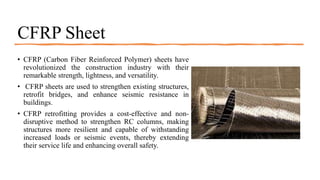

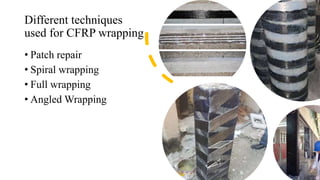

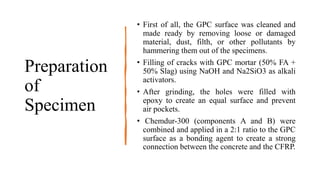

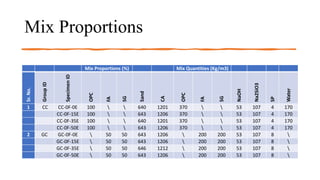

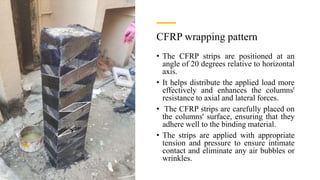

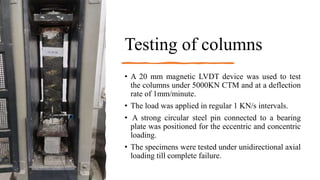

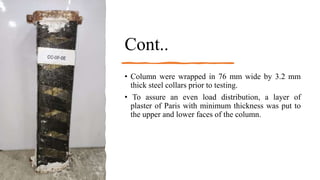

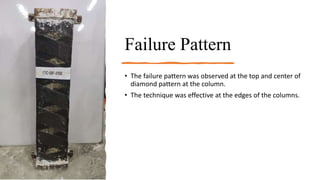

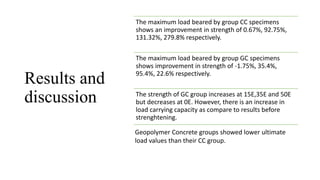

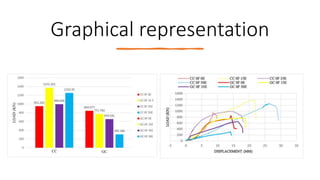

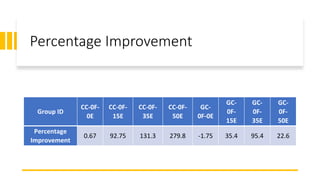

The document discusses the performance of geopolymer concrete structural members retrofitted with carbon fiber reinforced polymer (CFRP) wraps. It describes how test specimens of conventional concrete (CC) and geopolymer concrete (GC) columns were prepared, wrapped with CFRP at varying levels of eccentricity, and tested to failure. The results showed that CFRP wrapping improved the load-carrying capacity of both CC and GC columns, with the highest improvements seen in CC columns wrapped at 50% eccentricity and GC columns wrapped at 35% eccentricity. The conclusions recommend carefully planning CFRP layer orientation based on structural analysis to further increase strength.