This document provides an overview of process auditing in the automobile industry. It highlights the importance of having:

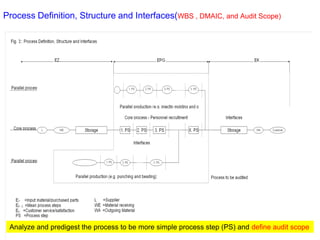

1) A holistic view of the overall organization structure and understanding processes, inputs, and outputs.

2) Using tools like SIPOC, COPs, 6M1E, 5W2H, and 5Whys to analyze and simplify individual process steps and define the audit scope.

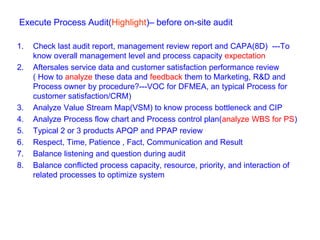

3) Executing an on-site audit by reviewing past reports, data, value stream maps, process flows, and product documentation to understand performance and identify bottlenecks.