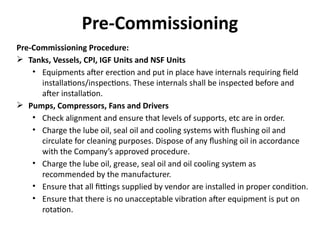

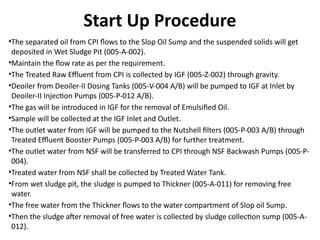

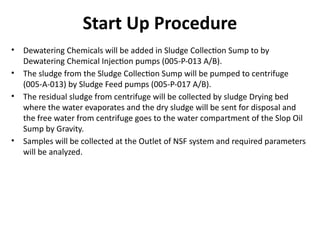

The document outlines the procedure for pre-commissioning and commissioning of an effluent treatment plant (ETP) project, detailing the systems and equipment involved, as well as checklists and procedures for each stage. It describes the steps for pre-commissioning, start-up, shut-down, and commissioning, ensuring all installations are complete and operationally safe for treating produced water. The performance guarantee test run will follow a successful 72-hour operation, confirming compliance with specified parameters for disposal.