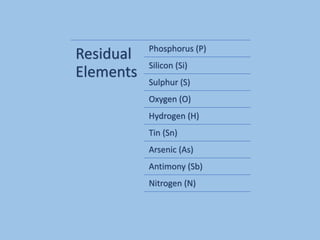

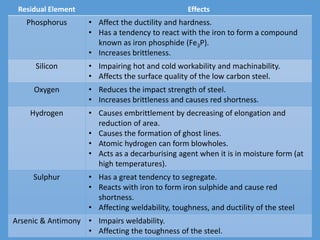

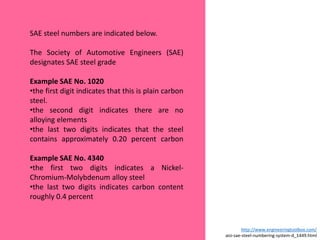

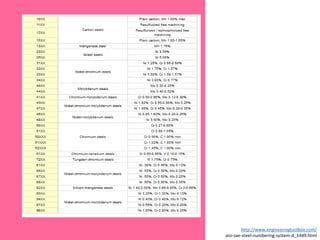

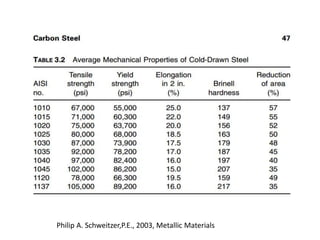

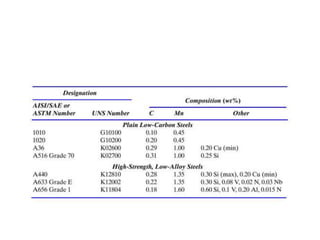

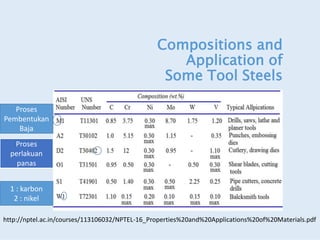

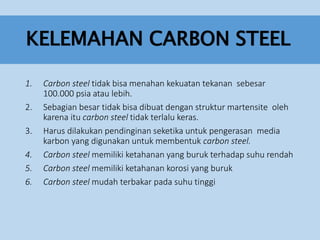

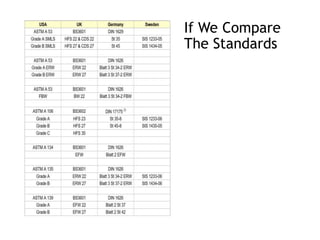

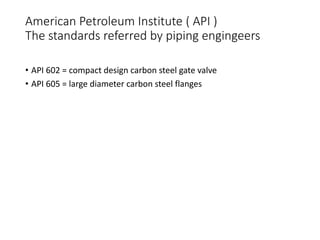

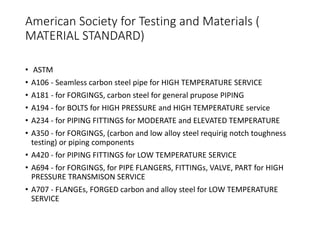

The document discusses carbon steel, including its composition, properties, grades, and applications. Low-carbon steel contains 0.025-0.25% carbon and is inexpensive and easy to machine. Medium-carbon steel has 0.25-0.6% carbon and is stronger, used for tools and machinery. High-carbon steel has 0.6-1.4% carbon, providing high hardness but low ductility, used for tools. Residual elements like phosphorus and sulfur affect properties like ductility and brittleness. Standards like ASME and API specify requirements for carbon steel pipes, flanges, and valves.