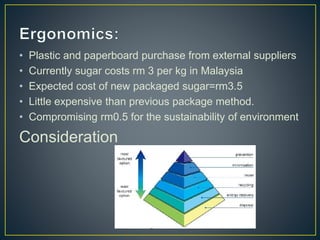

The document discusses weaknesses in current sugar packaging and proposes a new packaging solution. The current plastic packaging often tears, allowing sugar to spill out. It also cannot be resealed once opened. The document proposes a new packaging made of paperboard lined with polypropylene plastic. This new packaging would be more durable, allow viewing of sugar levels, enable controlled pouring, and be more environmentally friendly than current plastic packaging. It describes the proposed materials and manufacturing process in detail.