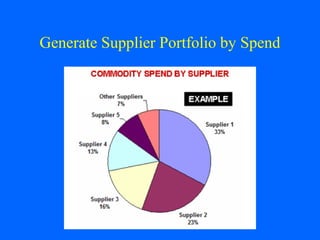

The document outlines a strategic sourcing framework developed by Thomas L. Tanel, detailing a five-phase process aimed at identifying cost reduction opportunities within supply chains. It emphasizes the importance of involving end-users, analyzing market dynamics, and negotiating with strategically advantageous suppliers rather than solely focusing on price. Additionally, the document discusses Porter’s Five Forces model to assess market complexity and the significance of categorizing sourcing portfolios based on purchasing impact and buyer-supplier dynamics.