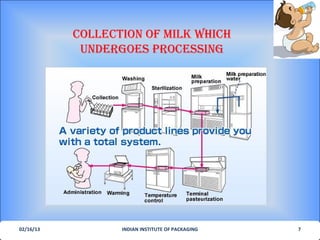

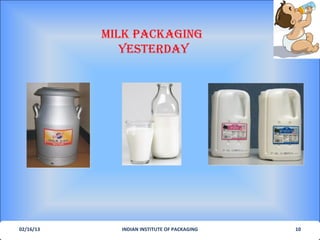

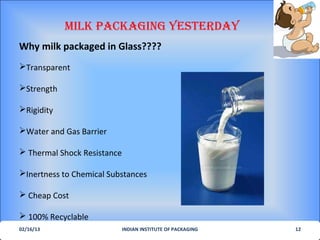

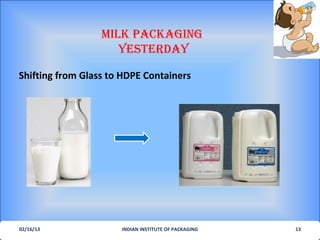

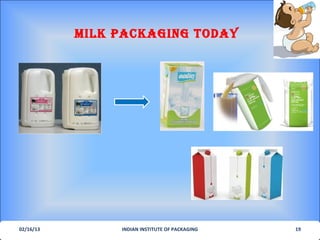

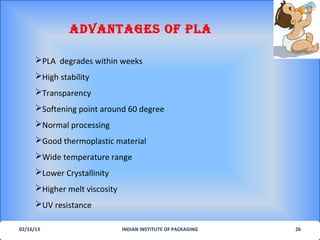

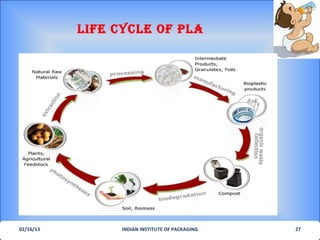

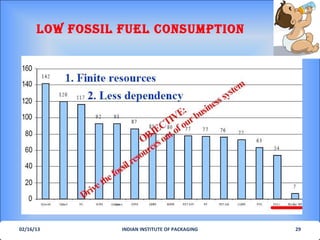

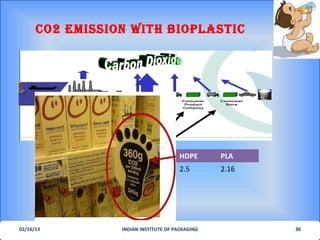

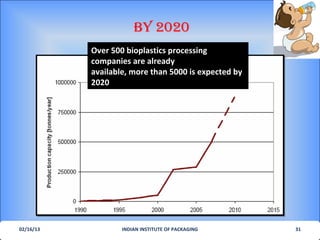

This presentation discusses the history and future of milk packaging. It begins by describing how milk was traditionally collected and packaged in glass bottles for delivery. It then explains why packaging shifted to use HDPE bottles and cartons, which are lighter weight and address issues with glass. The presentation concludes by proposing that the future of milk packaging lies in using biodegradable thermoformed bottles made from PLA, which is derived from corn starch. PLA packaging would have environmental benefits like lower carbon emissions compared to traditional plastics.