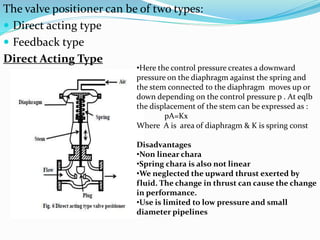

The document discusses batch and continuous manufacturing processes. It defines batch processes as those that operate on discrete quantities of materials in a non-continuous manner, with periods of inactivity between batches. Continuous processes receive and process raw materials into finished units in an uninterrupted flow. Batch processes are useful for small volumes of specialty chemicals and allow scheduling maintenance between batches, while continuous processes are better for large volumes and bulk chemicals with fewer startups/shutdowns. The document also discusses controlling temperature and pressure in batch processes, as well as controlling fluid flow and storage vessel levels in continuous processes. Valve positioners are described as a way to reduce hysteresis in control valves and improve response time.