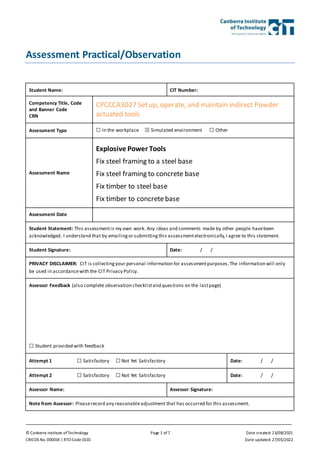

The document provides instructions for a practical assessment involving the setup and use of indirect powder actuated tools to fix steel and timber framing to concrete and steel bases across 4 stations. Students are required to correctly calculate fixing lengths, safely operate the tools, and maintain the tools and work area. The assessment will evaluate students' ability to plan, prepare, operate and maintain powder actuated tools according to competency standards.