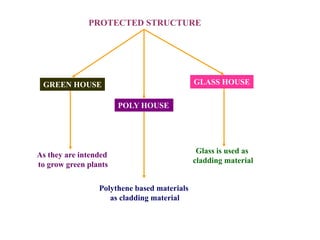

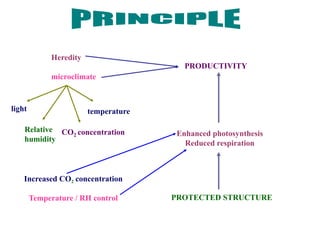

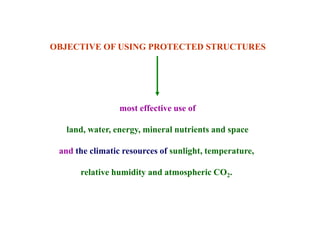

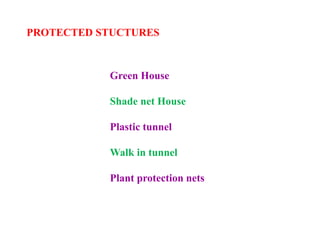

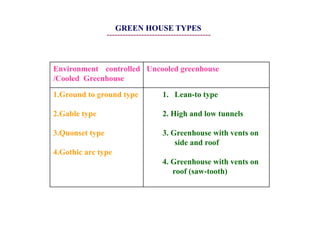

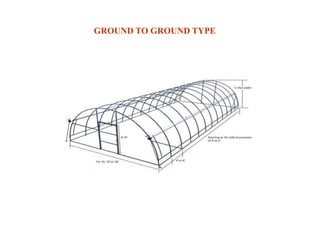

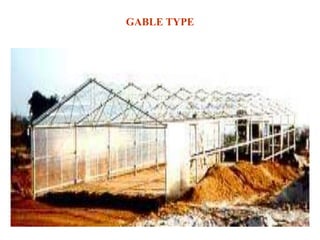

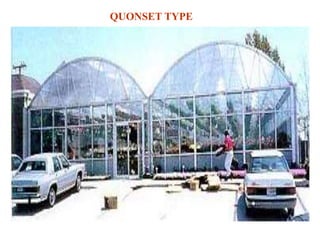

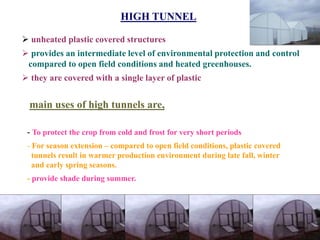

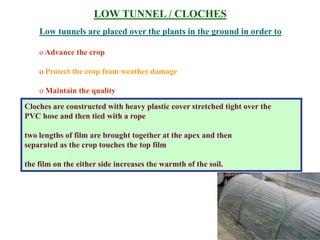

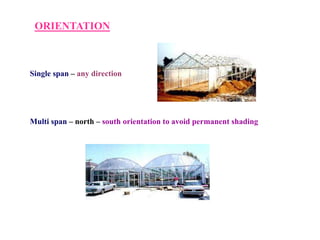

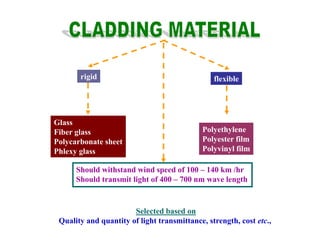

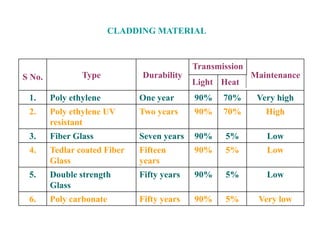

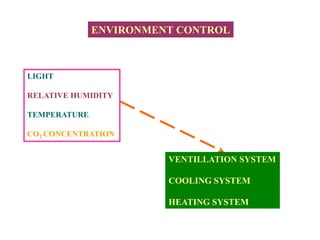

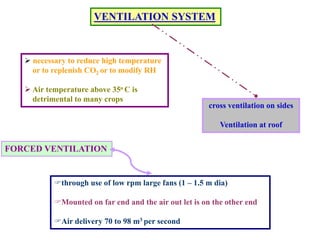

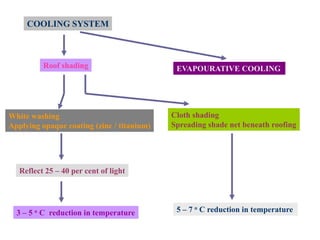

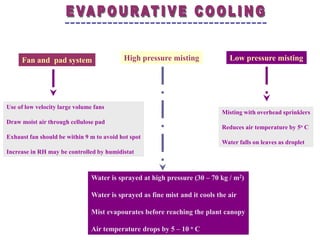

This document discusses protected cultivation, which involves growing plants under controlled environments using protected structures like greenhouses. It describes the advantages of protected cultivation as higher productivity, quality, pest control, and year-round production. The history of protected cultivation is outlined, dating back to Roman times. Modern greenhouses first appeared in Italy and Holland. The document then focuses on the history and development of greenhouses in India. Different types of protected structures are defined, and greenhouse types like ground-to-ground, gable, and quonset are described. Environmental control methods to regulate temperature, humidity, light, and CO2 are also summarized.