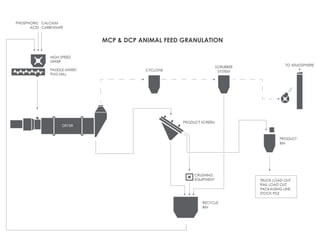

The document outlines the importance of phosphates in animal feeds, highlighting their role in promoting health in plants and animals. It describes the processing of phosphate rock into phosphoric acid and the production of monocalcium and dicalcium phosphate through a modernized granulation technique. The Feeco approach, involving a high-speed mixer, enhances the quality and uniformity of the resulting animal feed products compared to traditional methods.