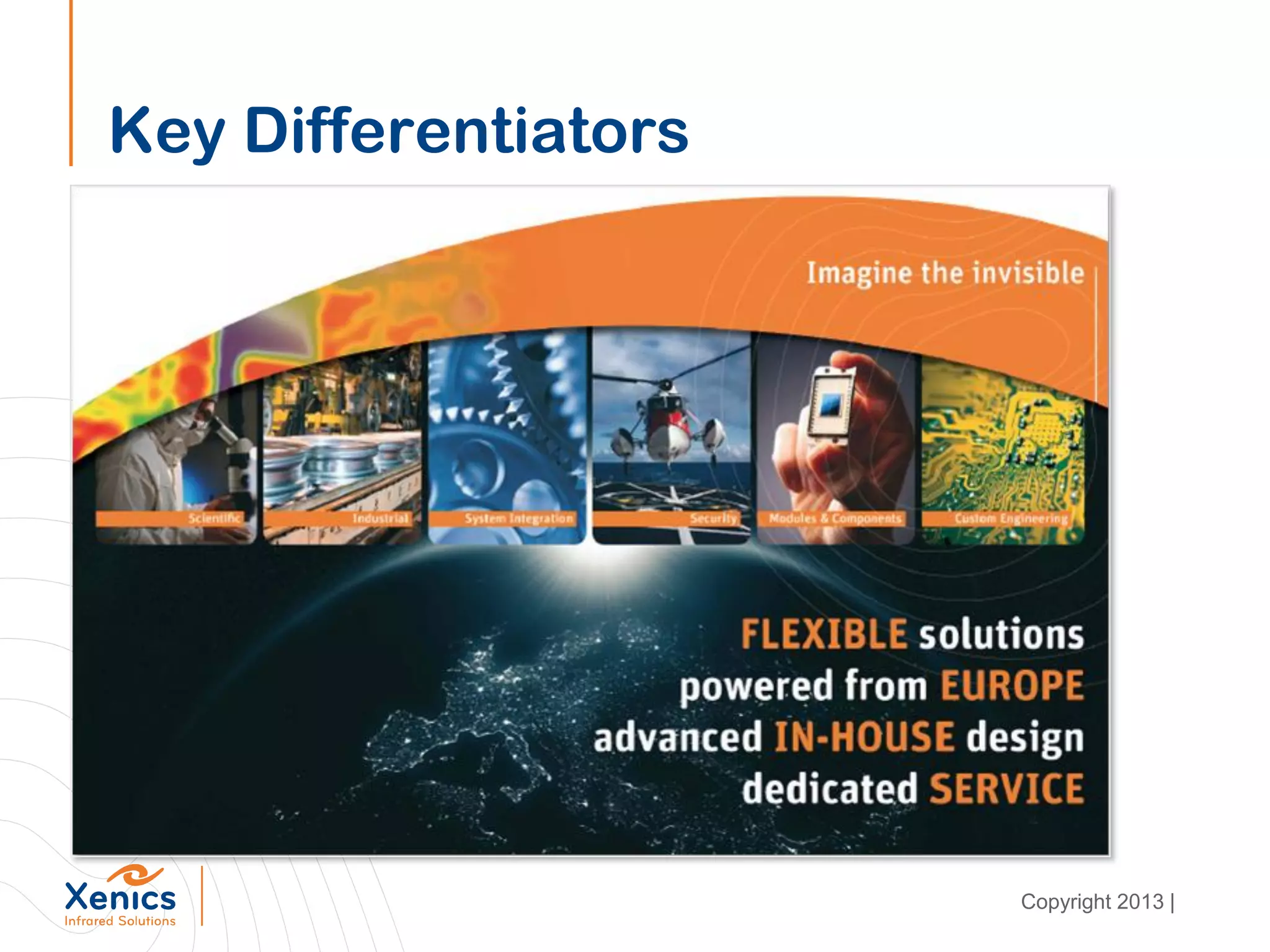

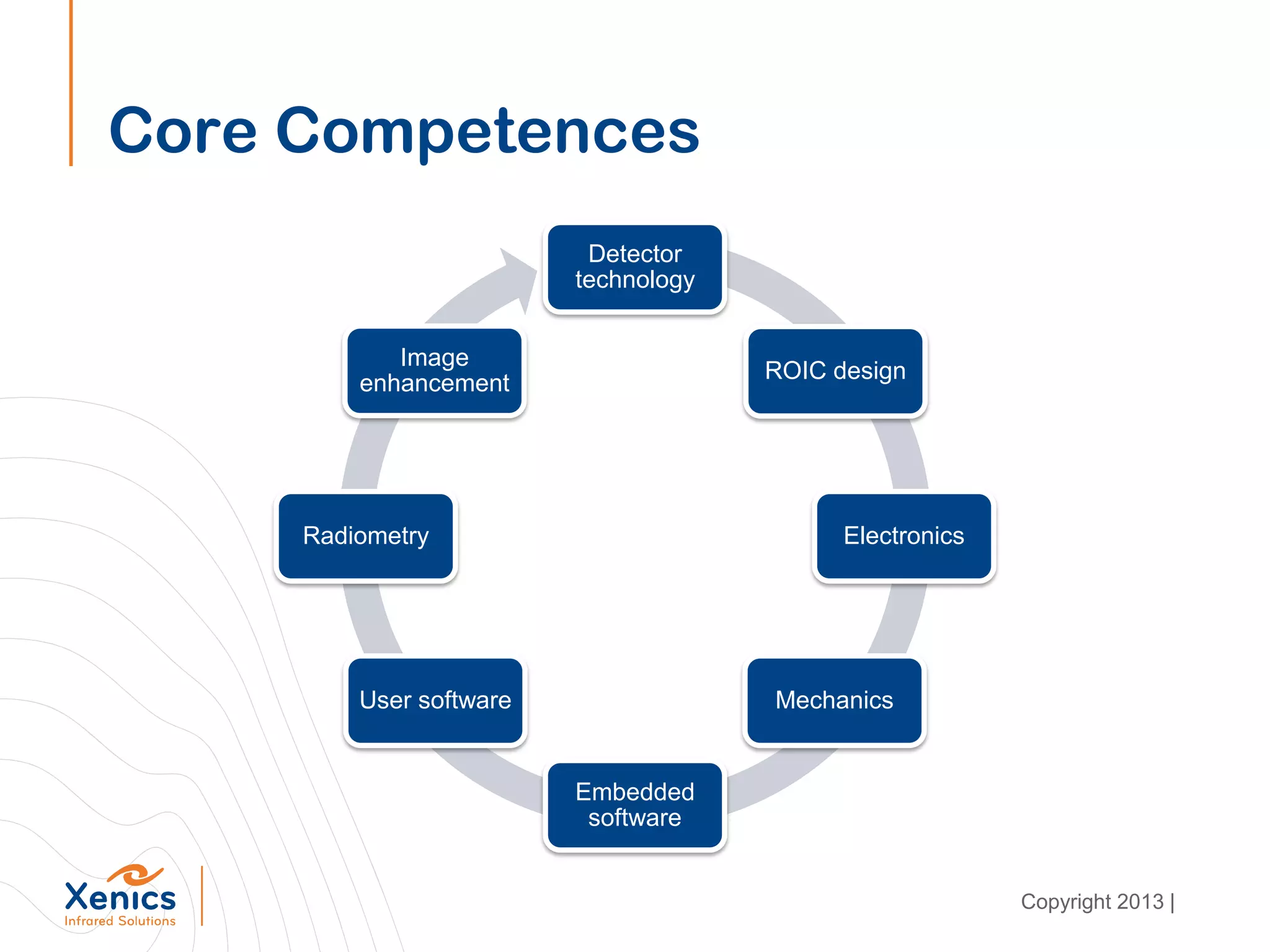

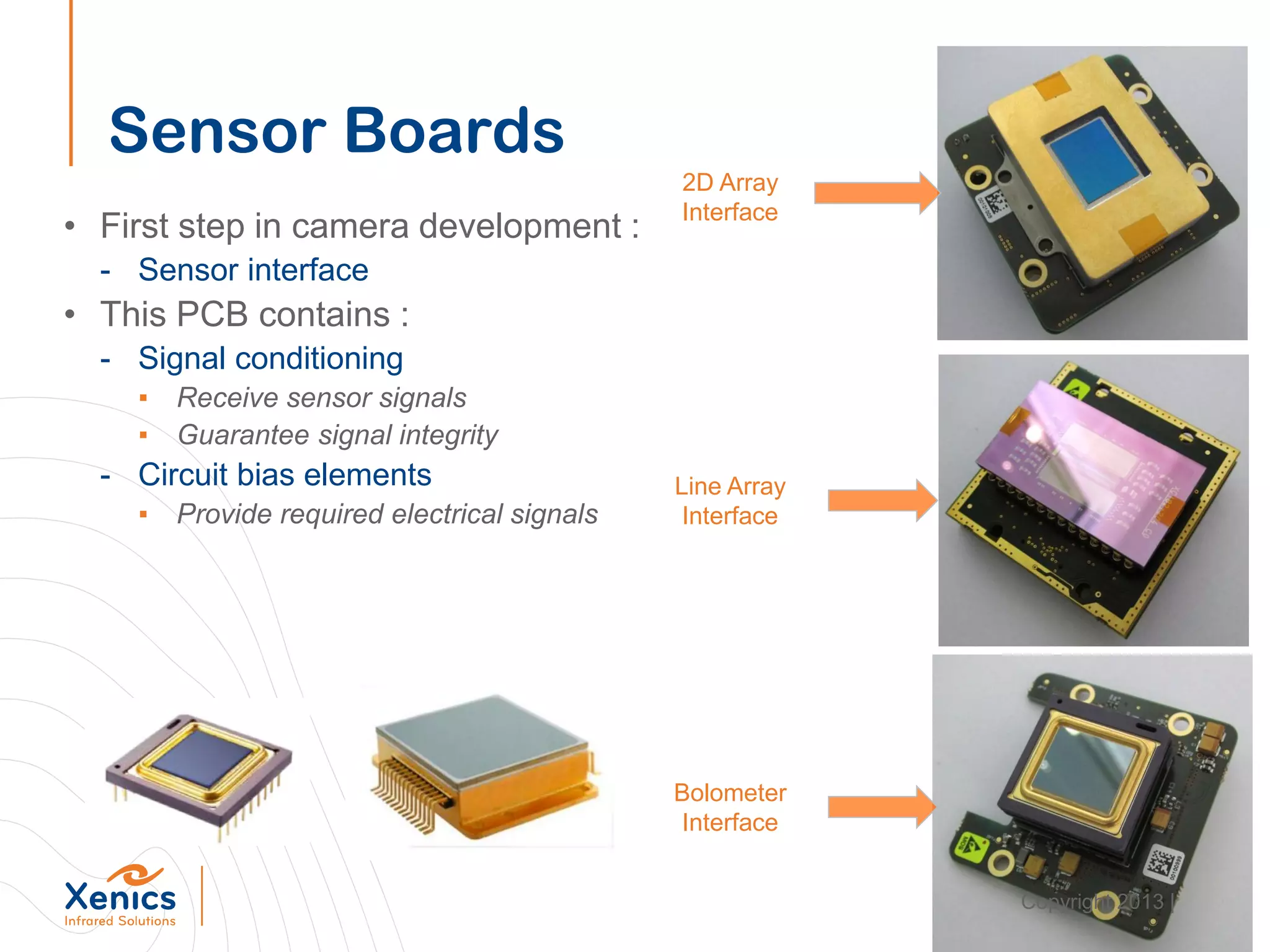

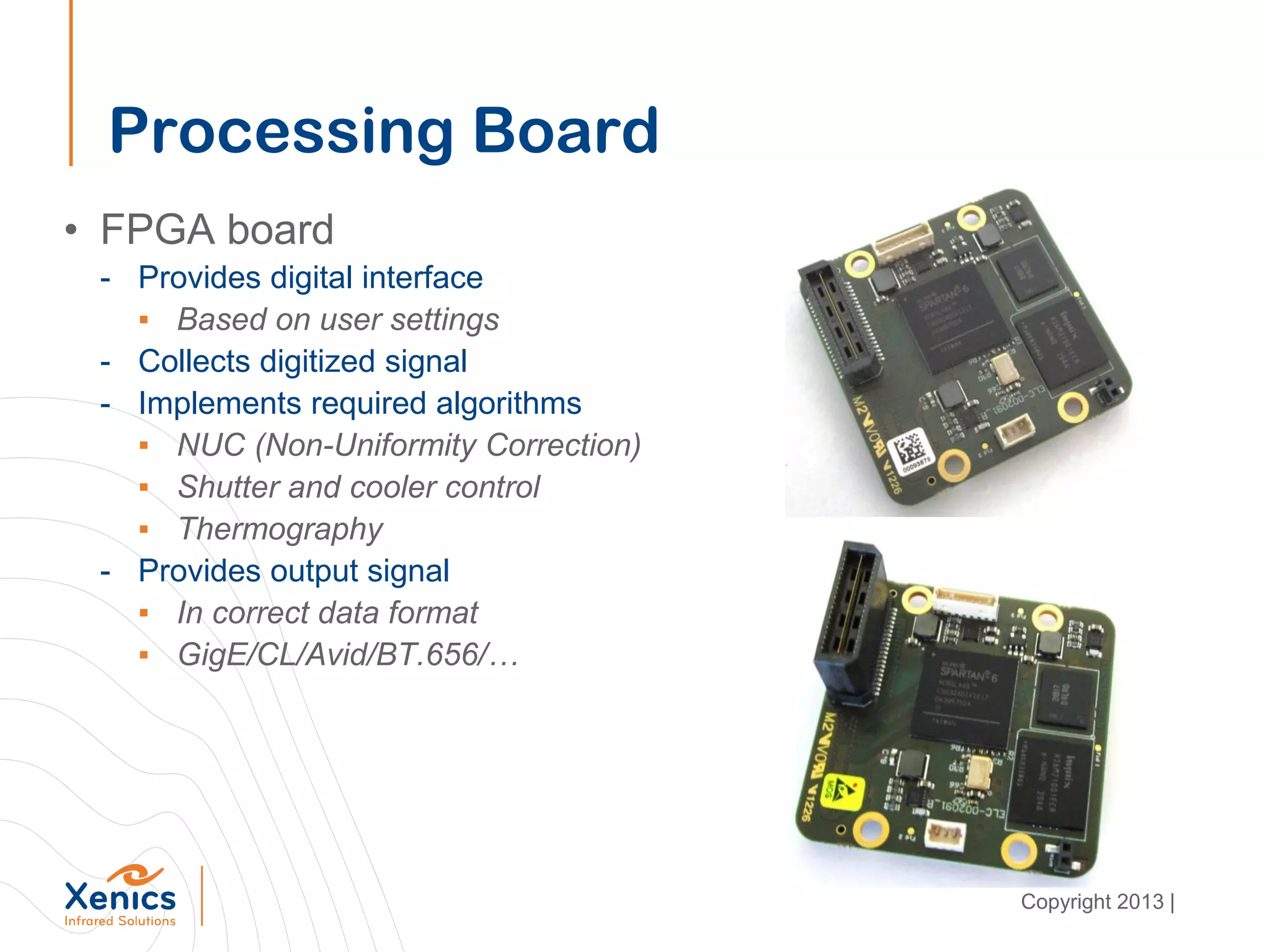

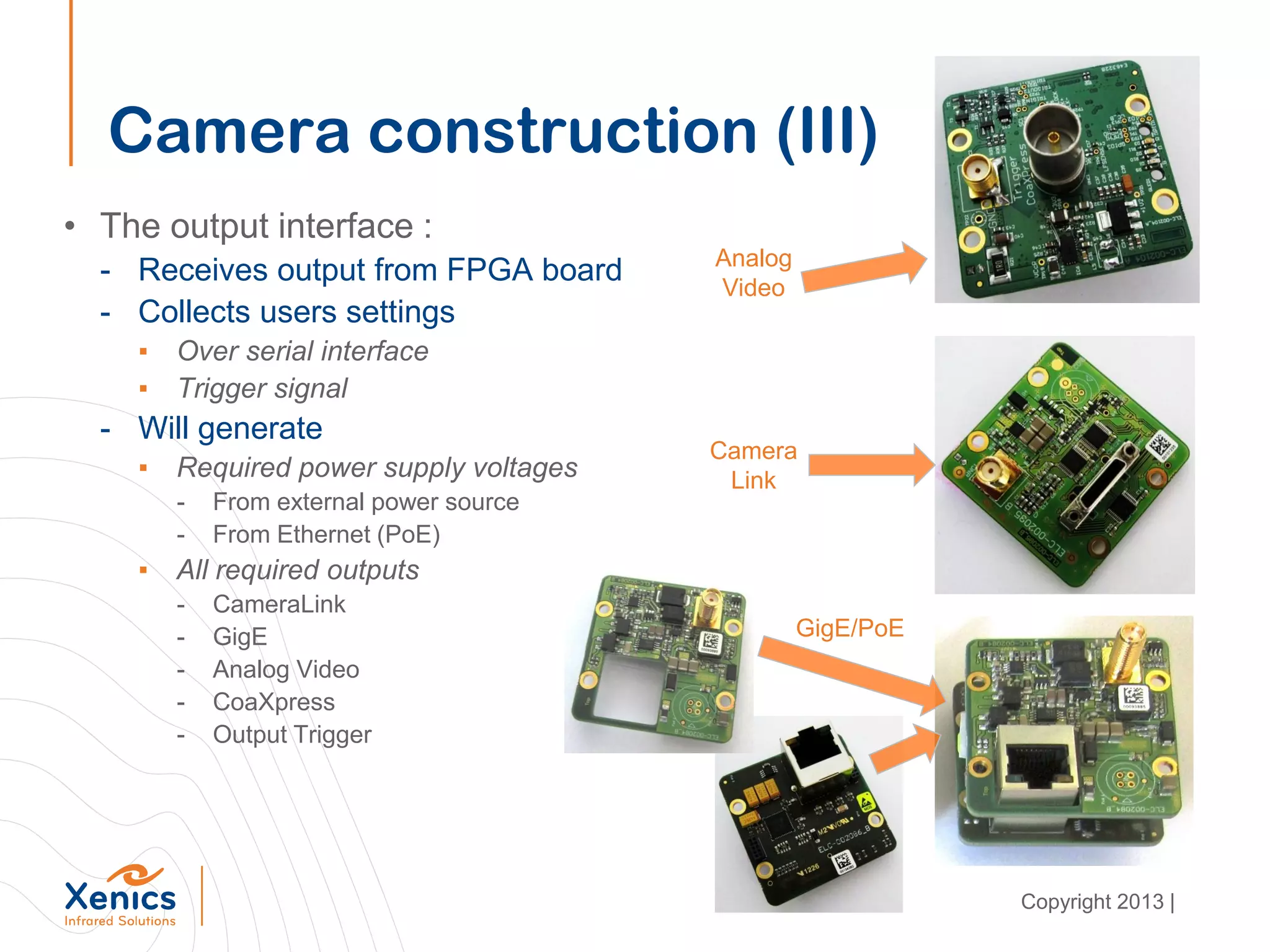

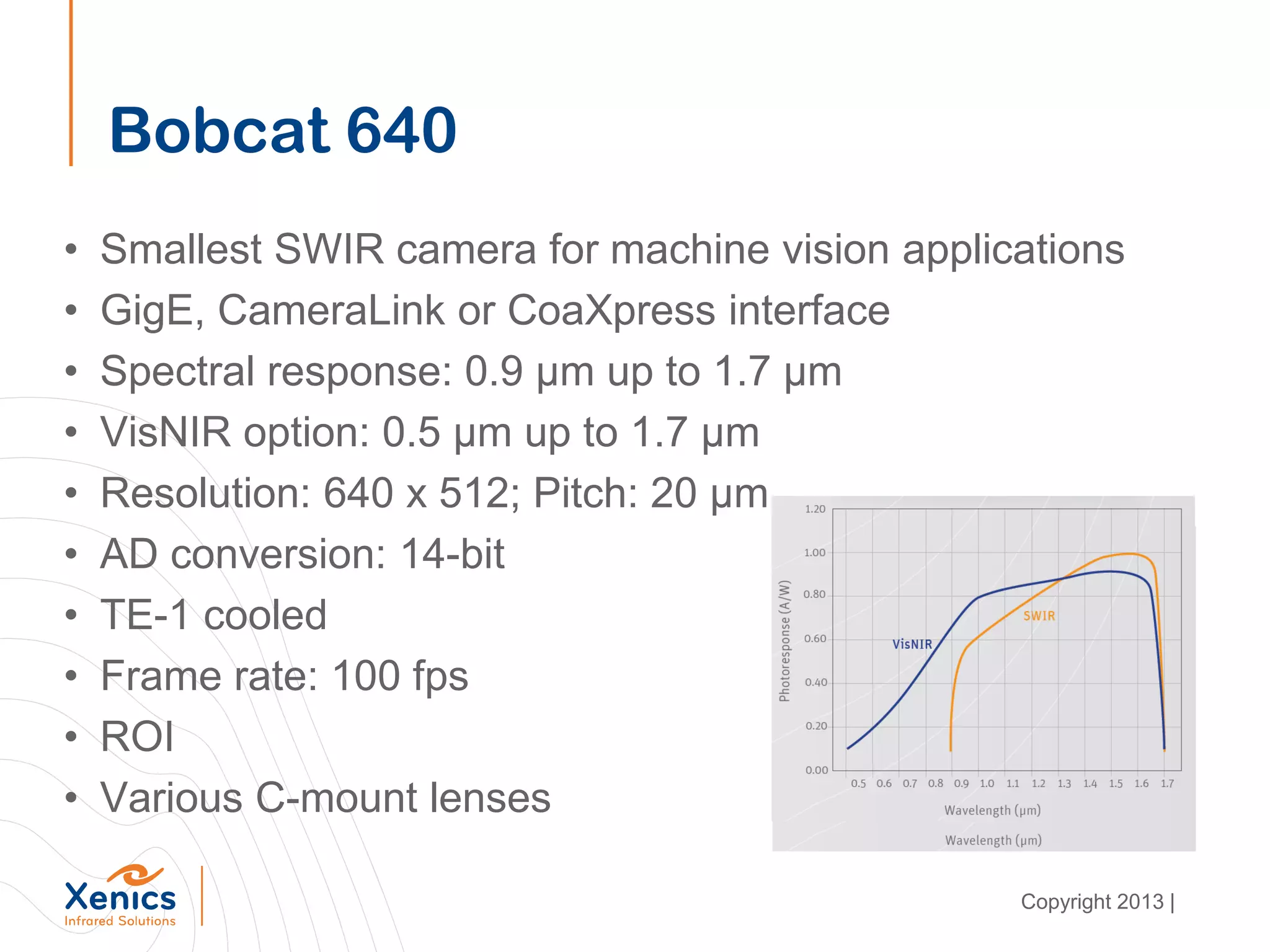

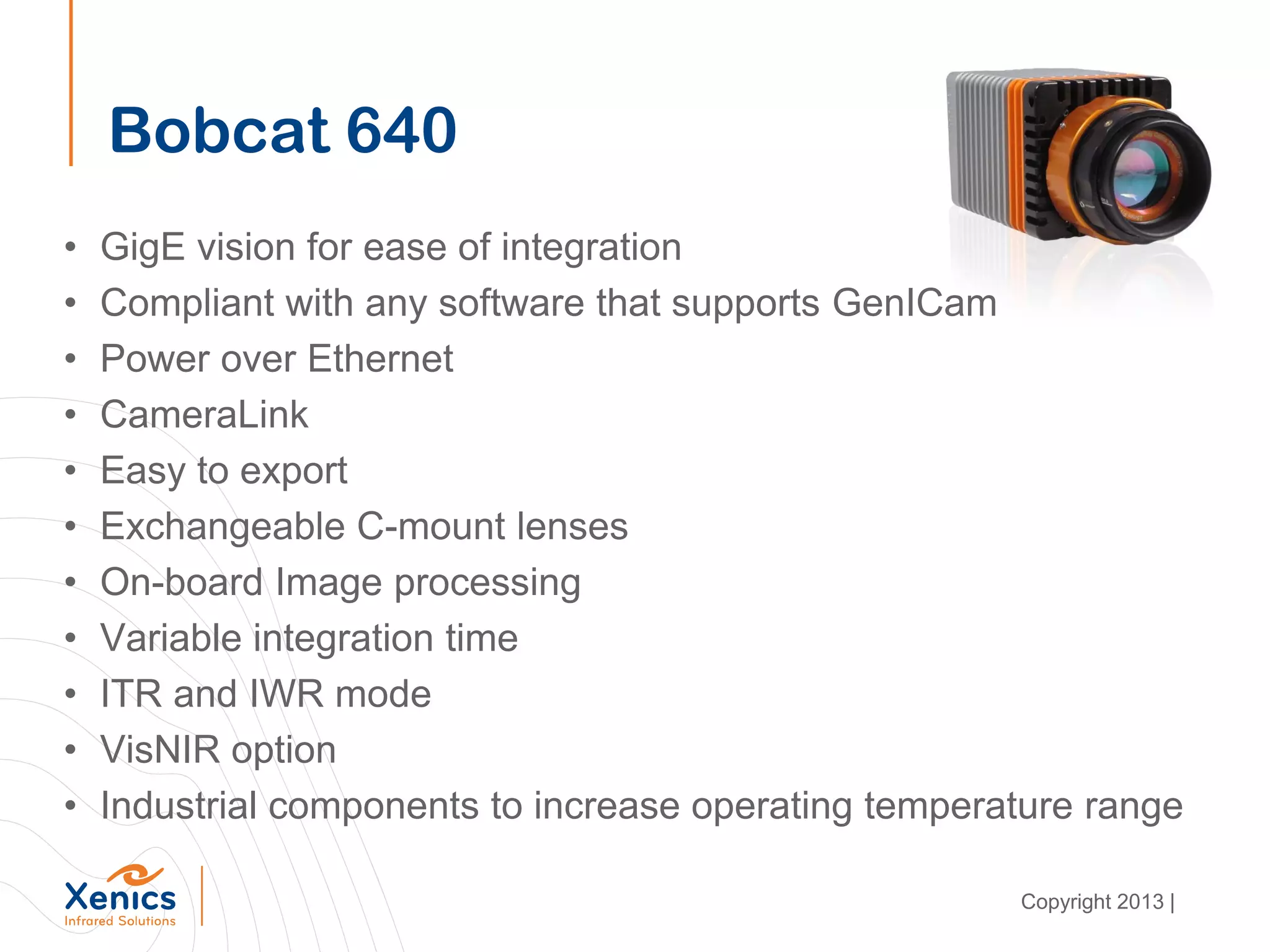

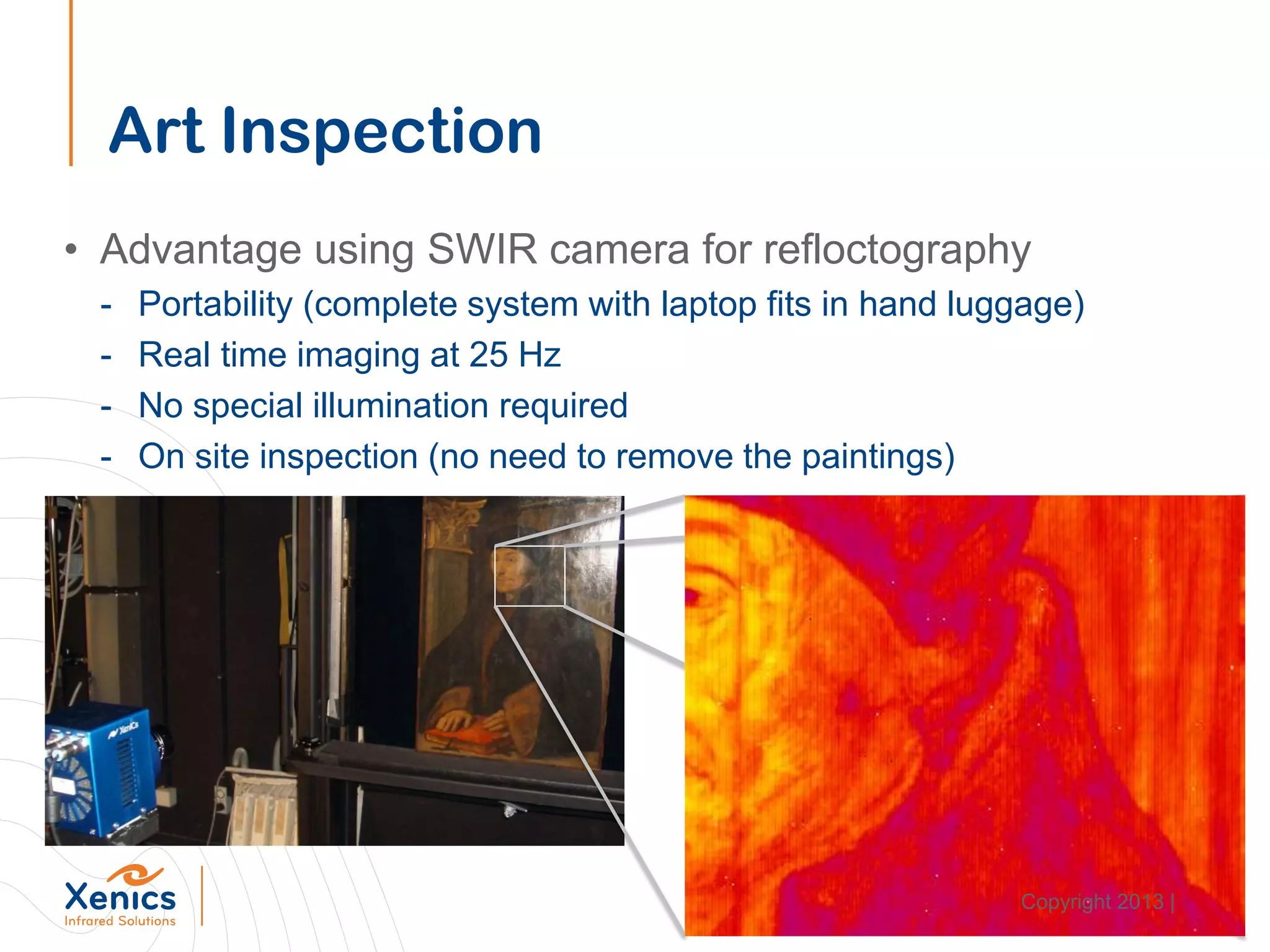

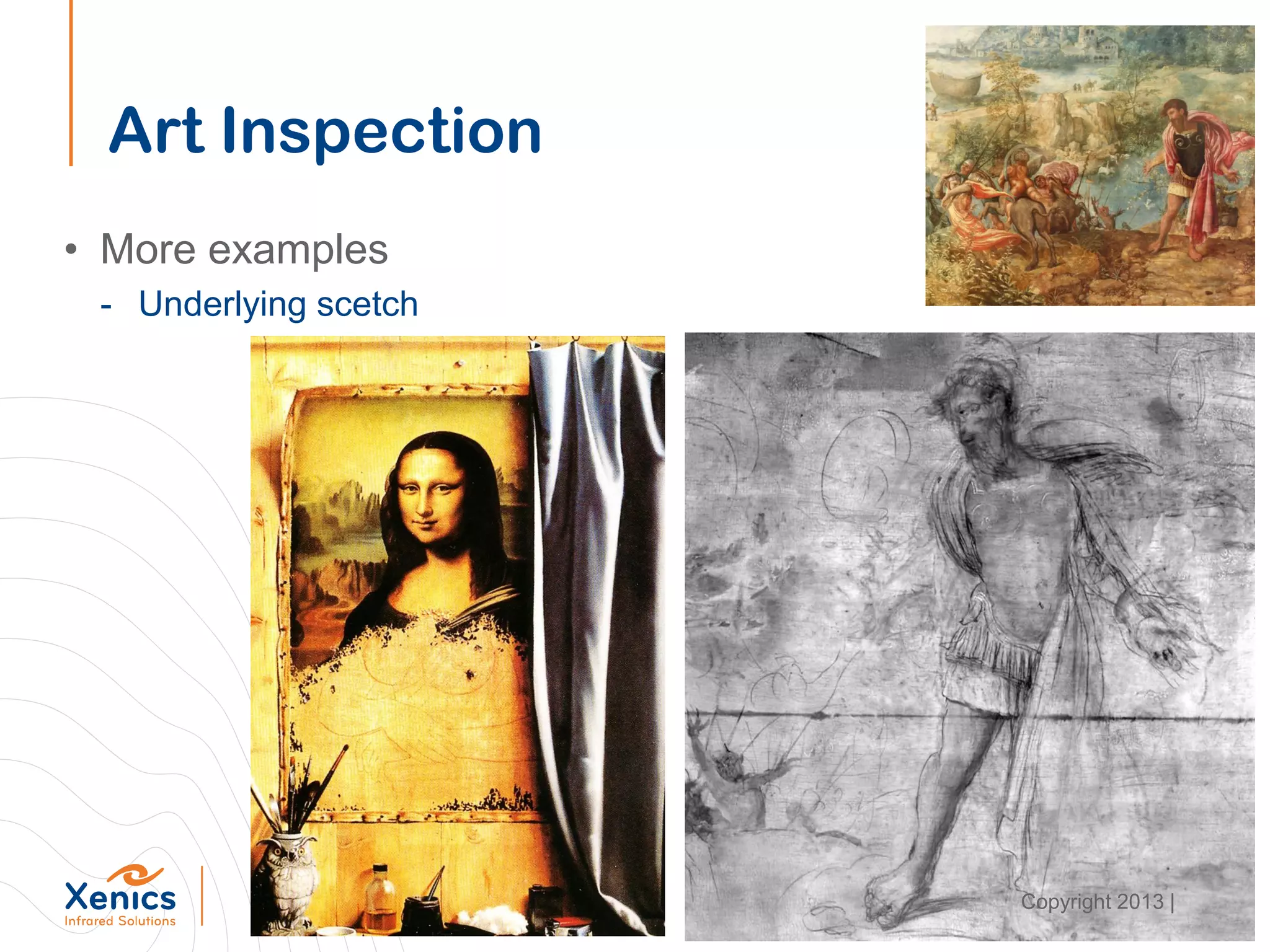

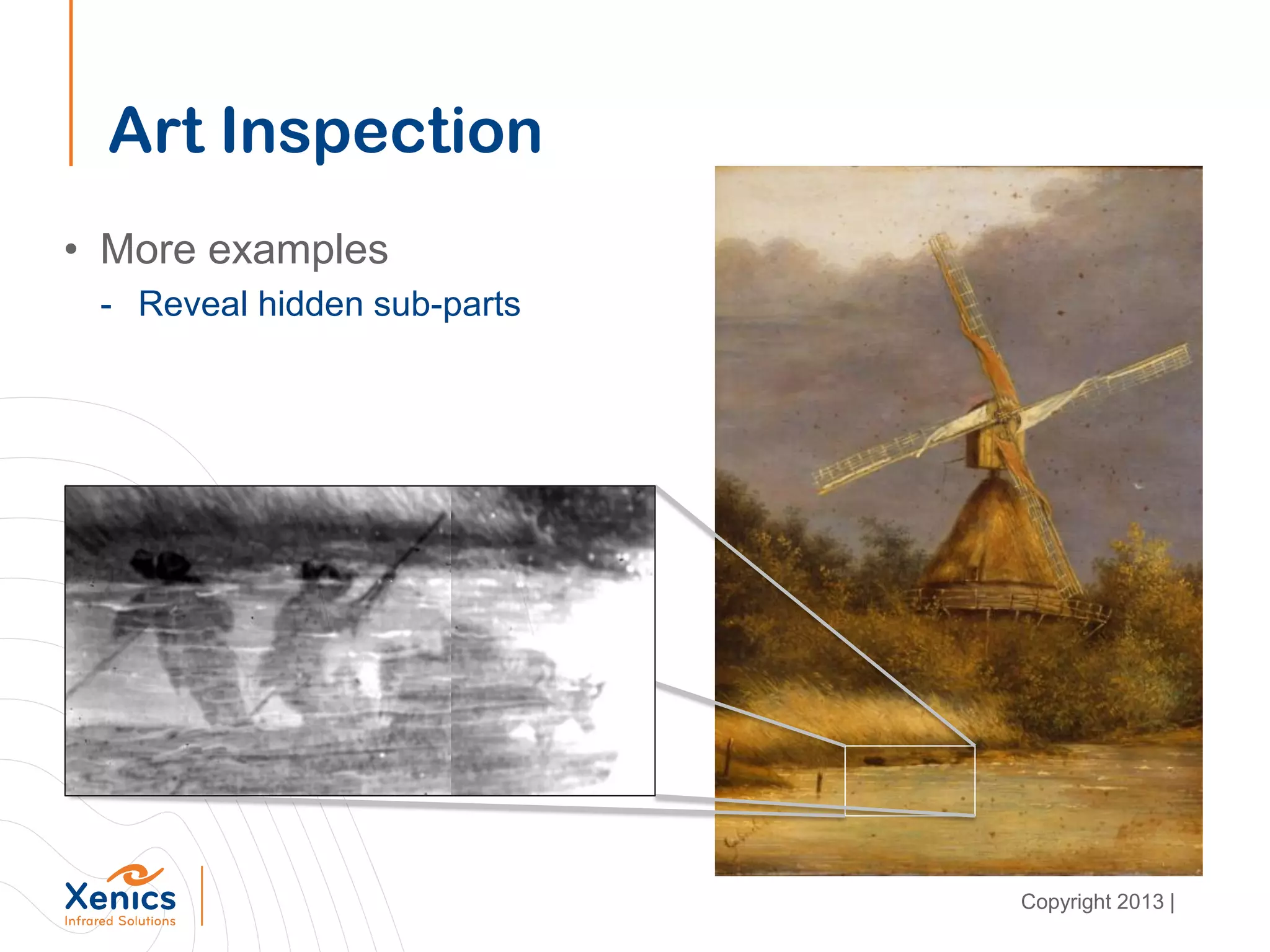

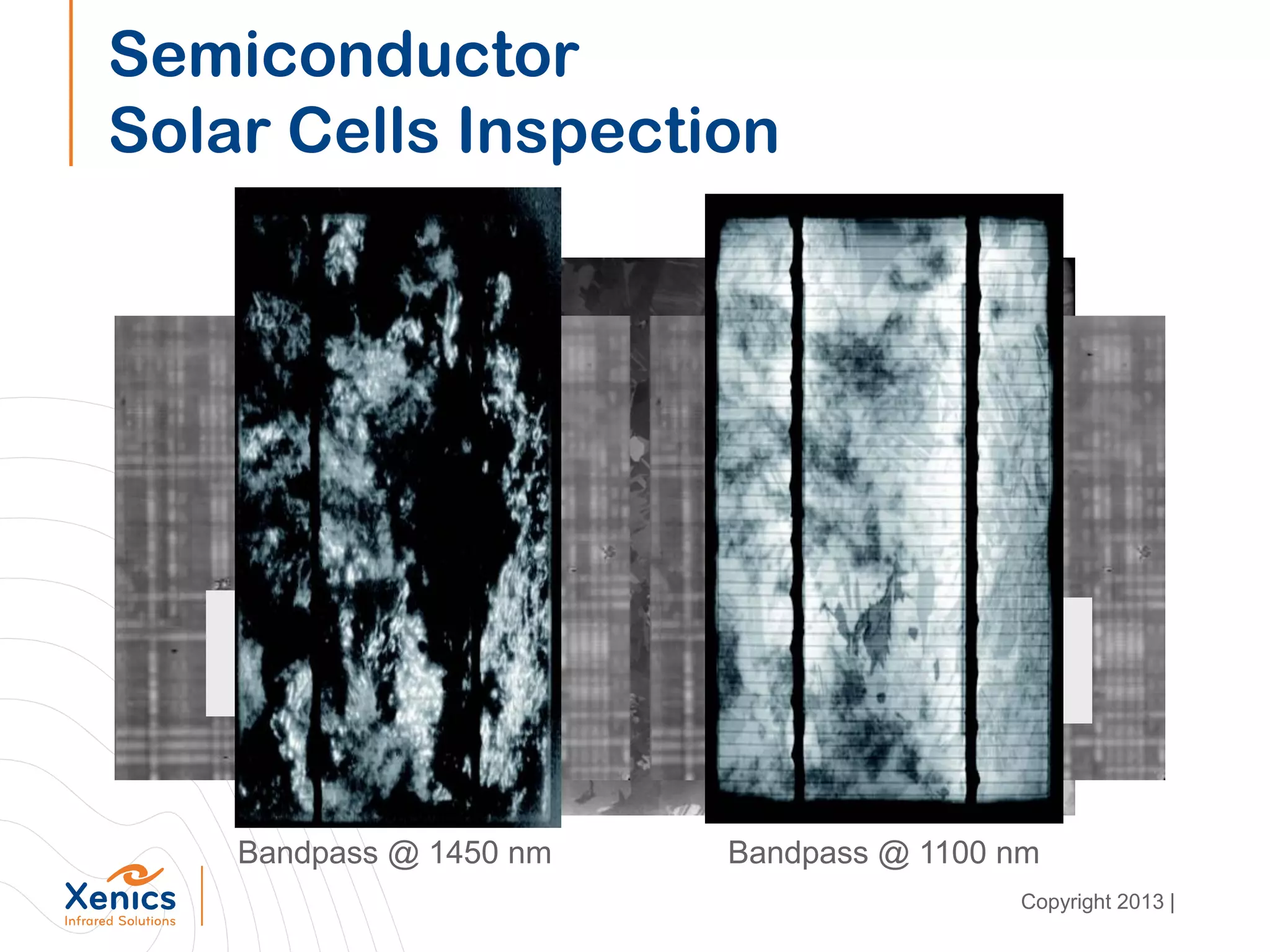

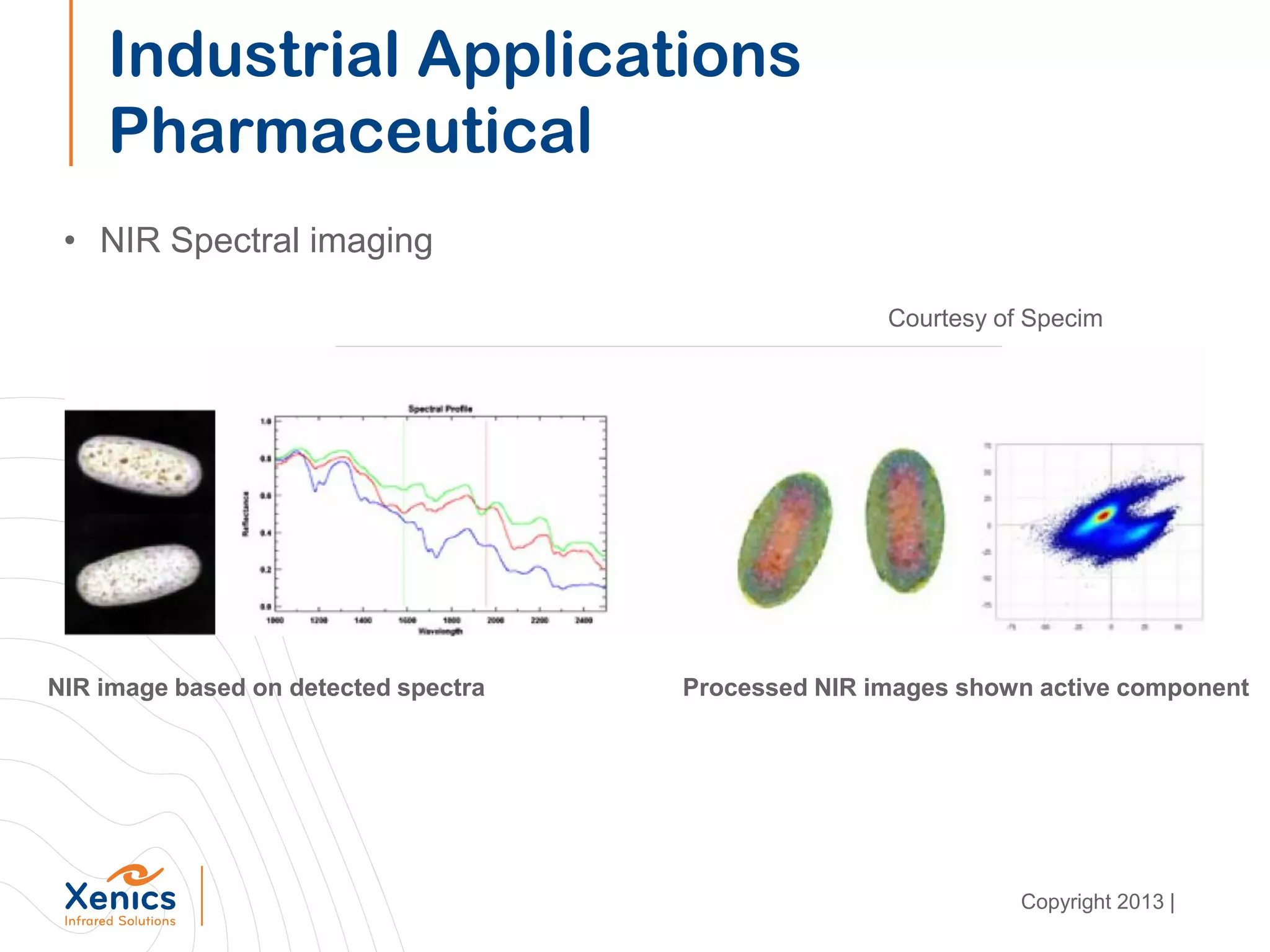

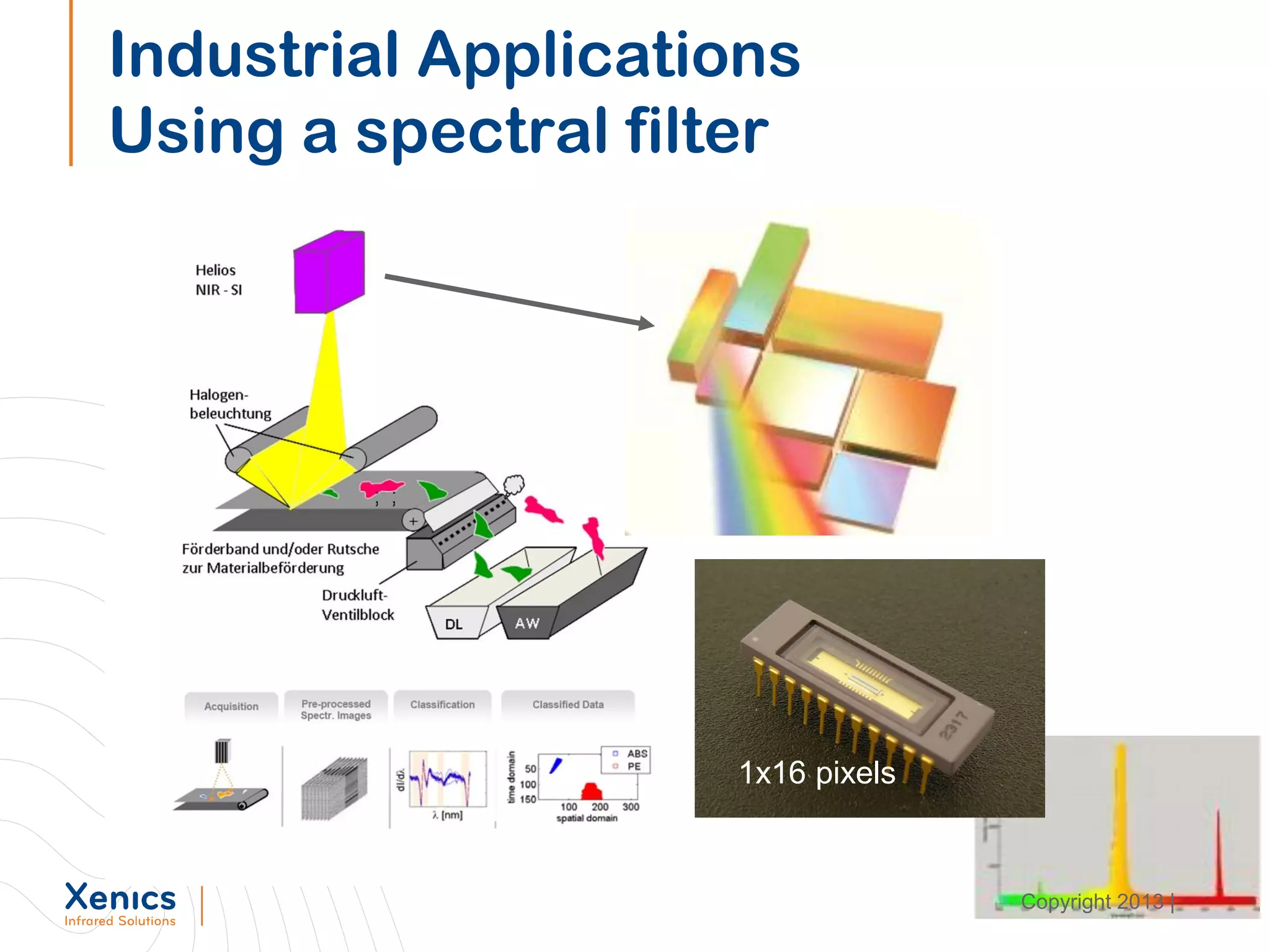

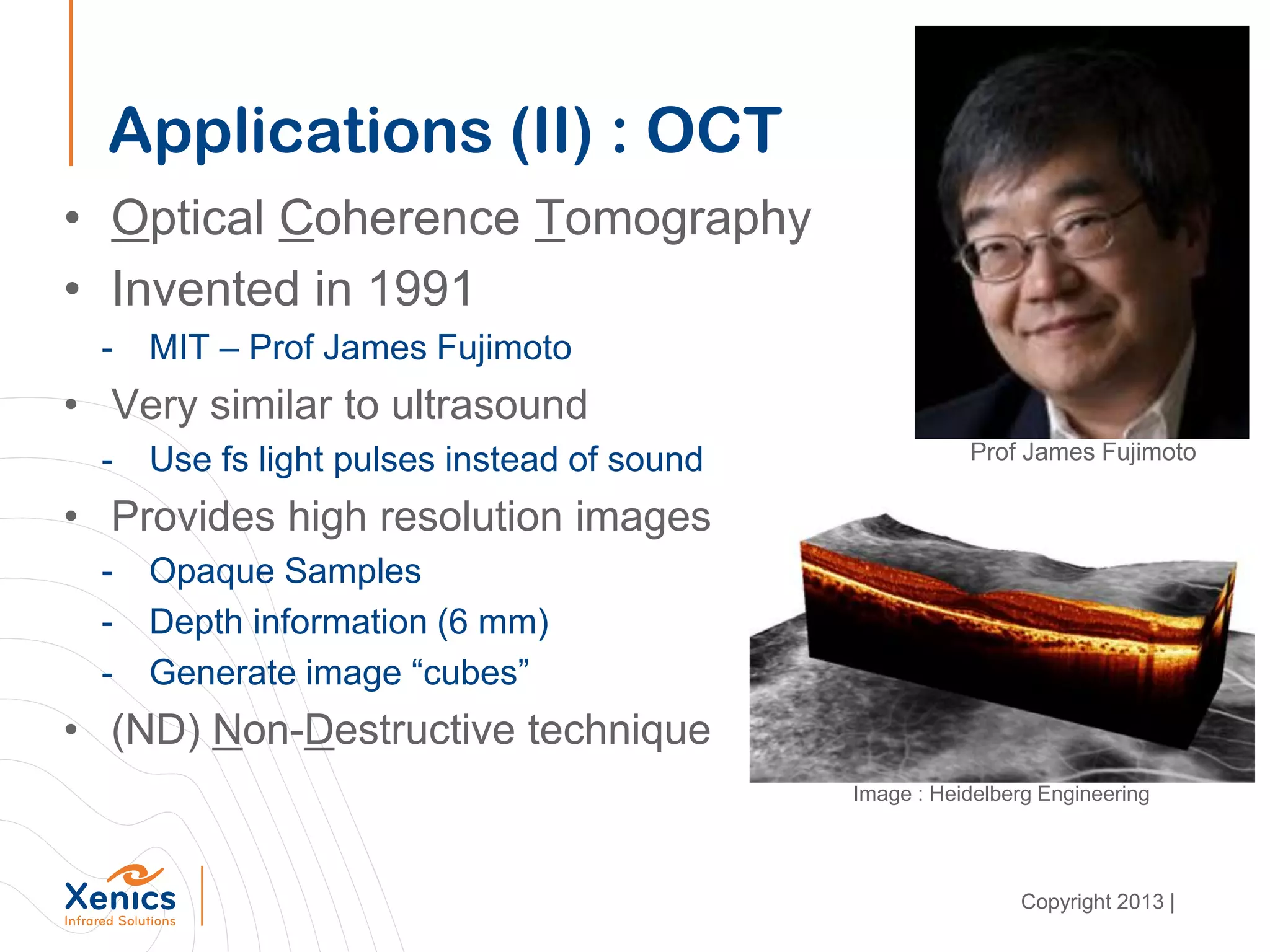

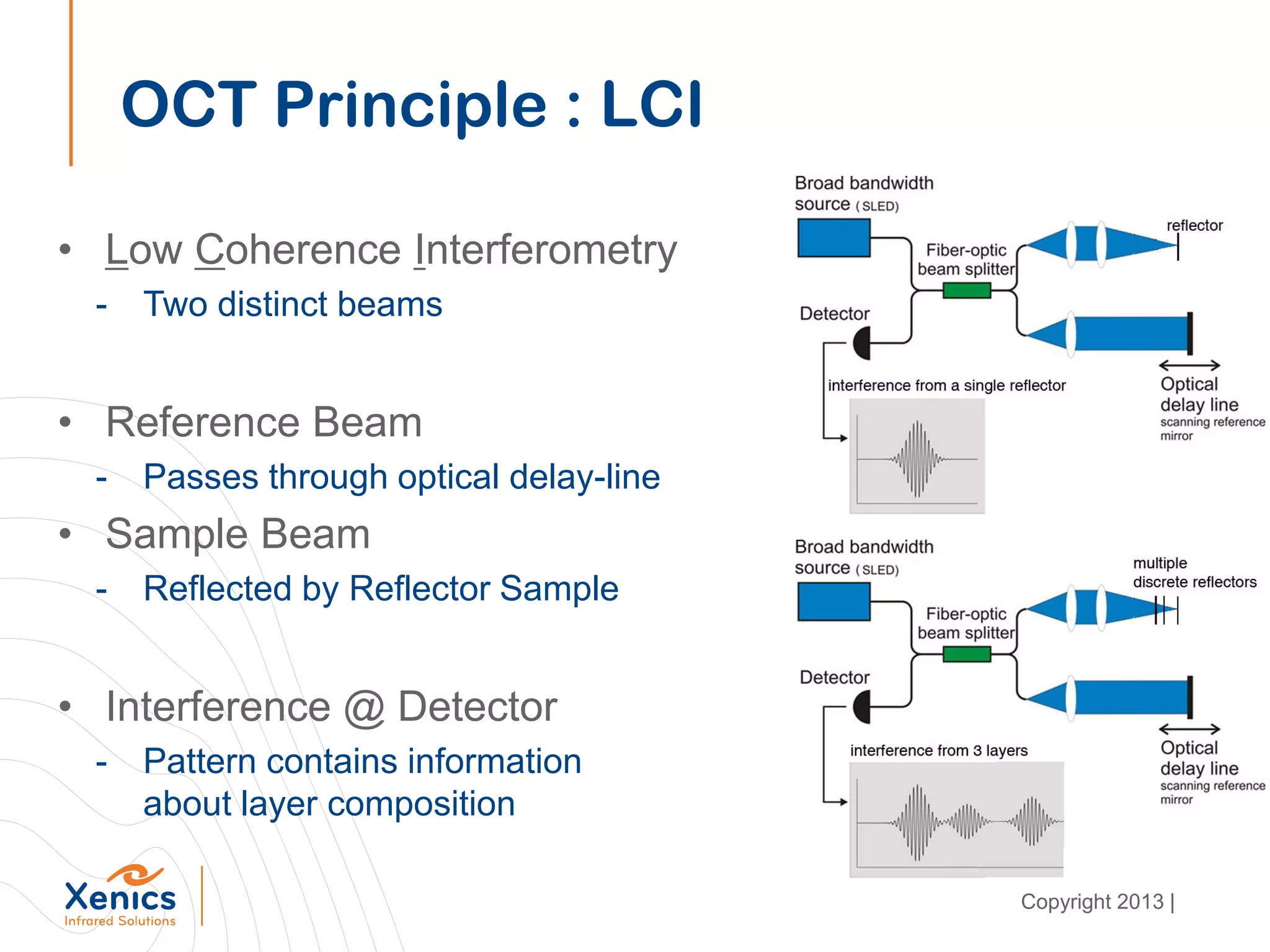

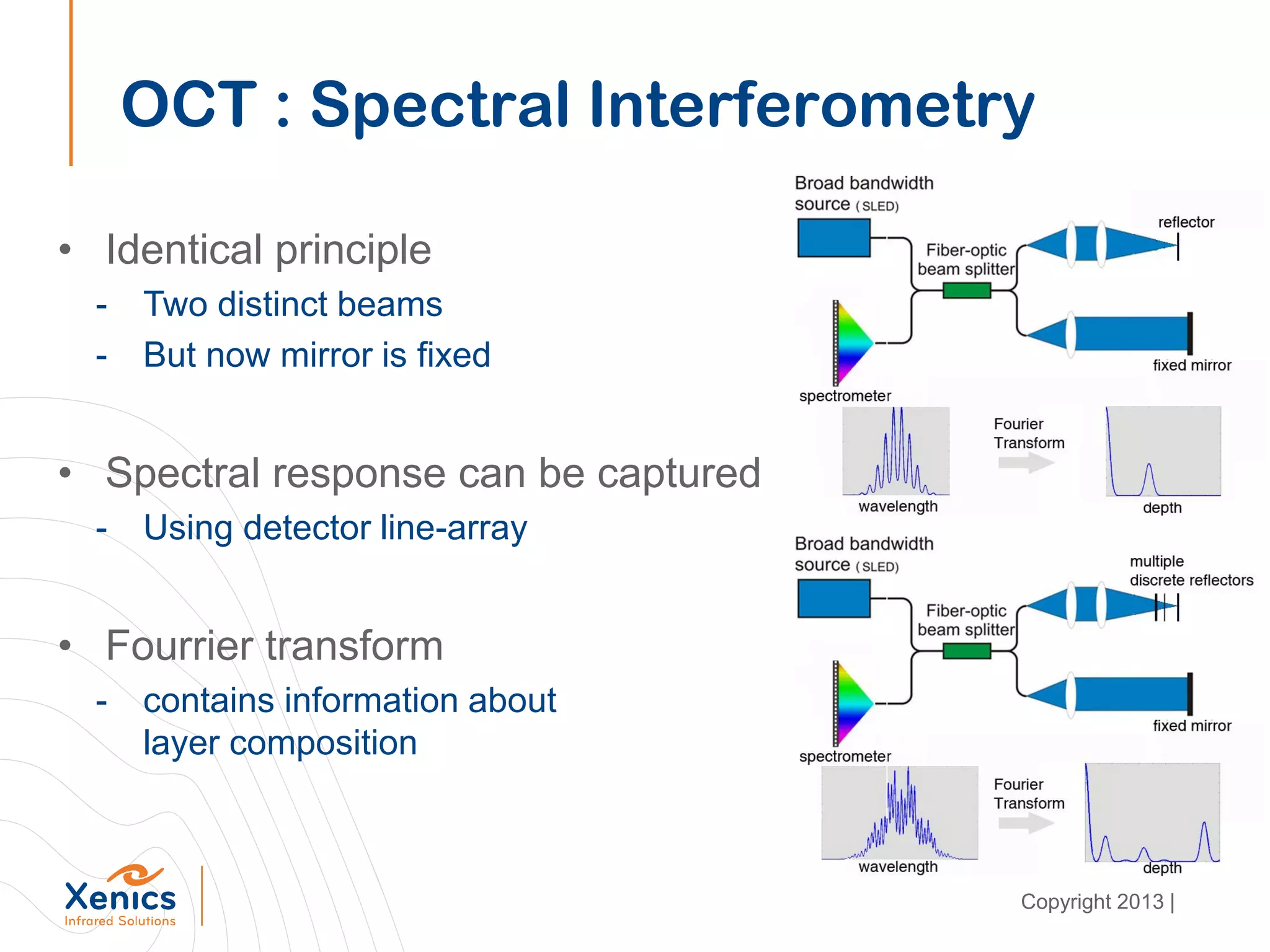

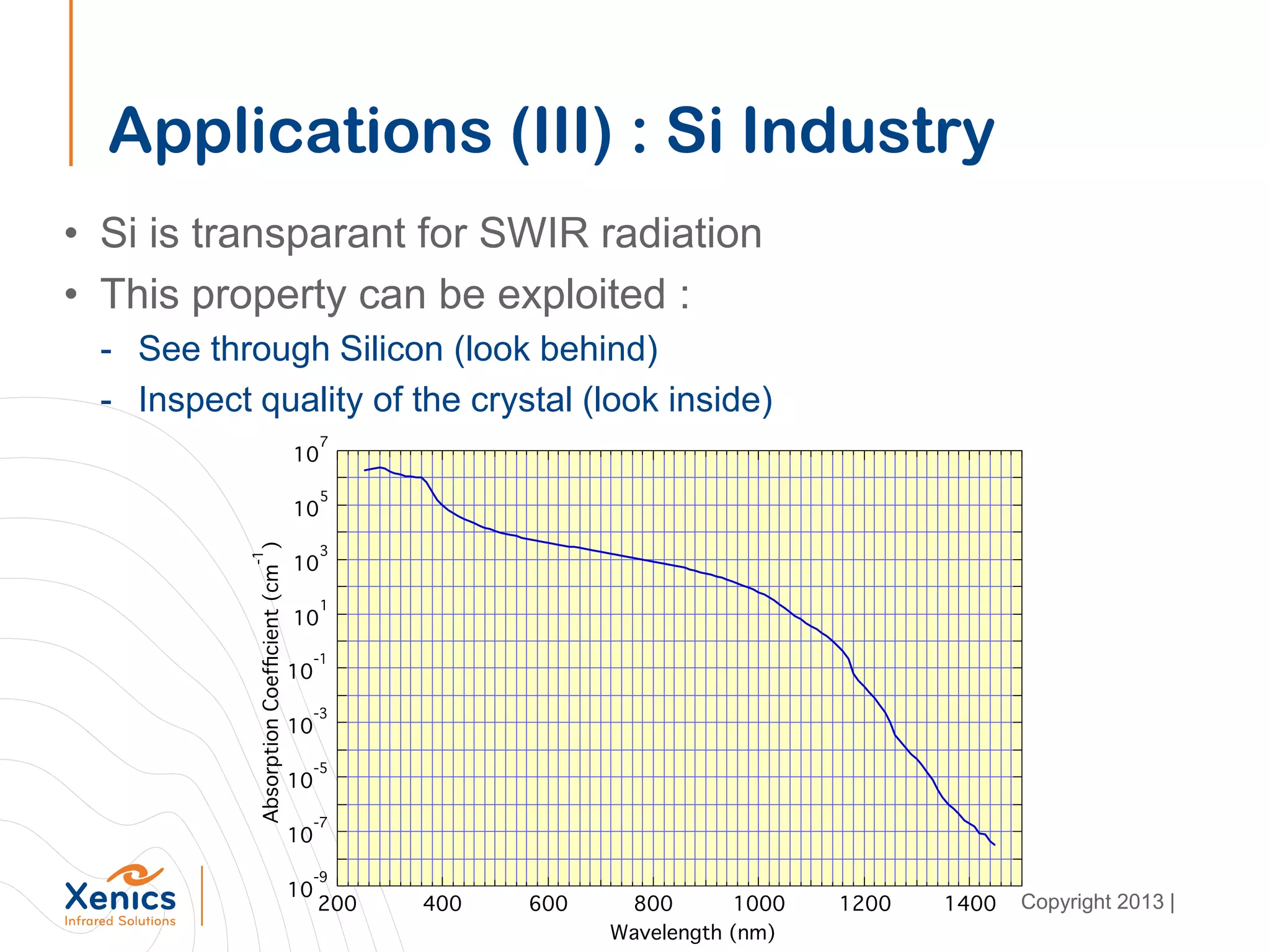

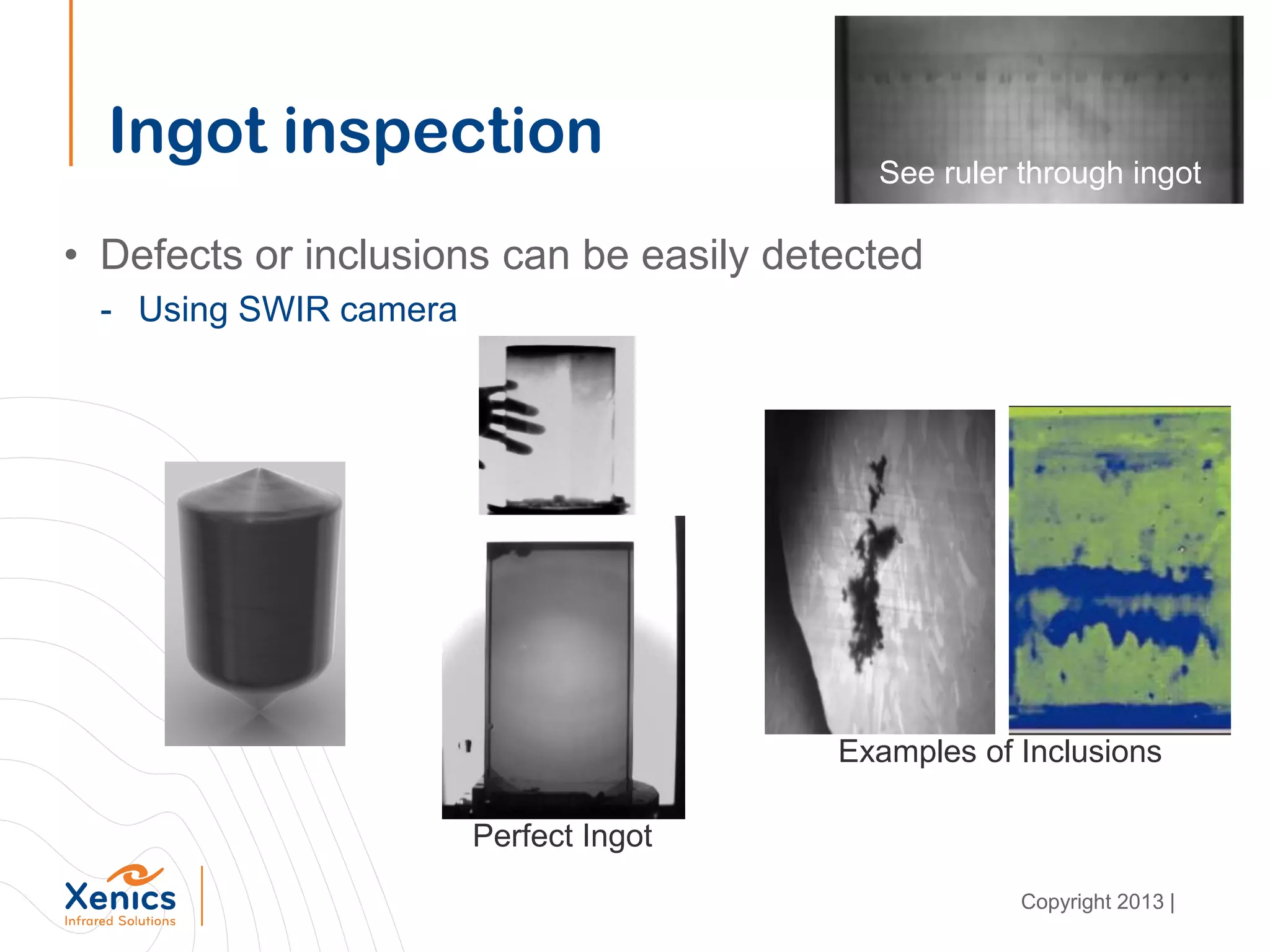

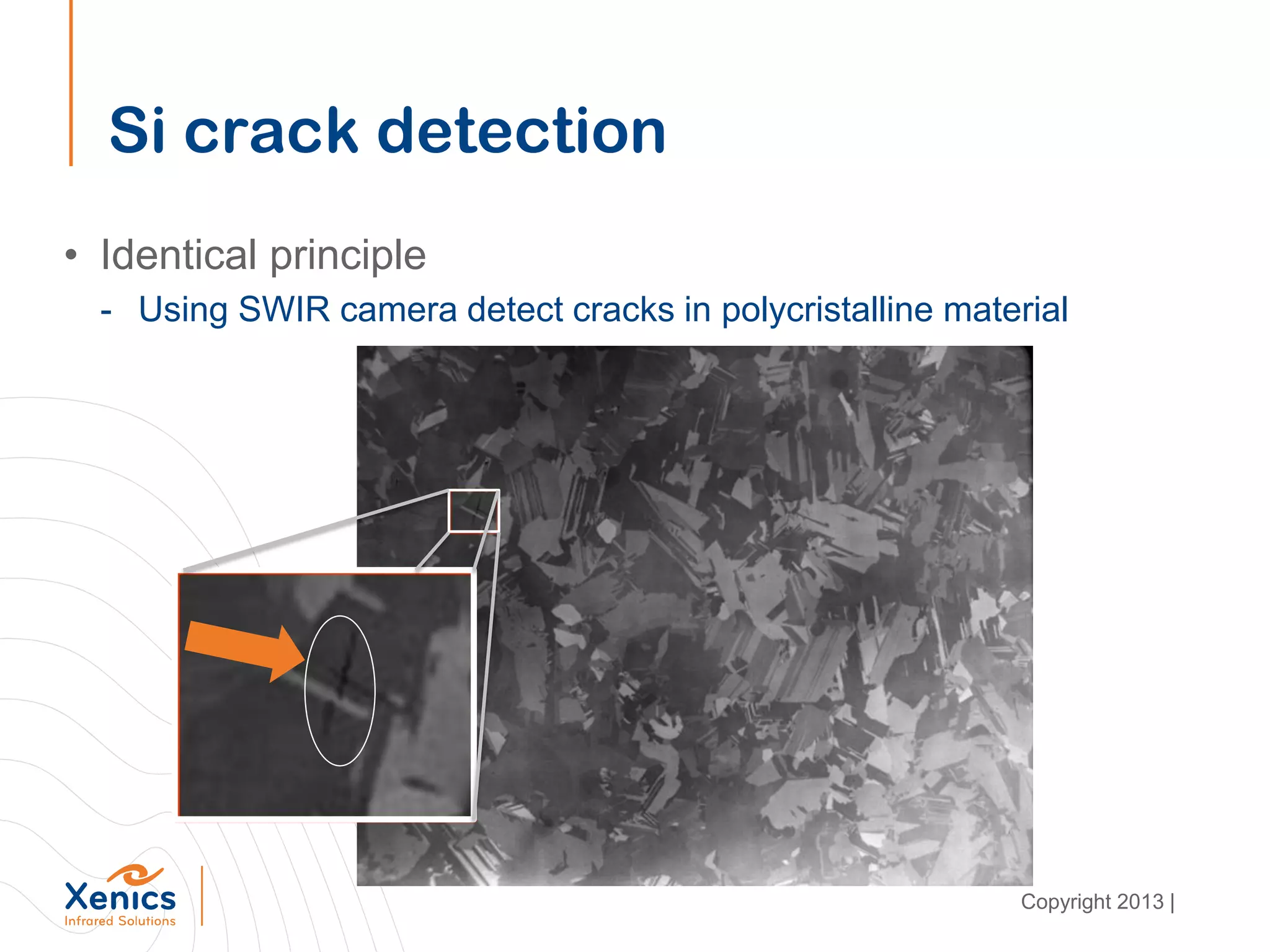

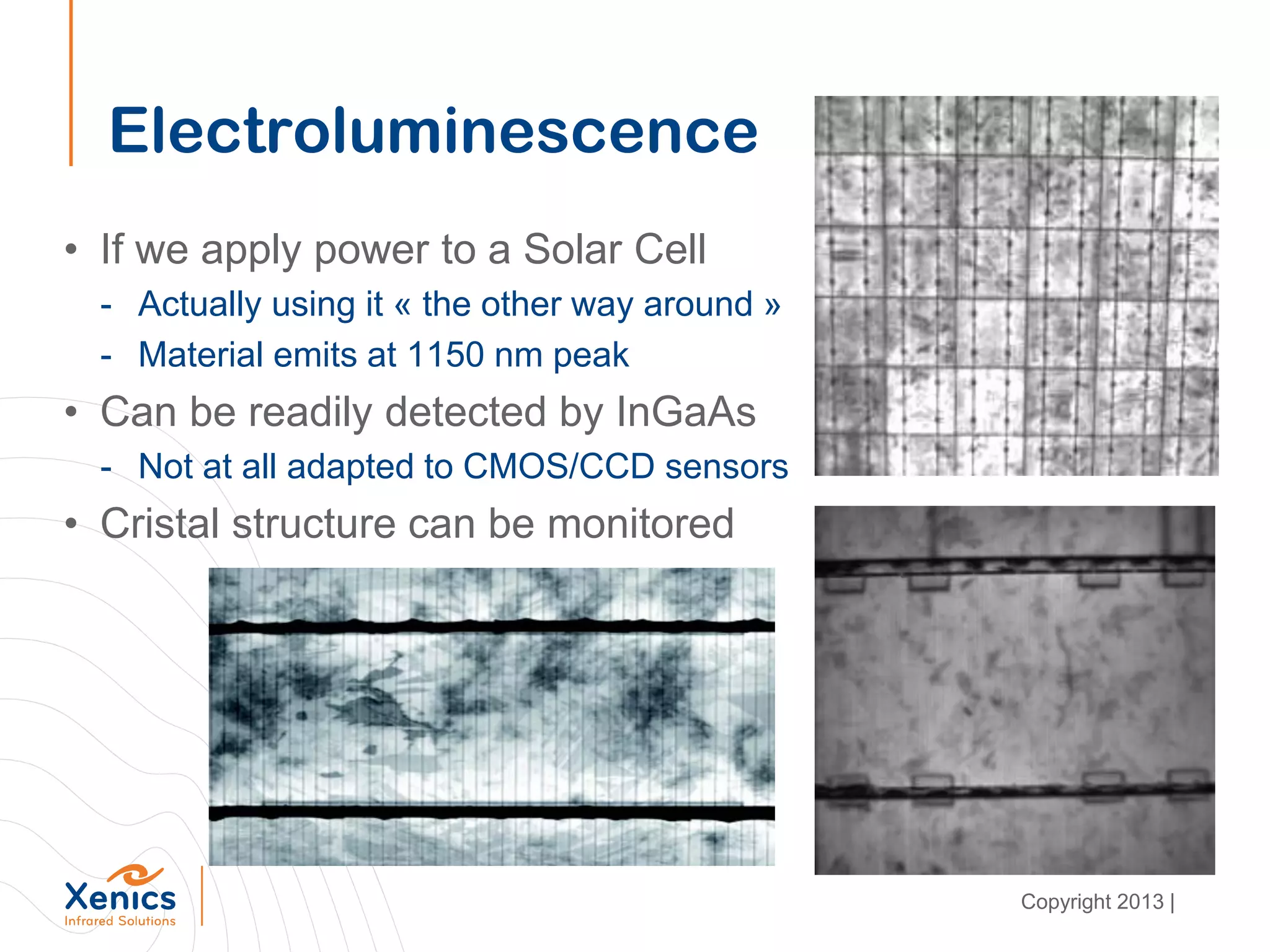

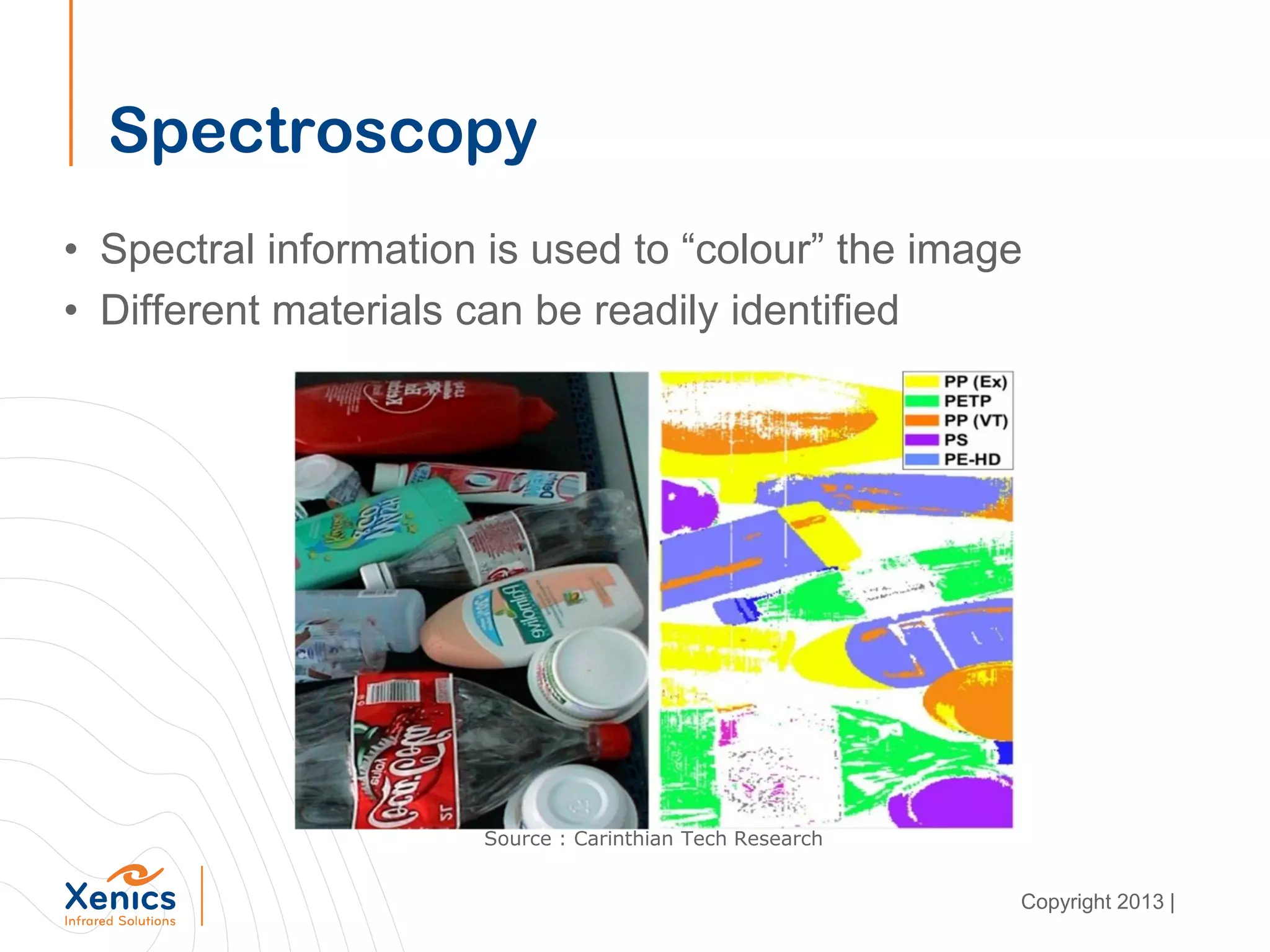

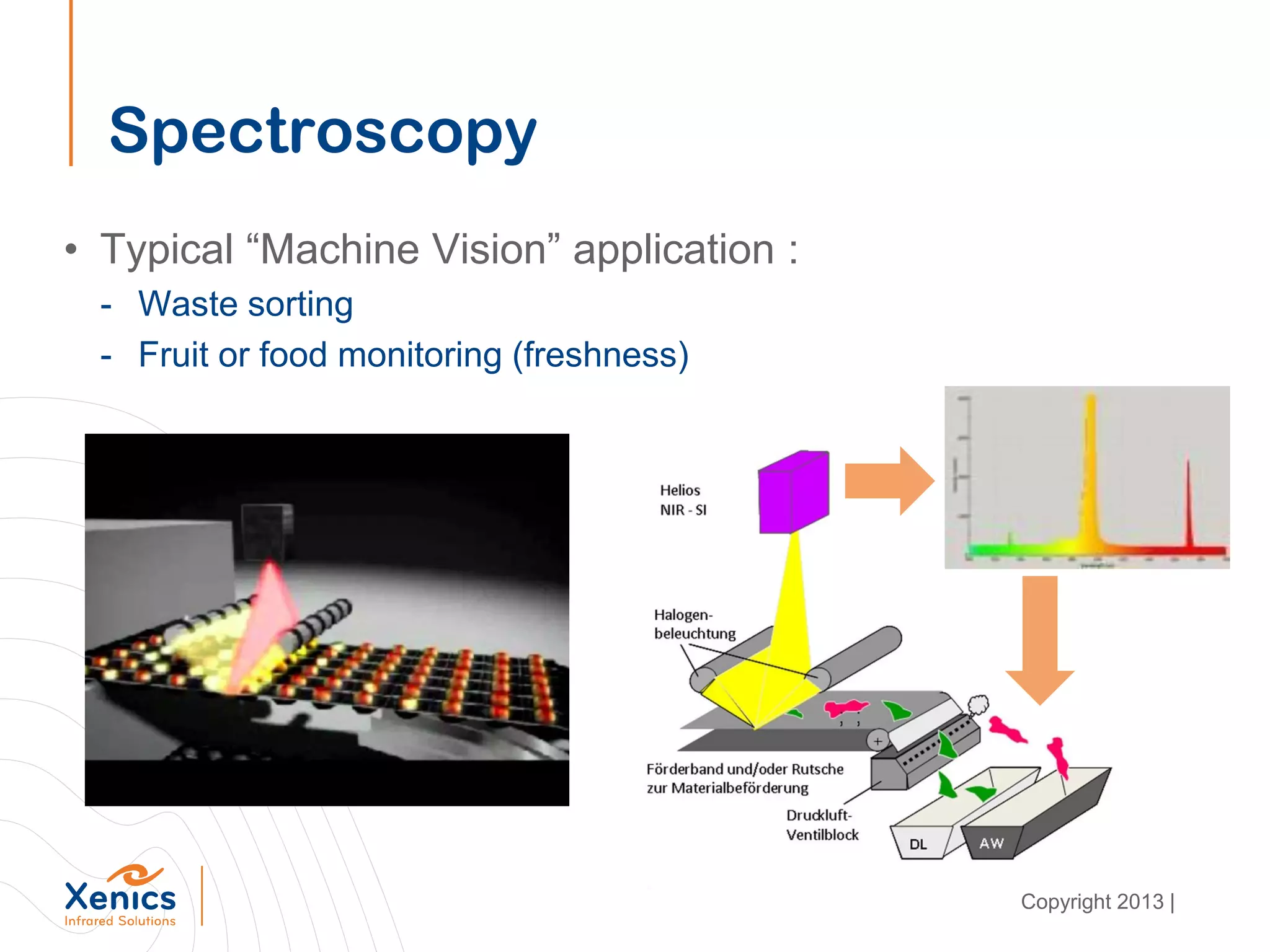

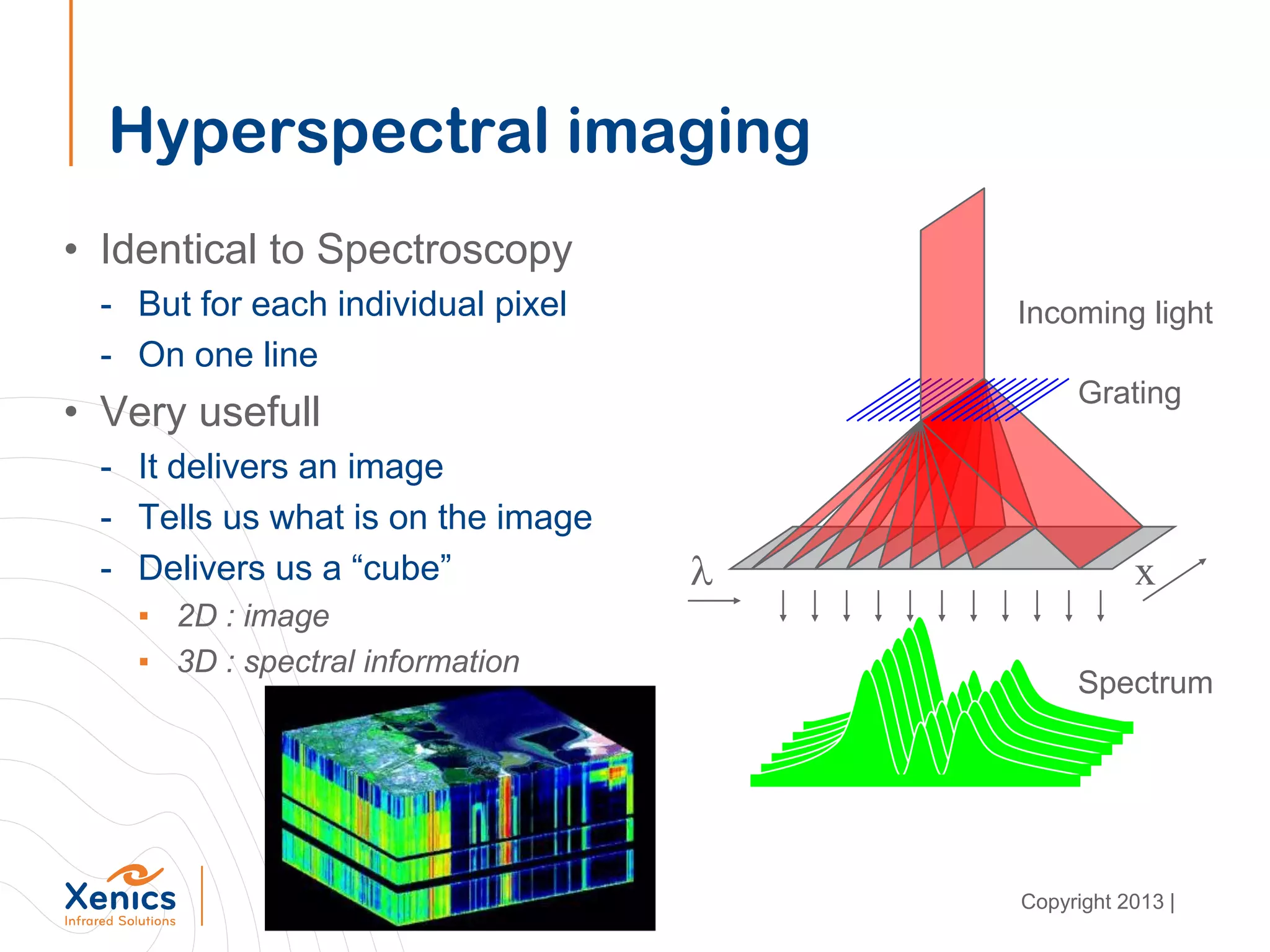

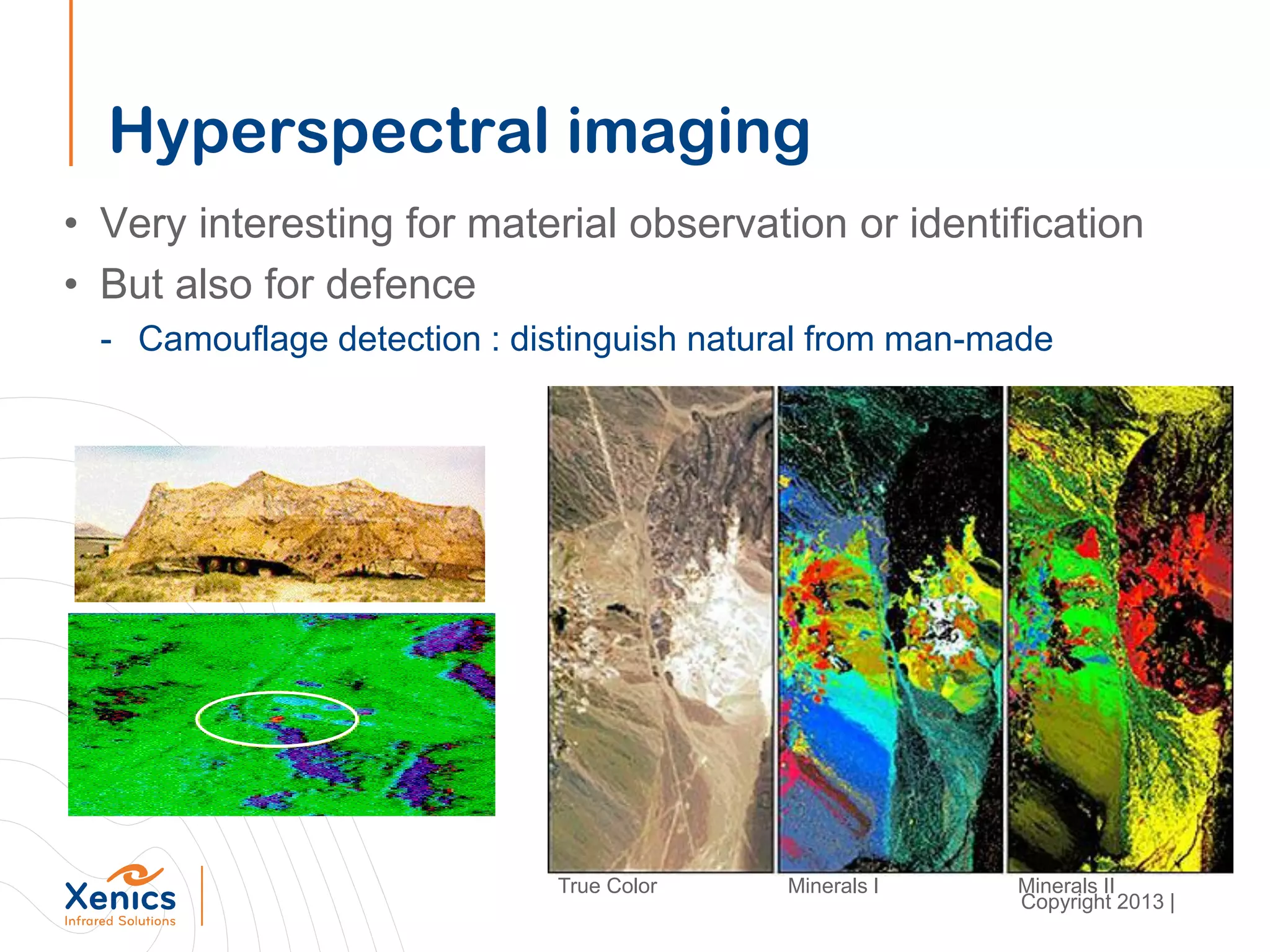

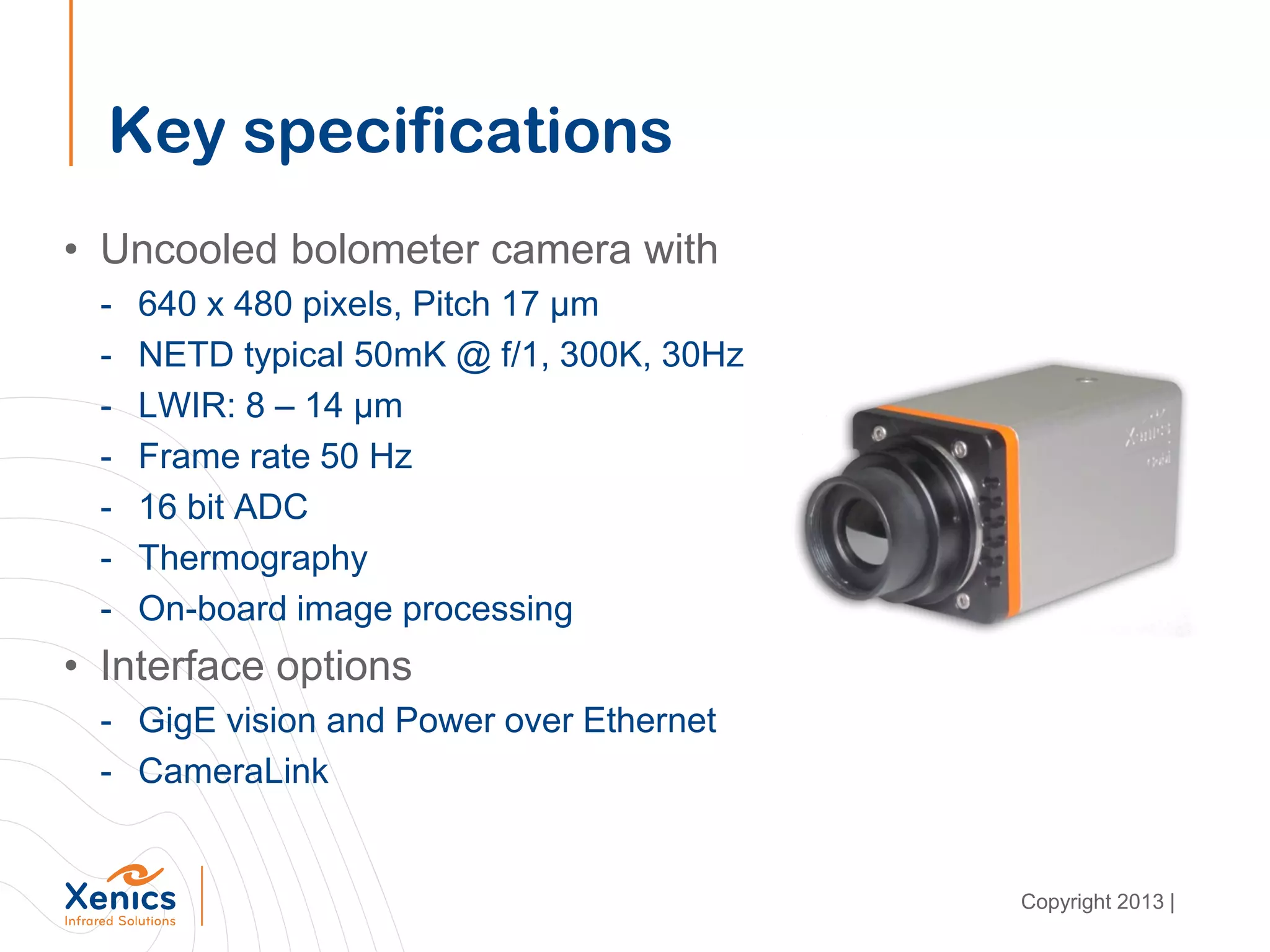

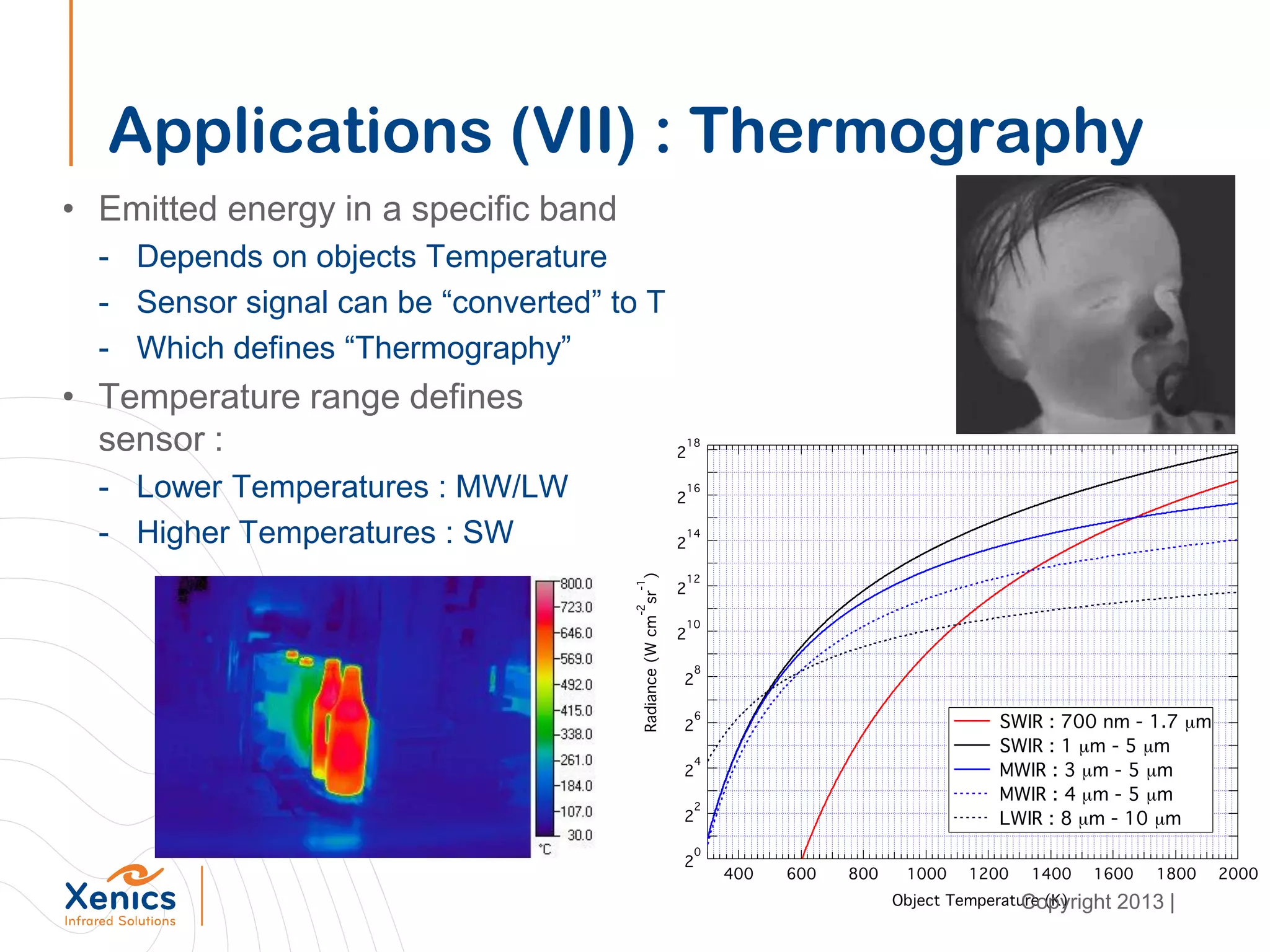

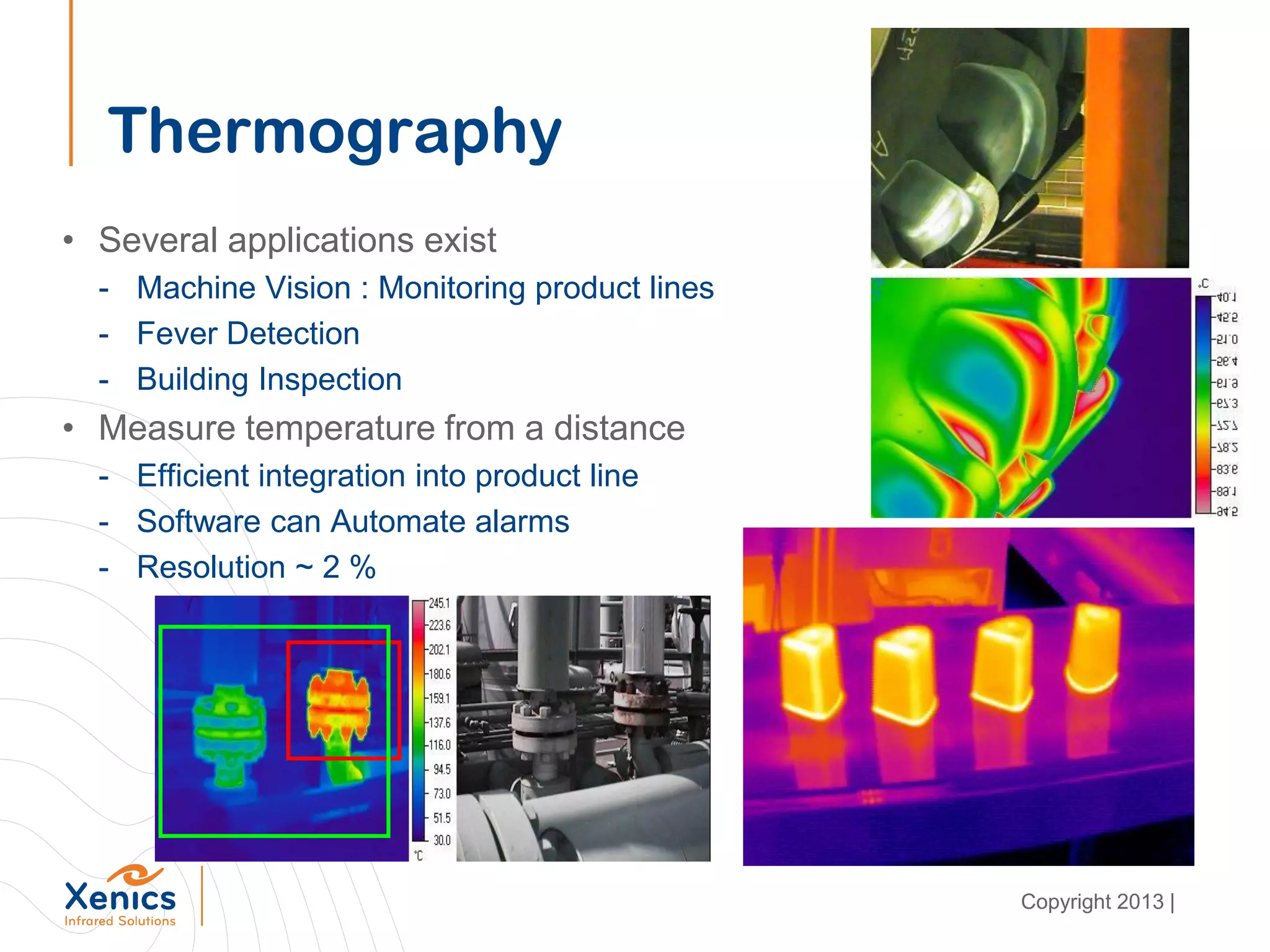

Xenics provides smart sensor systems based on modular designs for long wave and short wave infrared applications. Their product line includes SWIR cameras like the Bobcat 640 and Lynx series for applications such as art inspection, solar cell inspection, food sorting, and optical coherence tomography. They also offer LWIR cameras like the Gobi 640 for applications such as waste sorting. The cameras use hybrid integration of detectors and readout circuits and have interchangeable lenses and interfaces like GigE, CameraLink, and CoaXpress.