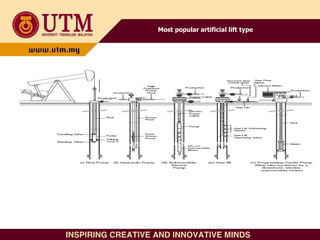

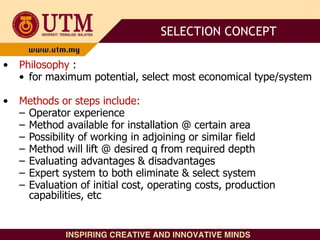

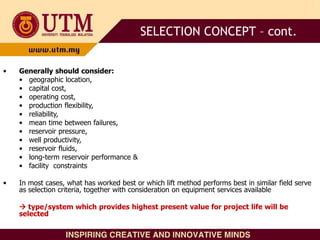

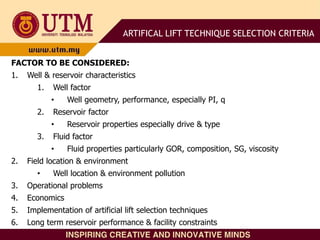

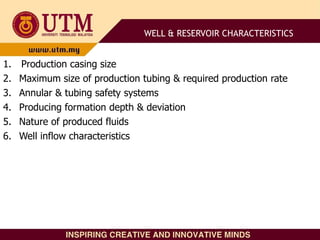

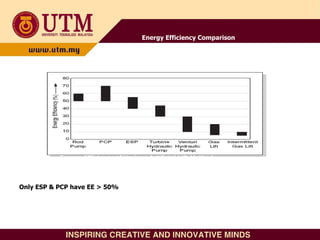

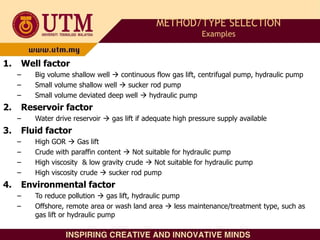

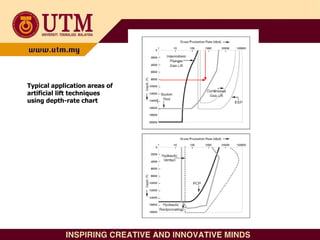

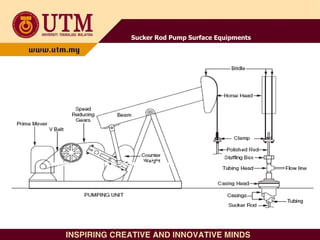

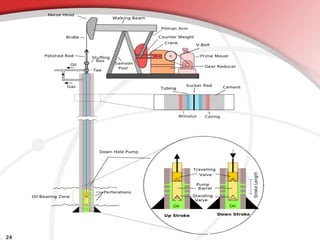

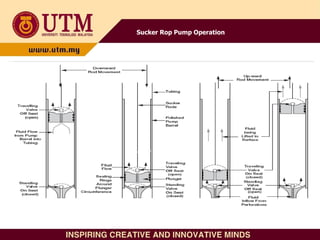

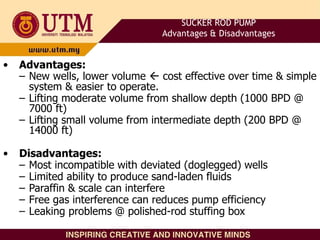

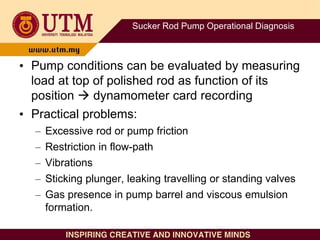

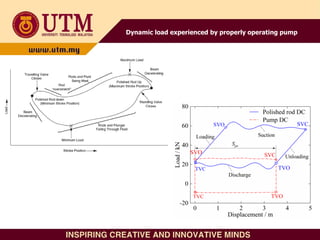

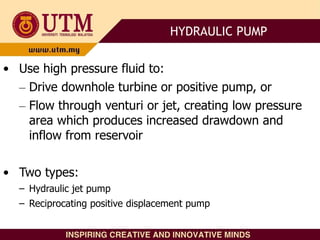

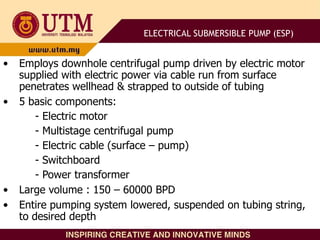

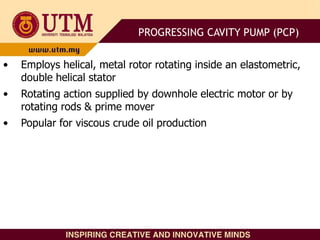

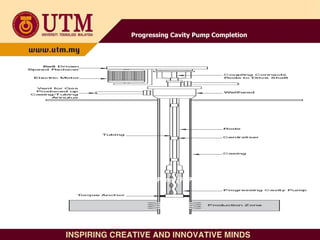

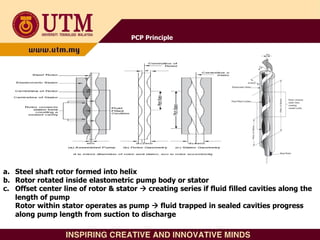

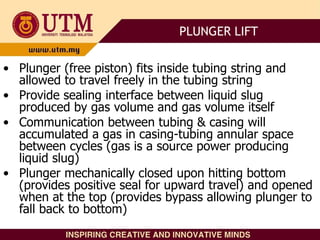

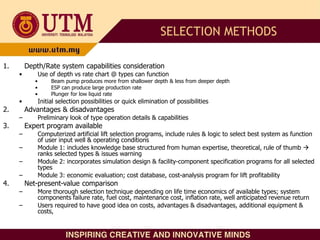

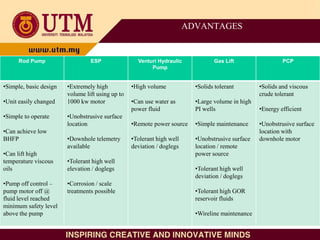

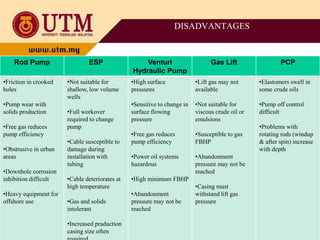

This document discusses artificial lift systems used to assist in lifting fluid from wells when reservoir pressure is insufficient. It covers the main types of artificial lift systems including sucker rod pumps, progressing cavity pumps, hydraulic pumps, electrical submersible pumps, gas lift, and plunger lift. Key factors in selecting the appropriate system include well characteristics, reservoir properties, fluid properties, field location, economics, and long-term reservoir performance. Sucker rod pumps, the most widely used system, are described in more detail.