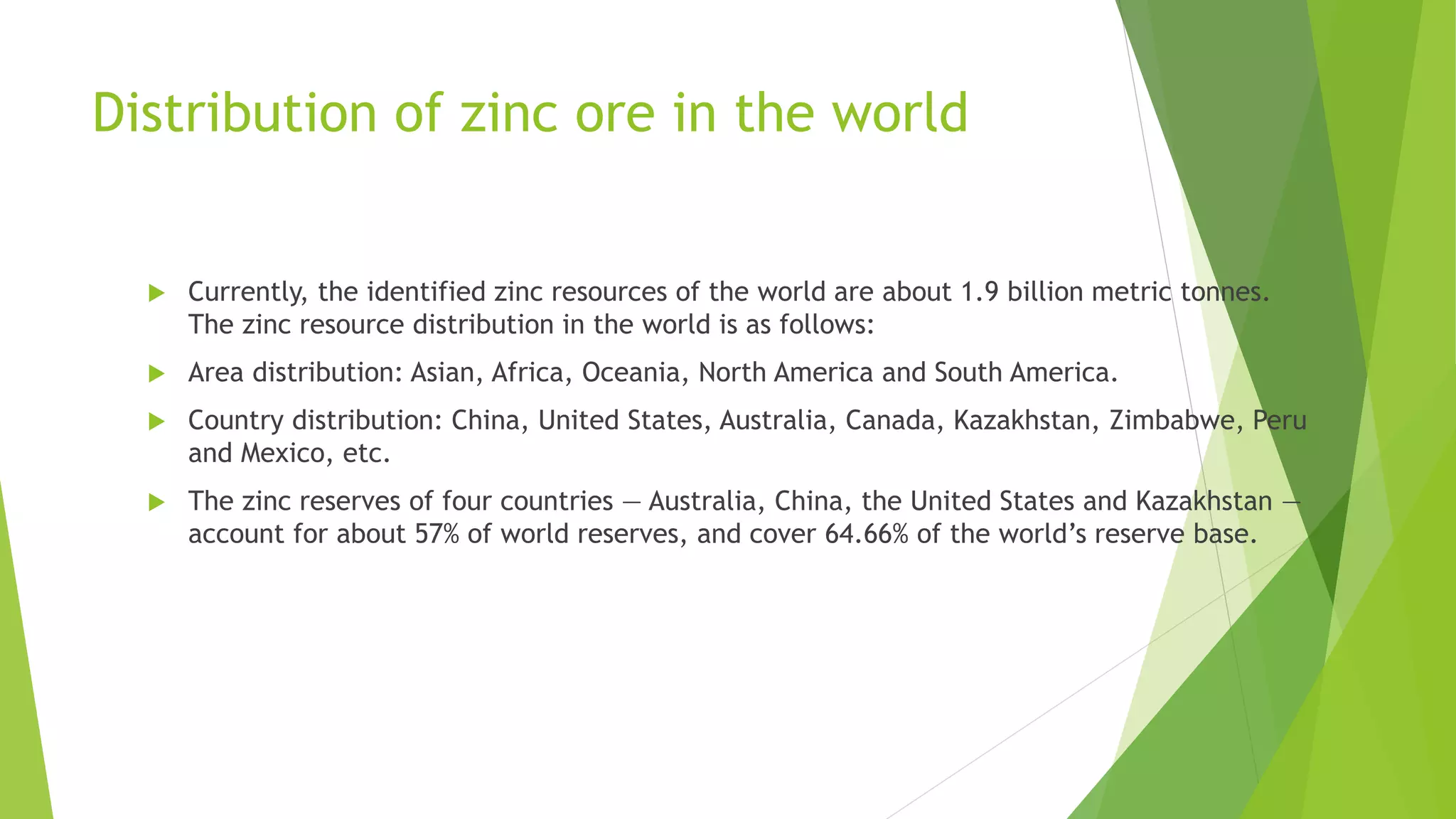

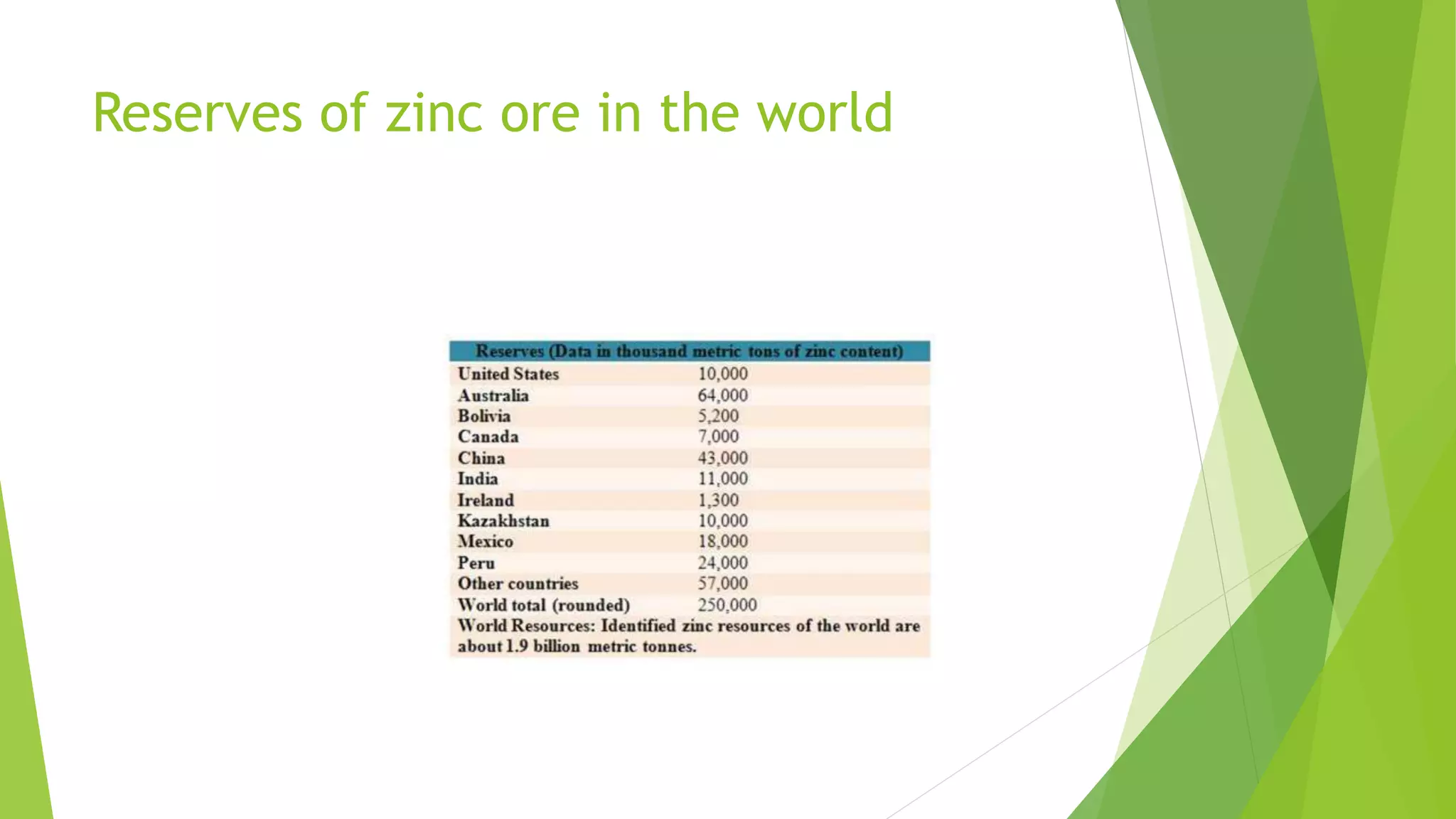

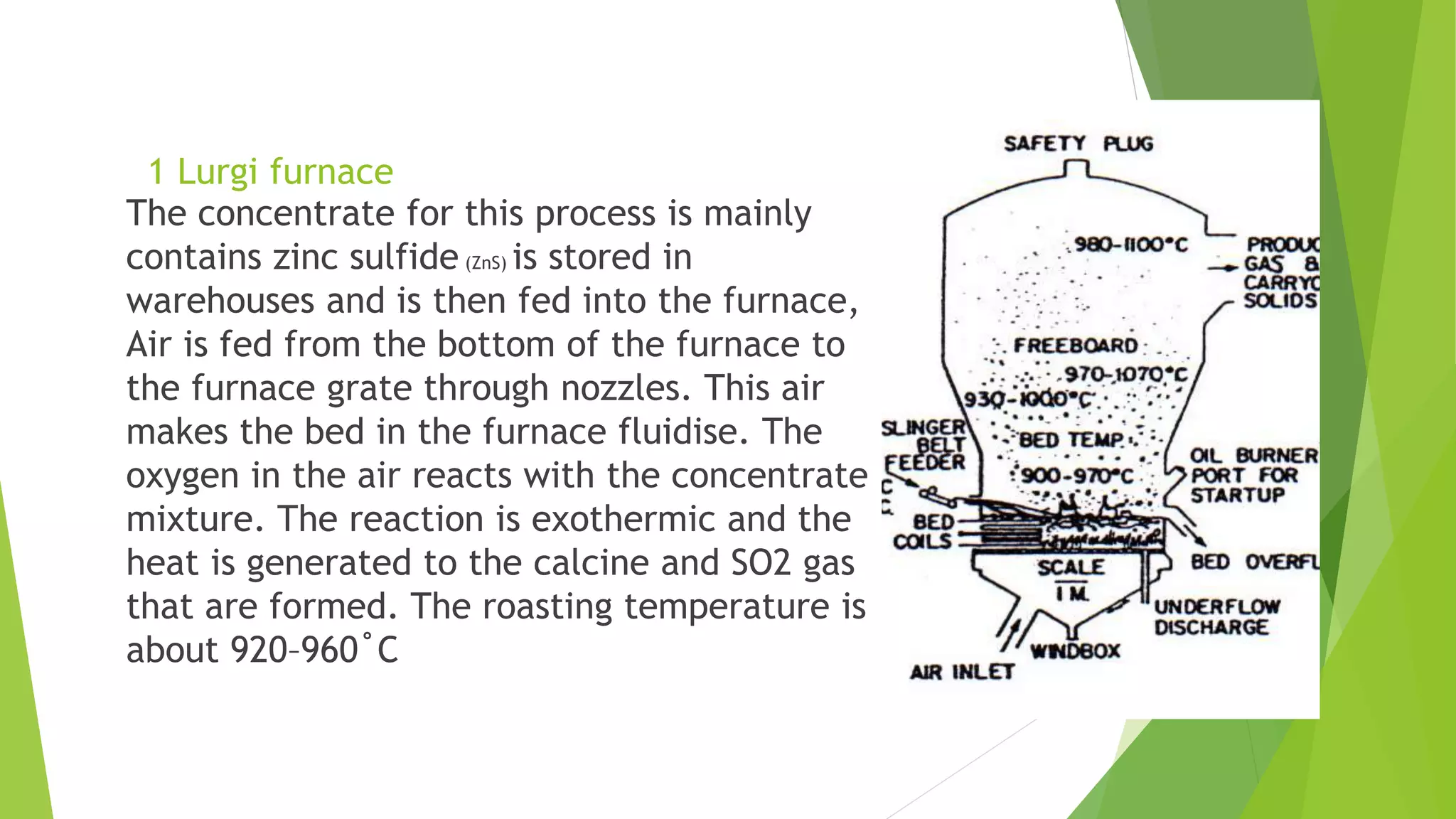

The document details the extraction of zinc through pyrometallurgical processes, highlighting its properties, common ores, and the methods of extraction including roasting and smelting. Key zinc minerals like sphalerite and smithsonite are discussed, along with the major global zinc reserves found primarily in North America and Australia. The document also explains the different roasting techniques and the process for producing zinc from ores, which includes steps like calcination and thermal smelting.

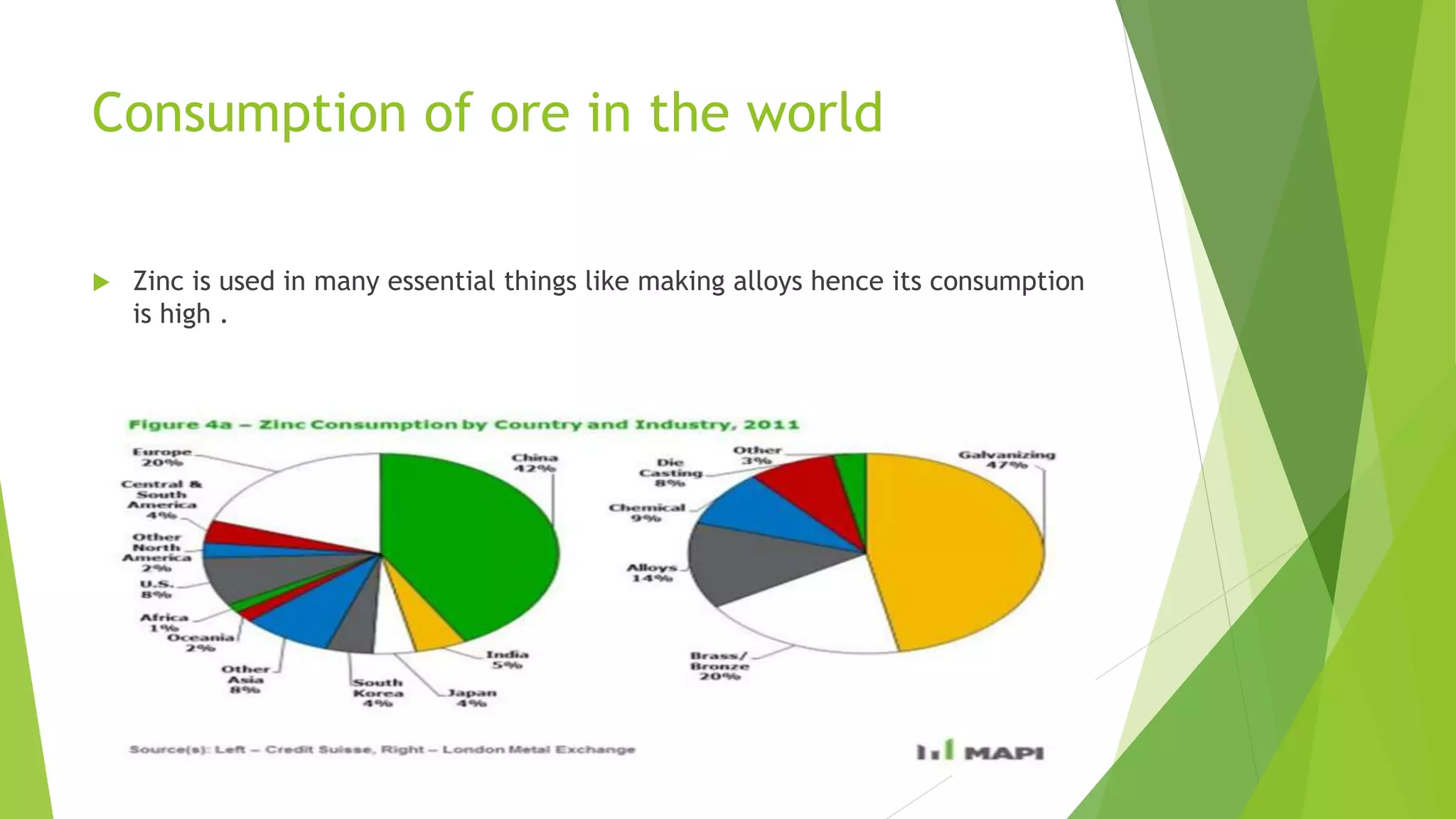

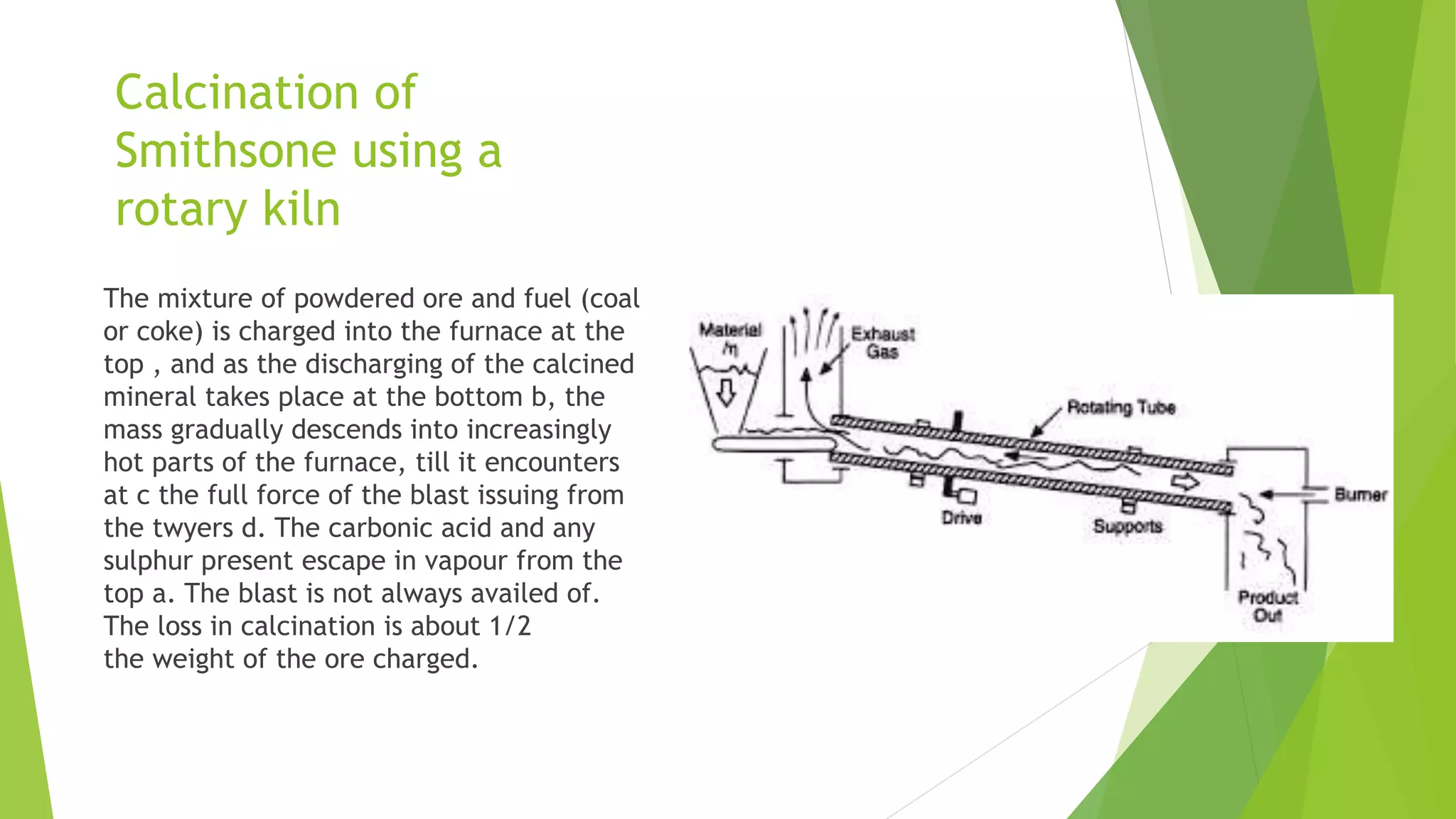

![Zinc ores

Zinc ores are widely distributed throughout the world, although more than 40

percent of the world’s output originates in North America and Australia. The

common zinc-containing minerals are the zinc sulfide known as zinc blende or

sphalerite (ZnS), a ferrous form of zinc blende known as marmatite [(ZnFe)S],

and a zinc carbonate known as calamine or smithsonite (ZnCO3).

The geology of zinc deposits is complex. In most cases, hydrothermal

mechanisms have occurred in which aqueous solutions were forced through

porous strata at high temperatures and pressures to dissolve zinc,](https://image.slidesharecdn.com/extractionofzincpresentation-181121113946/75/Pyrometallurgy-Extraction-of-zinc-presentation-4-2048.jpg)