The VDA recommends its members adopt the VDA 6.3 (2010) standard for implementing and maintaining quality management systems to meet higher product expectations and ensure robust processes throughout the manufacturing and supply chain. The VDA 6.3 process audit focuses on verifying organizational performance rather than mere conformance to standards, assessing process risks, responsibilities, and communication to improve effectiveness. It breaks down the product life cycle into seven audit elements and emphasizes ongoing process improvement, particularly for supplier management and customer satisfaction.

![Kiran Walimbe

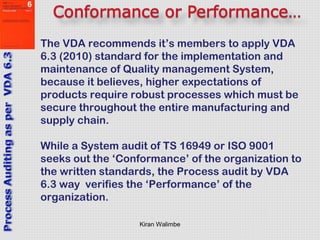

Classification Overall level of

achievement Eg

[%]

Description of the

classification

A Eg > or = 90 Quality capable

B 80 = or < Eg < 90 Conditionally

quality capable

C Eg < 80 Not quality

capable

At the end of this audit the audited organization may

get one of the following ratings.](https://image.slidesharecdn.com/processauditingaspervda6-150220040706-conversion-gate02/85/Process-auditing-as-per-VDA-6-3-13-320.jpg)