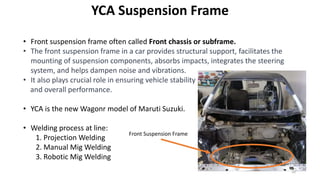

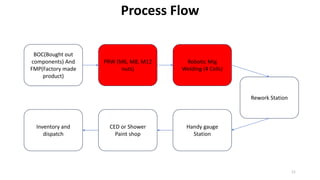

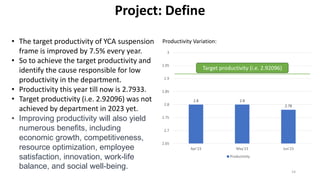

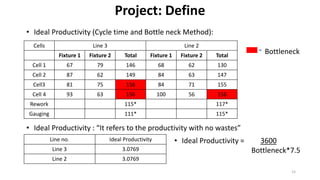

The document summarizes an internship project conducted by Shreyansh Jhanwar at SKH Metals Limited to improve productivity in the YCA suspension frame line. Key points:

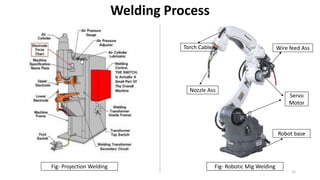

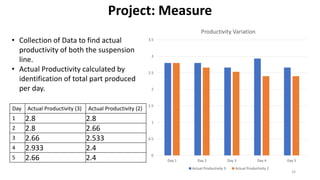

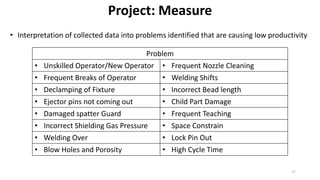

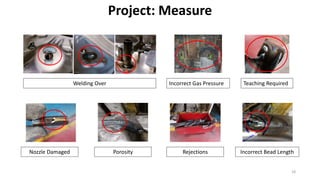

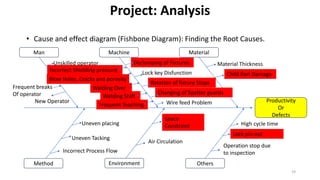

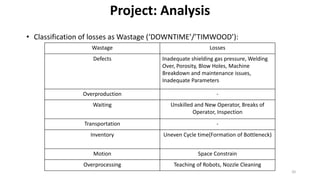

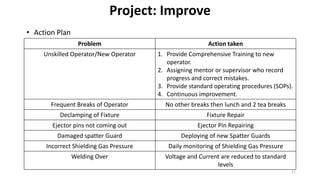

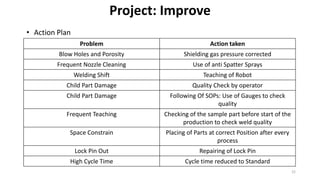

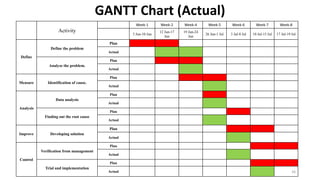

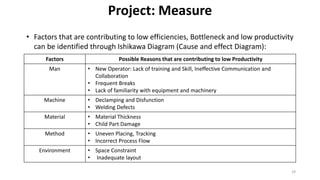

1) Data was collected on current productivity levels which were below targets. Root causes of low productivity like operator issues, equipment issues and process defects were identified using analysis tools.

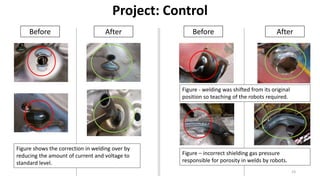

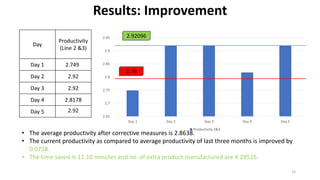

2) Corrective actions like operator training, equipment repairs, process standardization were implemented. Verification showed productivity improved by 7.38% with time savings of 11 minutes per day.

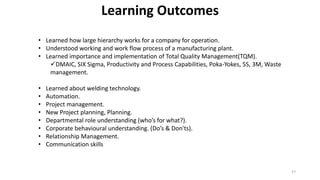

3) The internship helped gain experience in manufacturing processes, quality management tools, project management and relationship building which provided valuable learning outcomes.