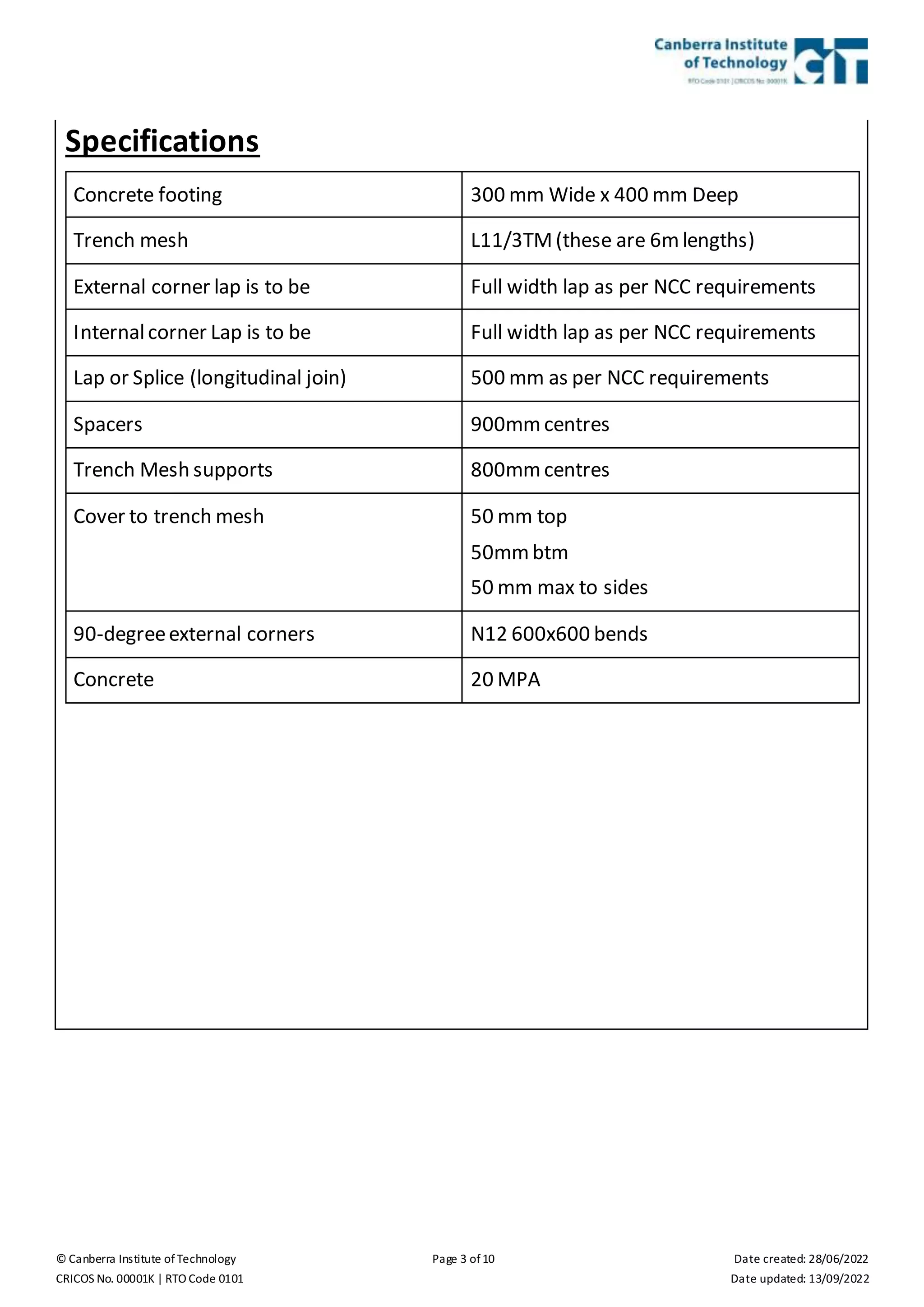

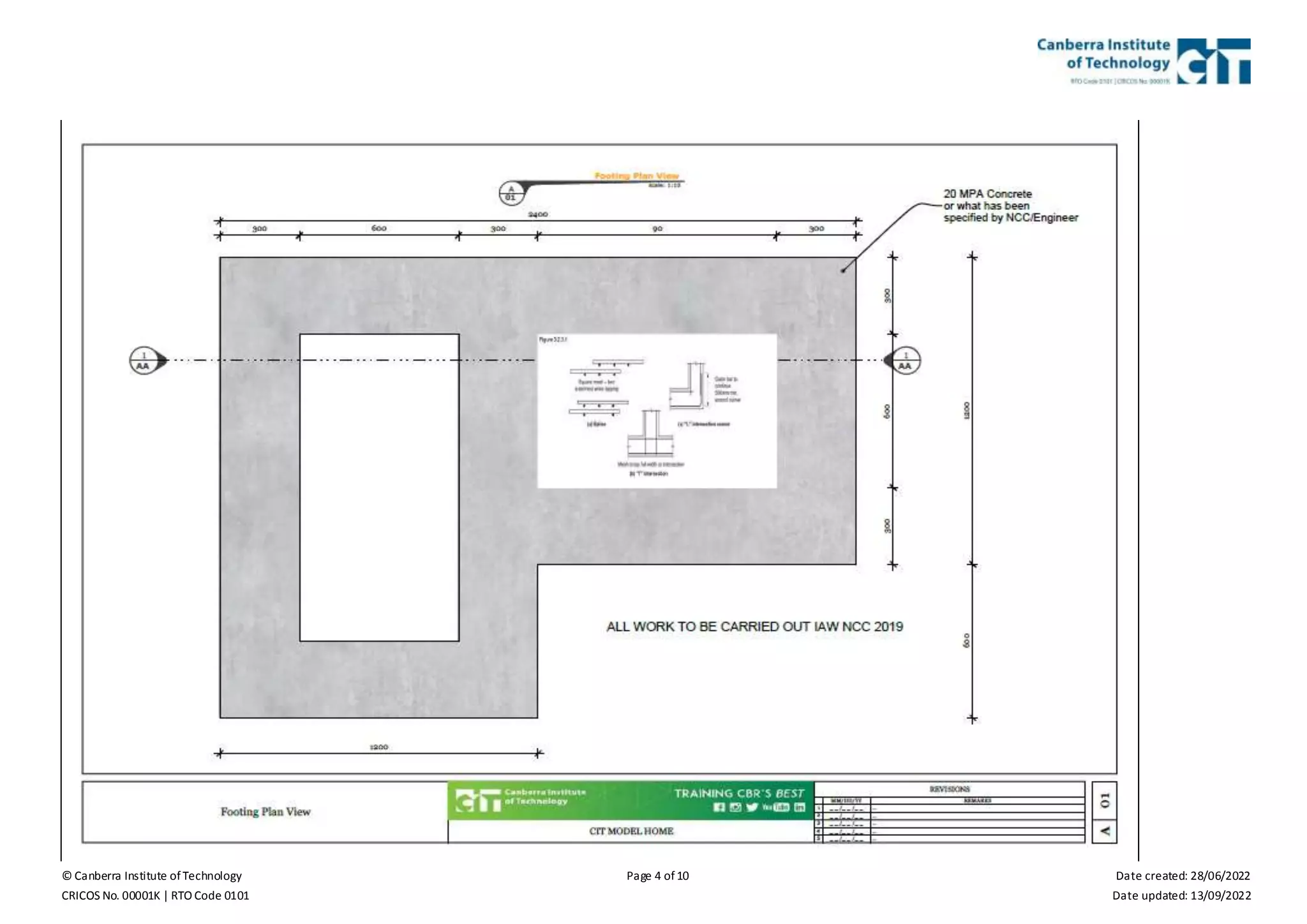

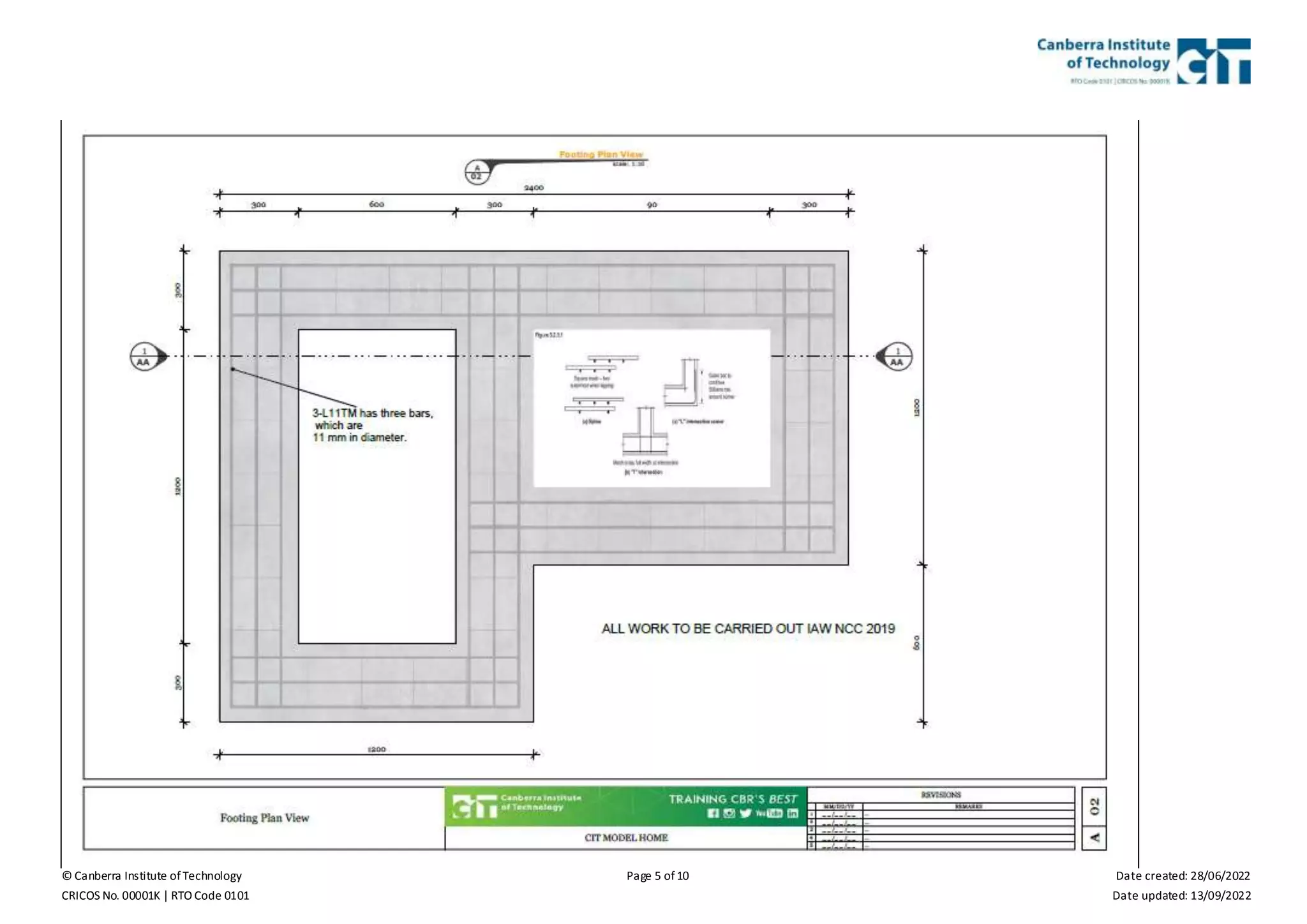

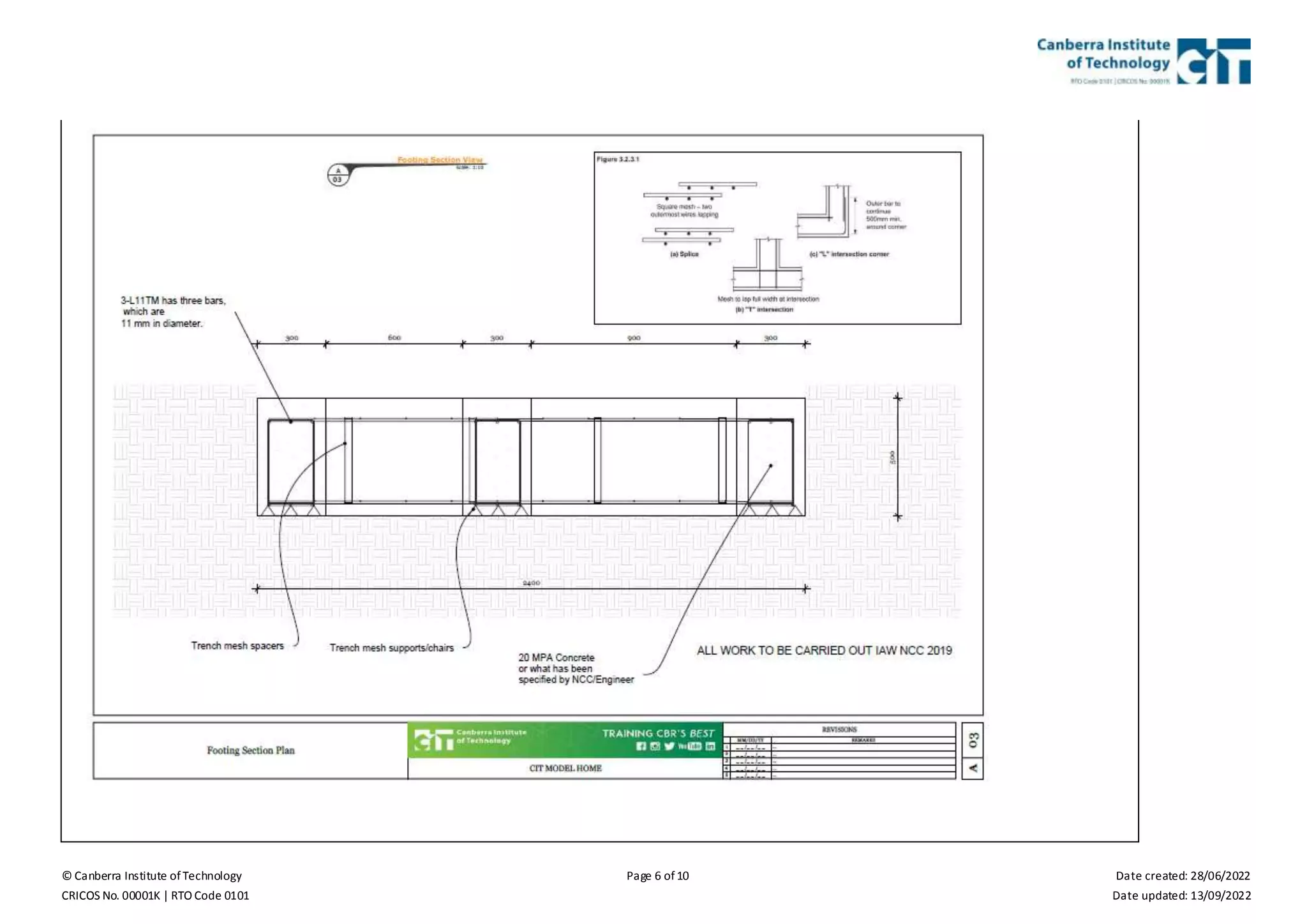

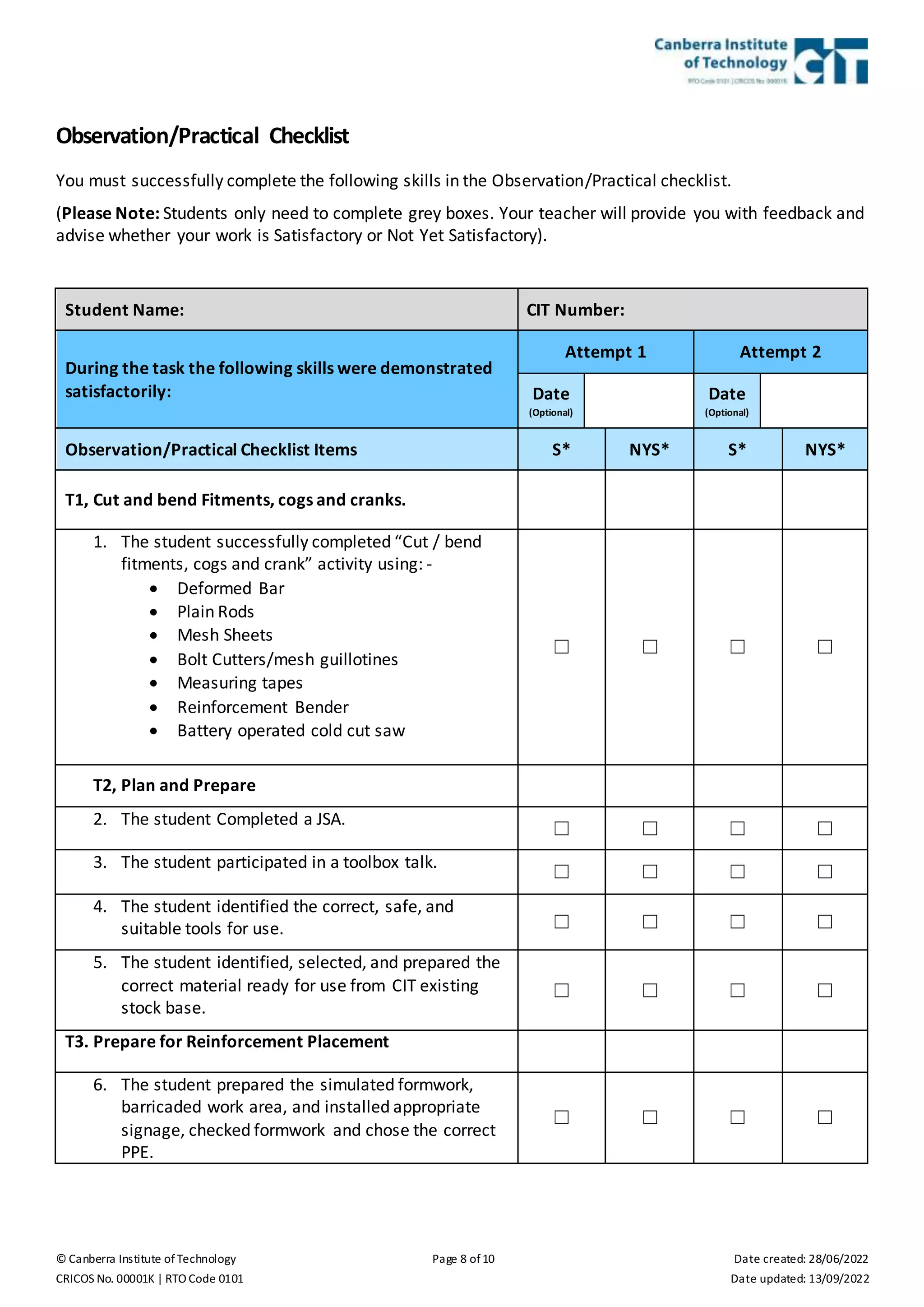

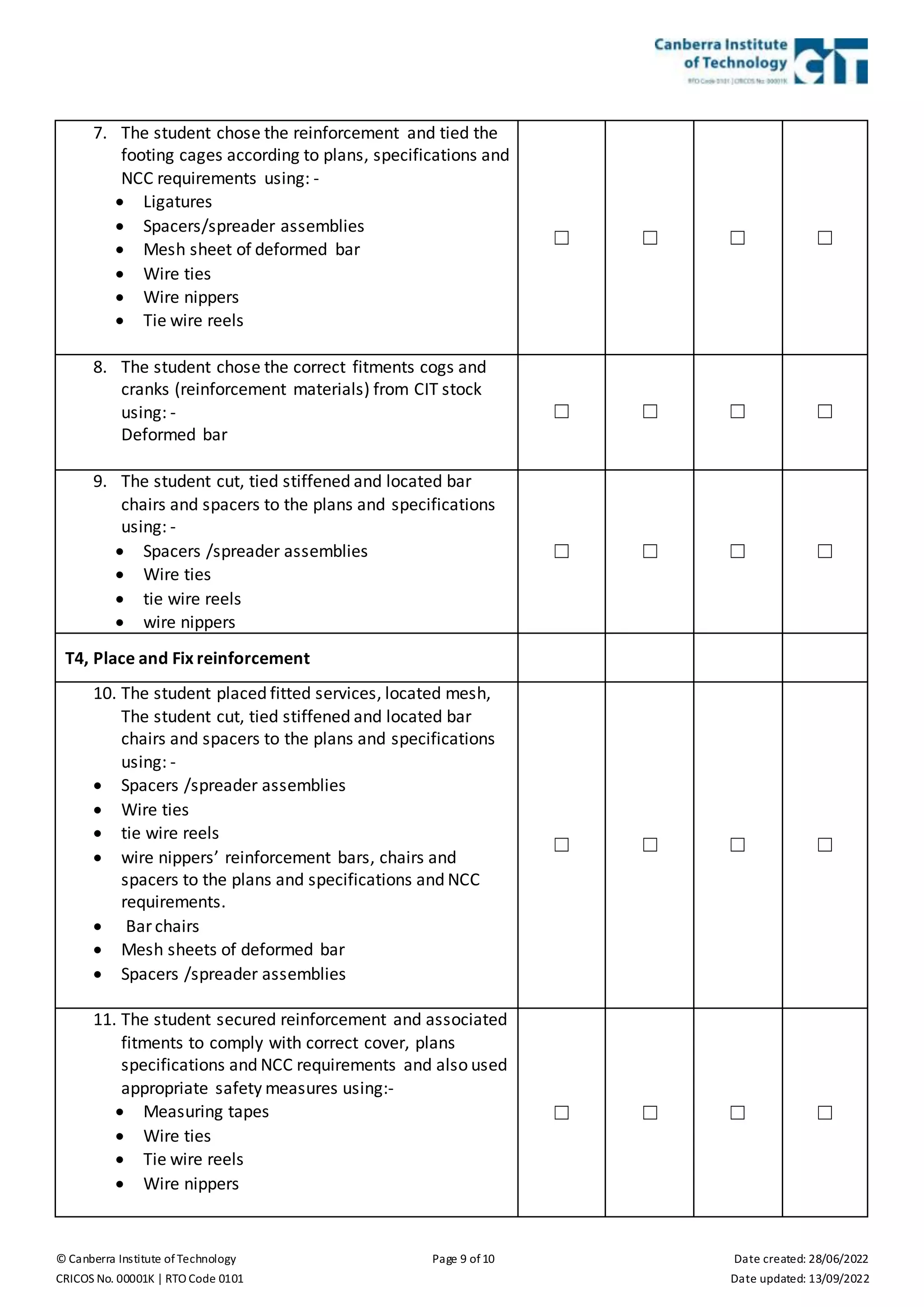

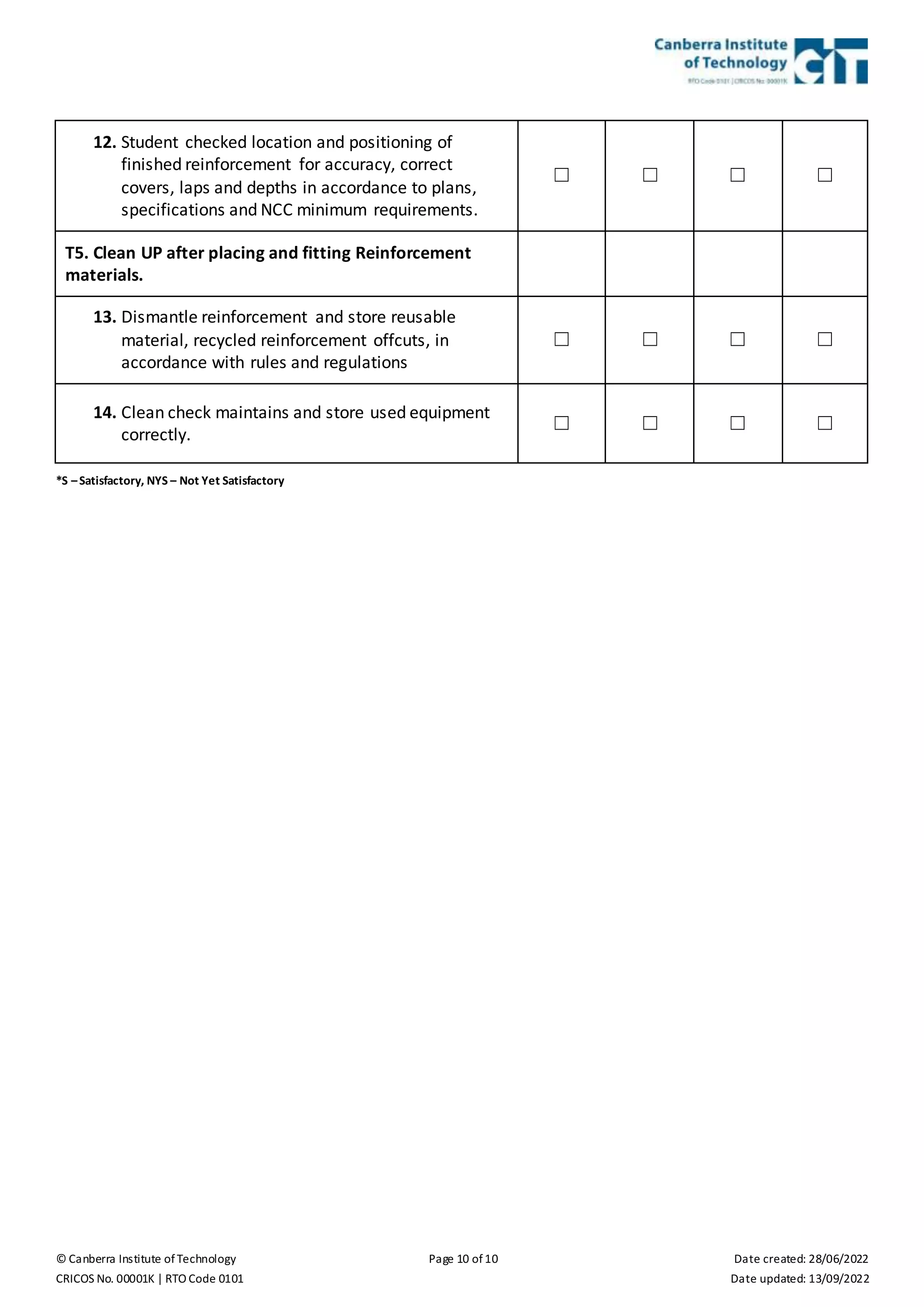

The document provides instructions and specifications for a practical assessment requiring a student to correctly place and fix reinforcement material into simulated formwork. The student must read plans, measure, cut, and bend reinforcement materials to construct footing cages. They must then install the cages in the formwork with proper laps, splices, and cover according to specifications and code requirements. Finally, the student must clean up their work area and store equipment properly. The assessor will observe and provide feedback on the student's work.