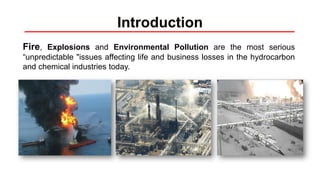

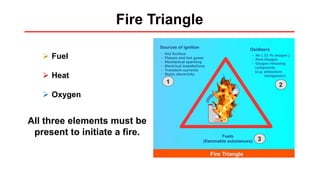

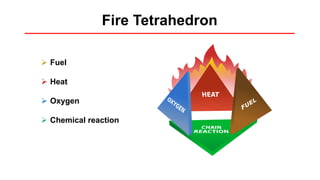

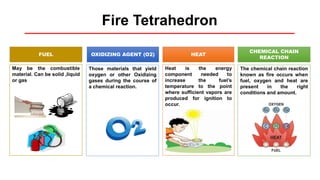

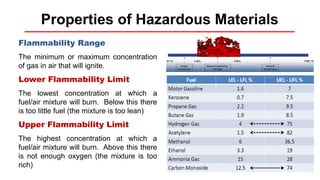

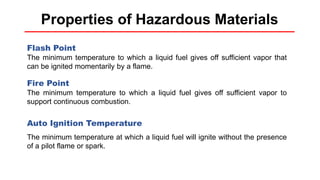

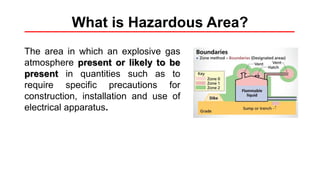

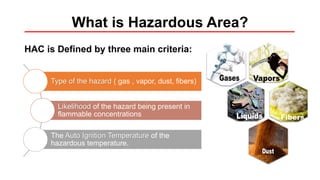

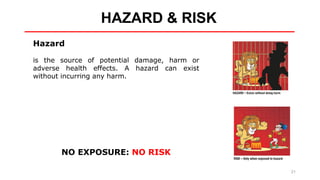

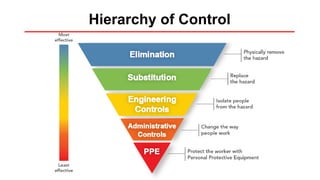

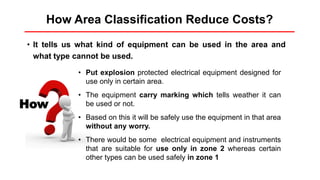

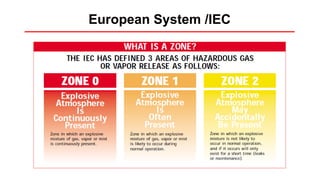

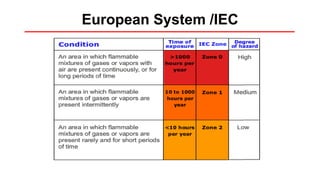

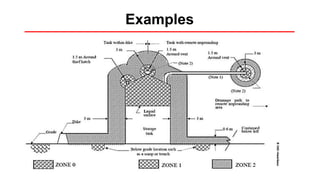

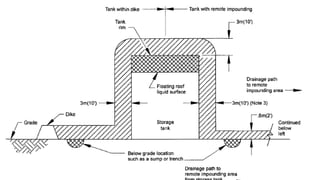

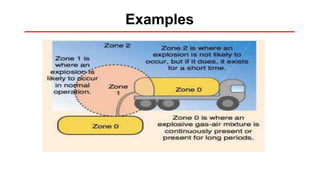

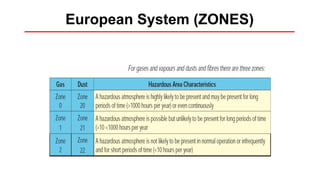

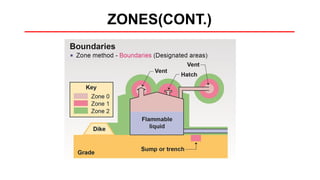

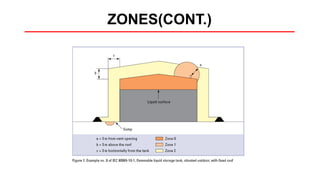

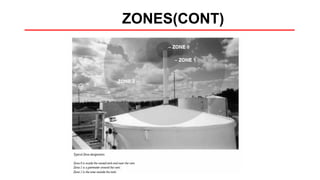

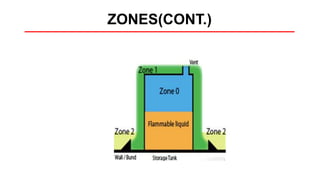

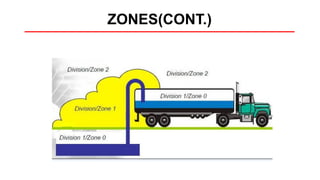

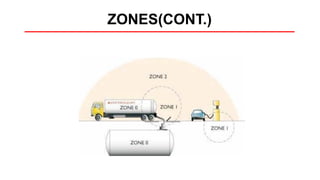

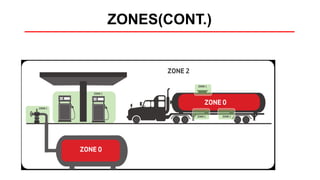

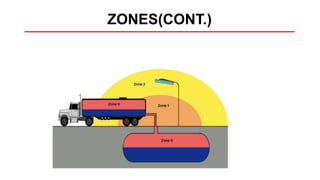

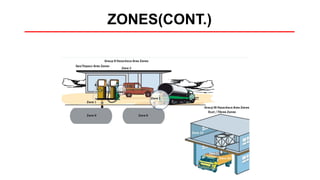

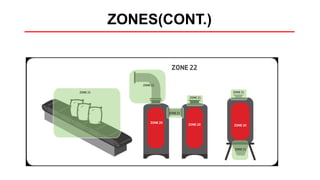

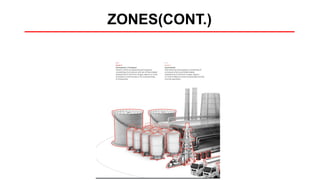

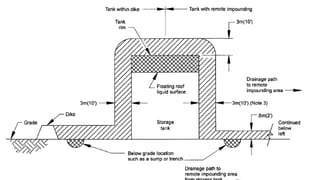

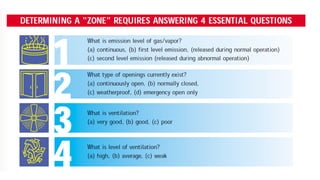

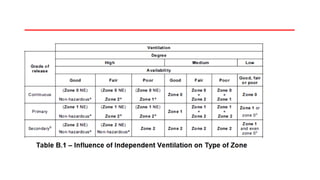

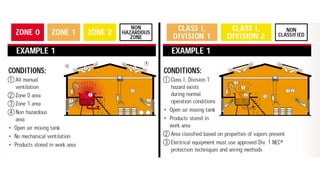

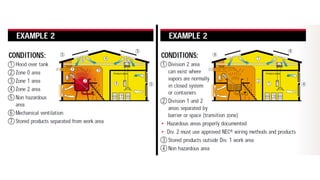

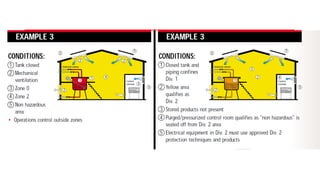

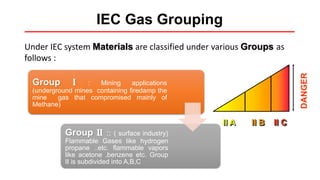

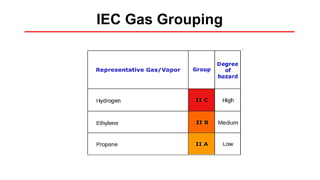

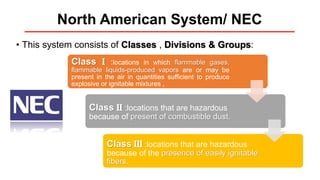

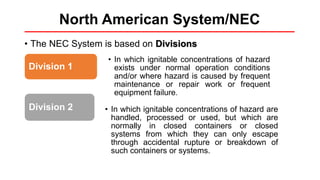

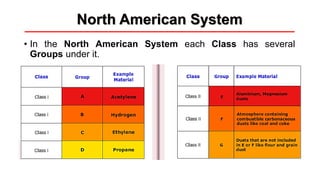

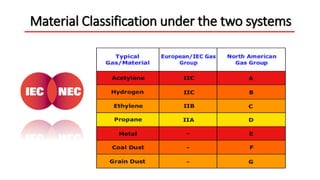

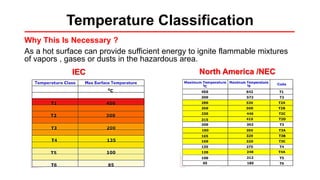

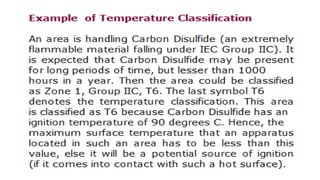

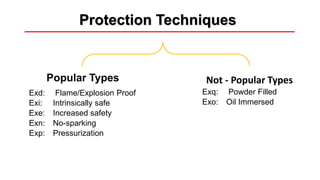

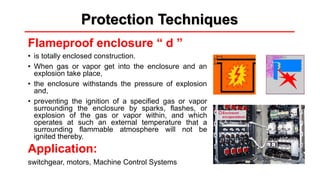

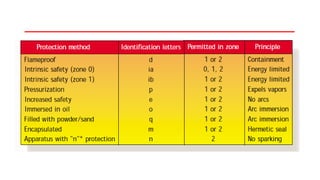

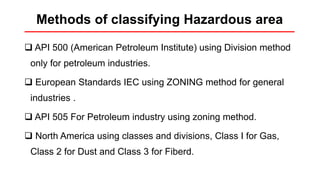

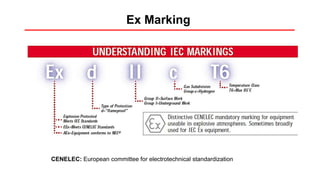

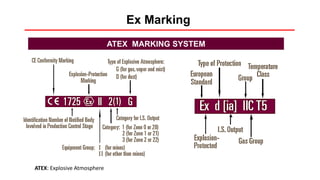

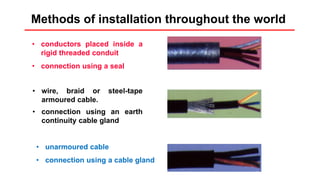

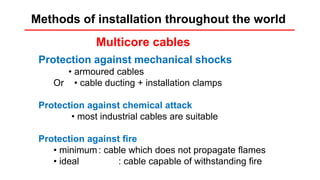

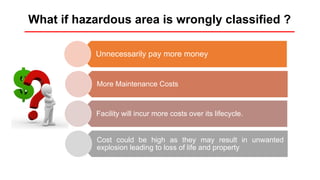

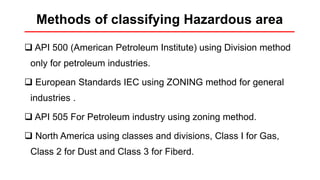

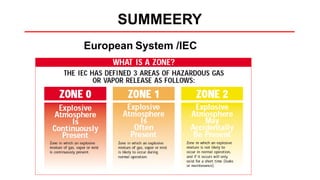

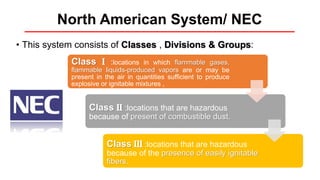

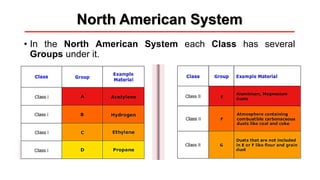

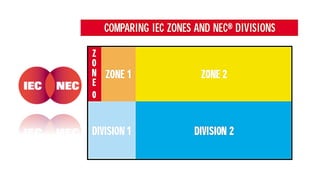

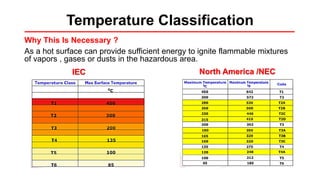

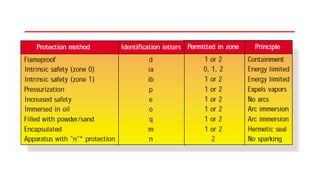

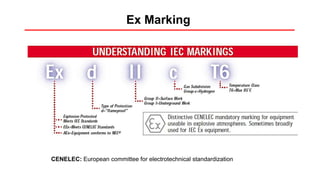

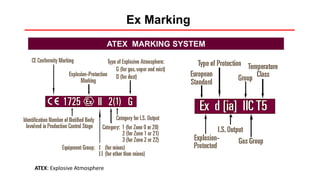

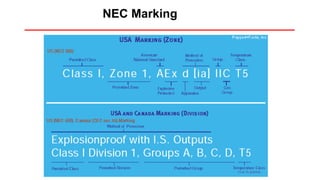

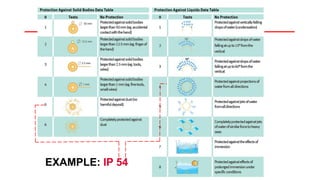

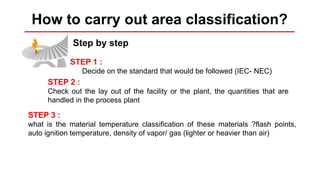

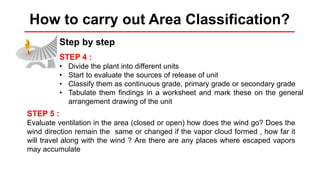

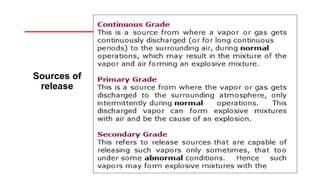

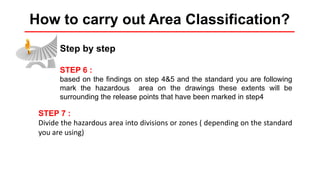

The document discusses hazardous area classification to mitigate risks of fire and explosions in the hydrocarbon and chemical industries. It explains key concepts such as the fire triangle, explosion properties, and methods for classifying hazardous areas using both European and North American standards. Effective area classification is essential for safe operation and compliance, guiding the appropriate use of electrical equipment in potentially explosive environments.