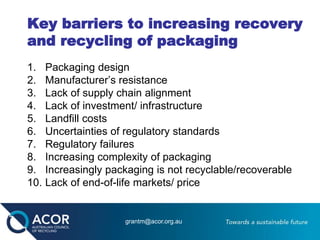

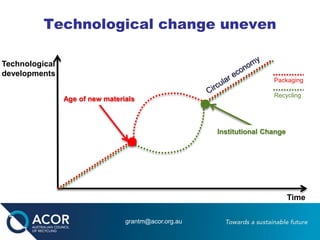

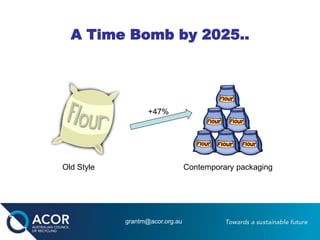

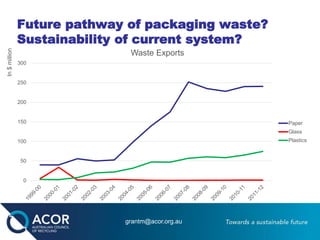

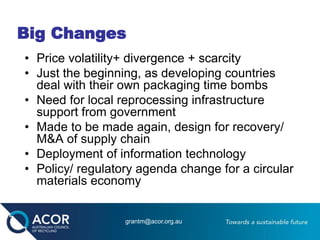

ACOR is a national peak representative body for the recycling and resource recovery industry in Australia. It lobbies governments for policies that support recycling organizations and advises its members. Key barriers to increasing packaging recycling include packaging design, lack of investment in infrastructure, and the fact that some packaging is not recyclable. Current trends in packaging design focus on life cycle assessments, while recycling trends involve new technologies. Regulatory trends are moving towards internalizing externalities and requiring design for recovery of packaging materials. International trends show other countries increasingly restricting non-recyclable packaging and imports of contaminated plastics in an effort to transition to a circular economy model.