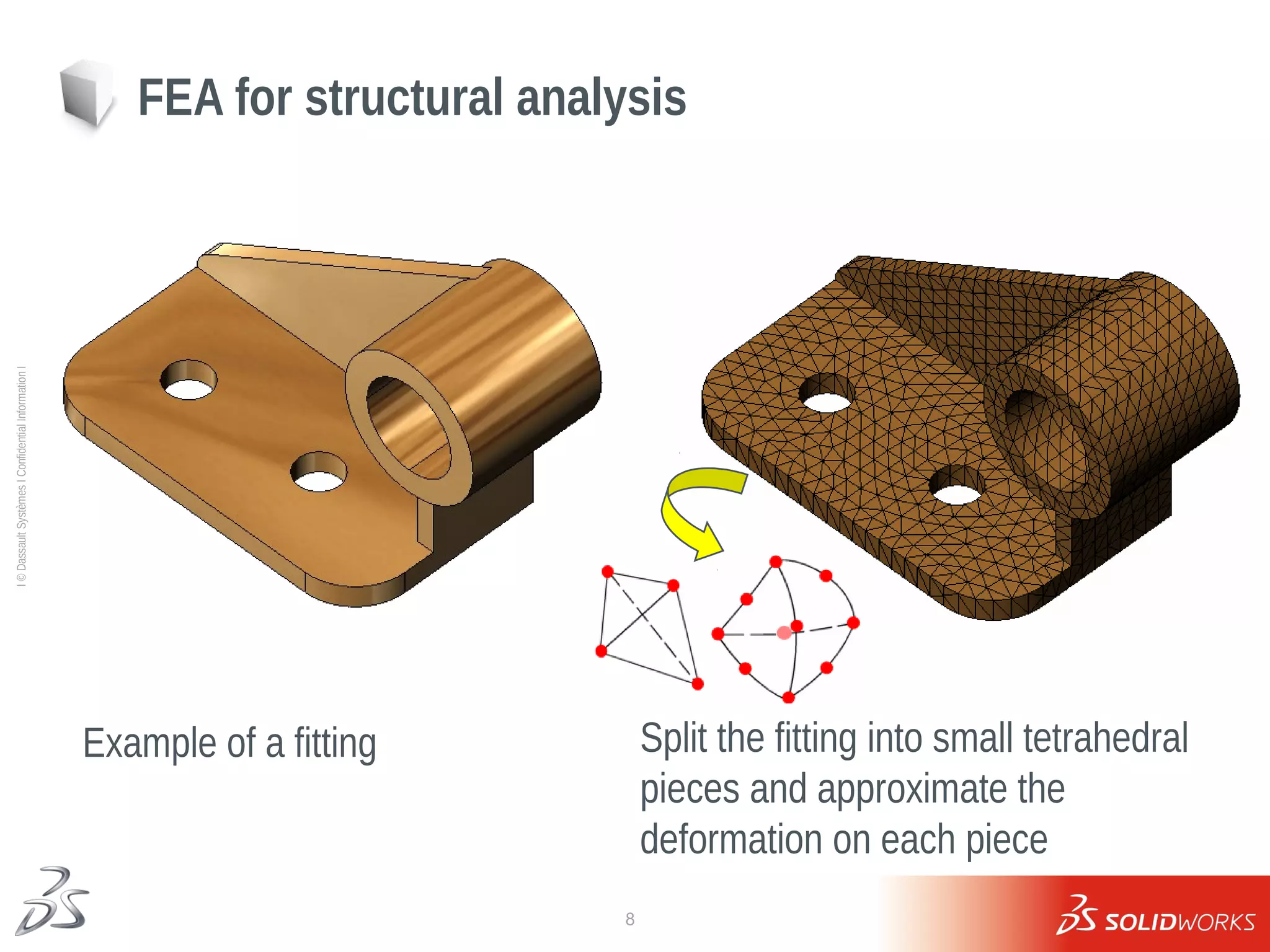

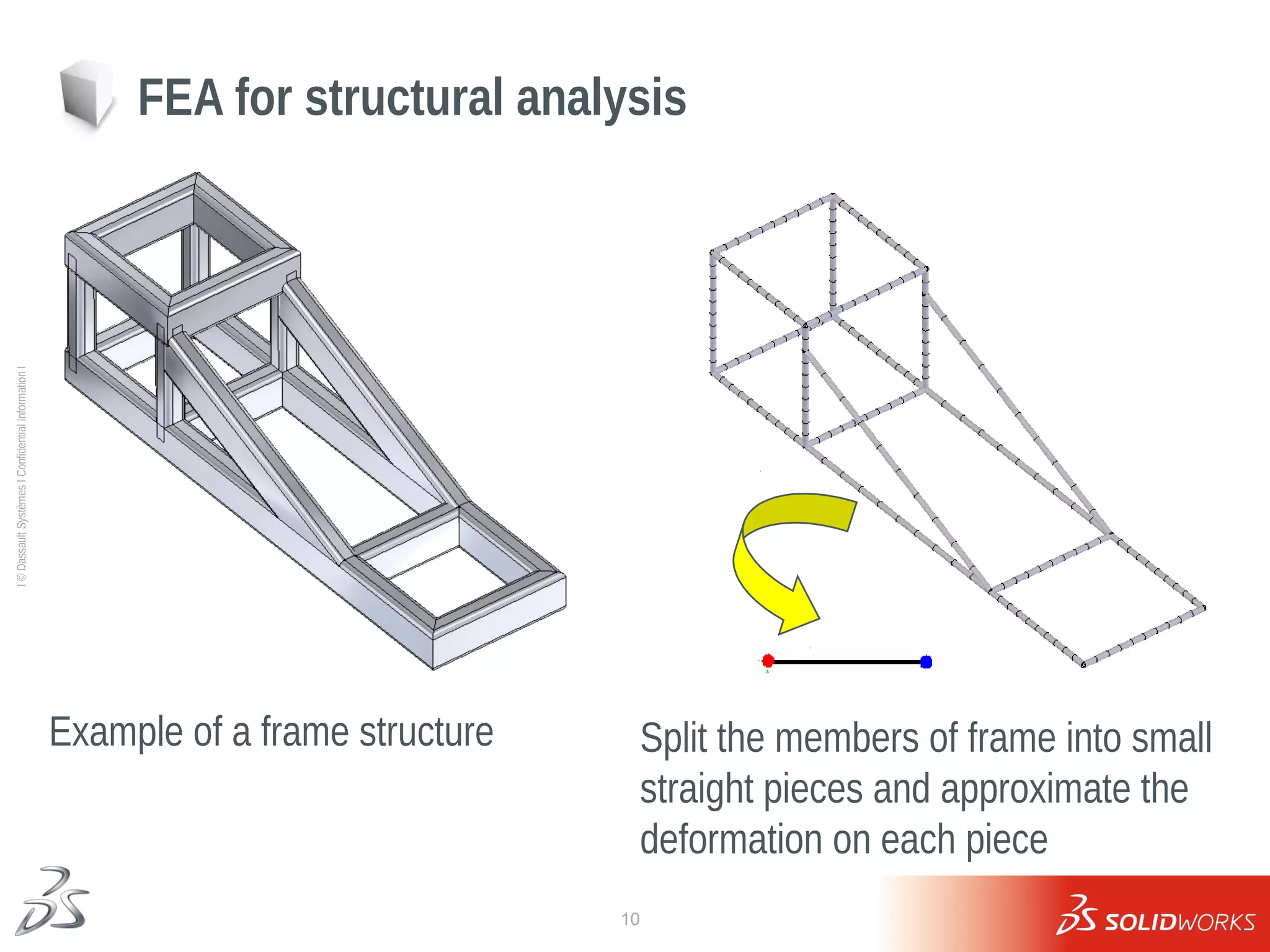

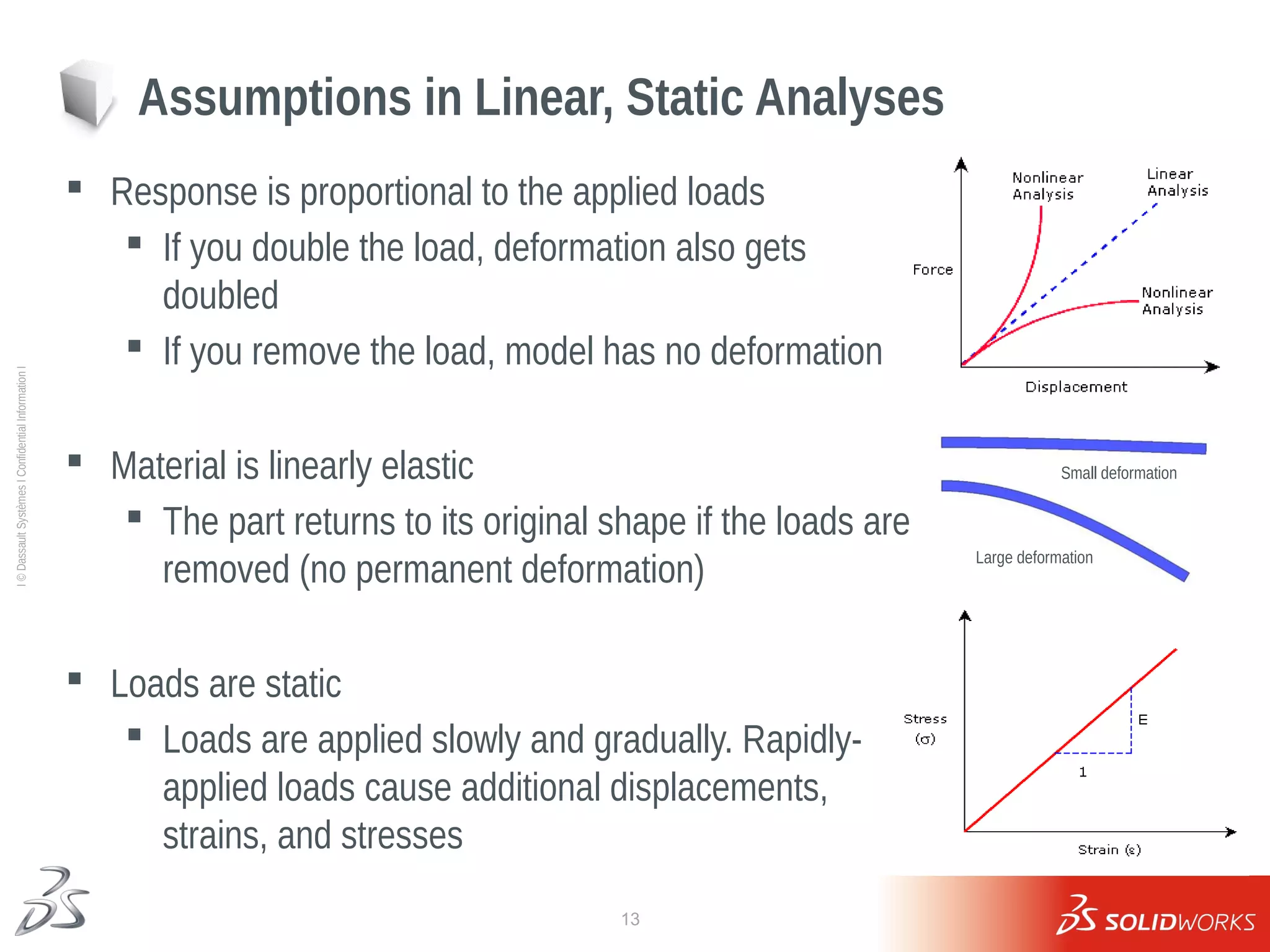

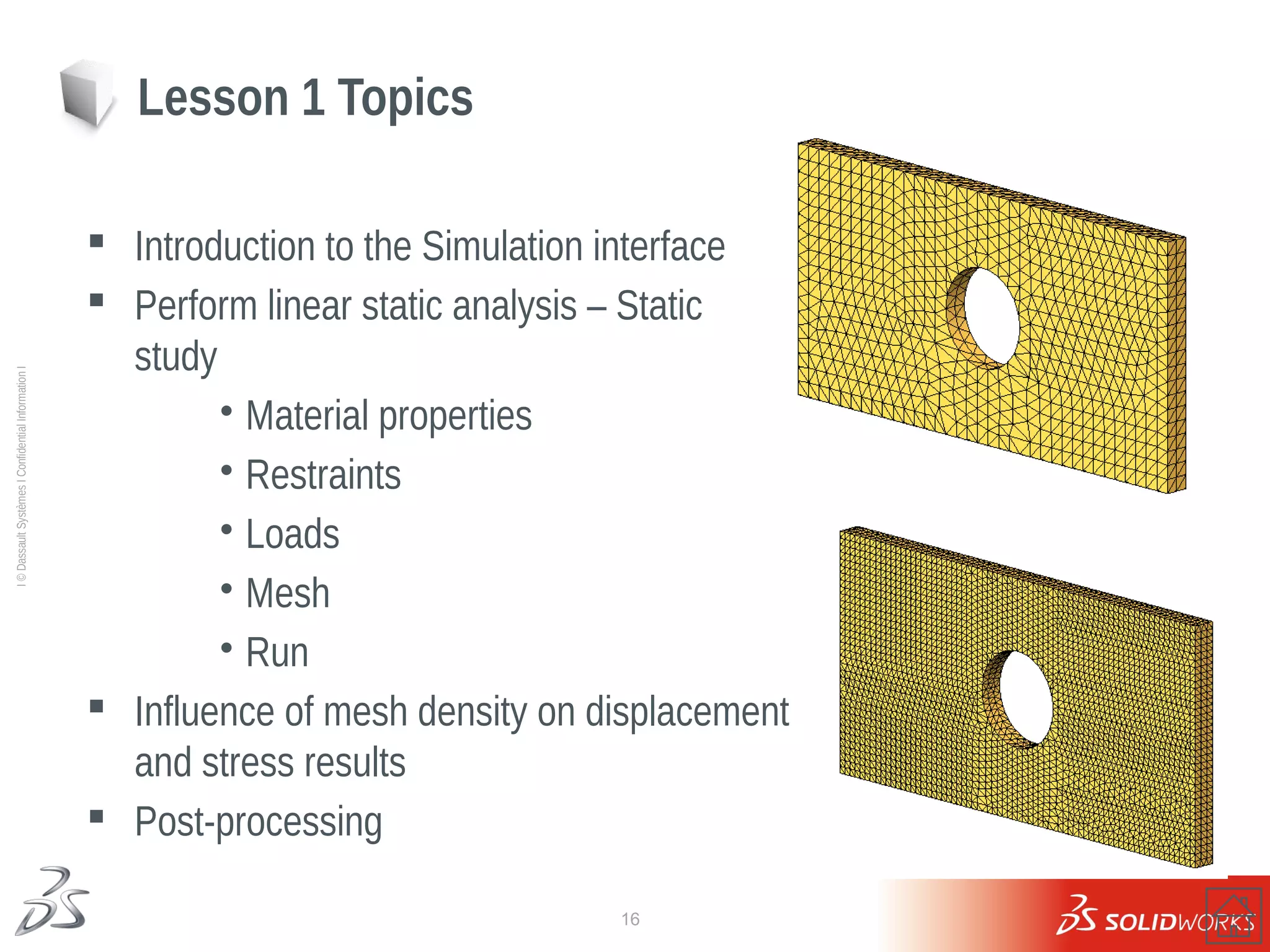

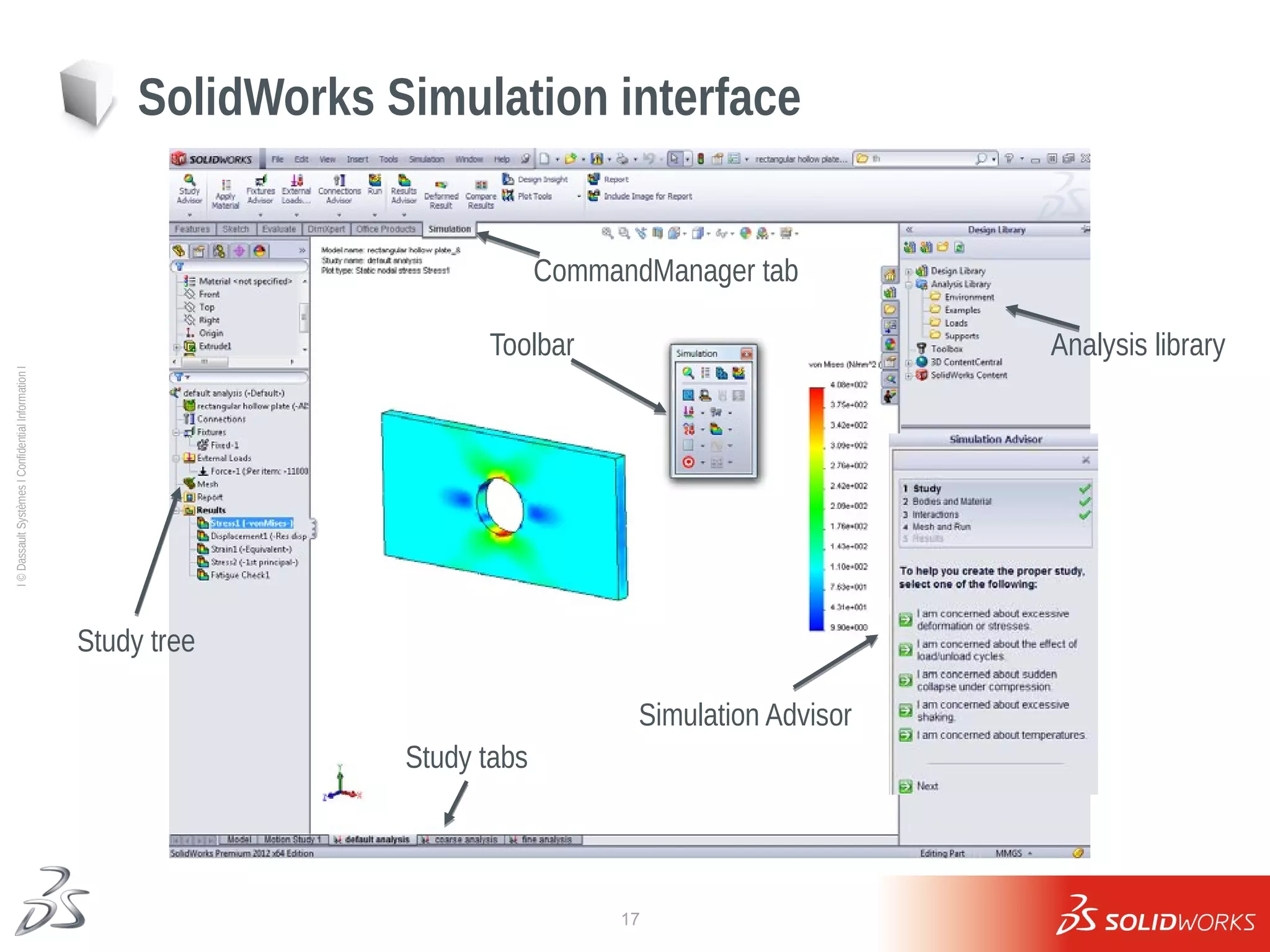

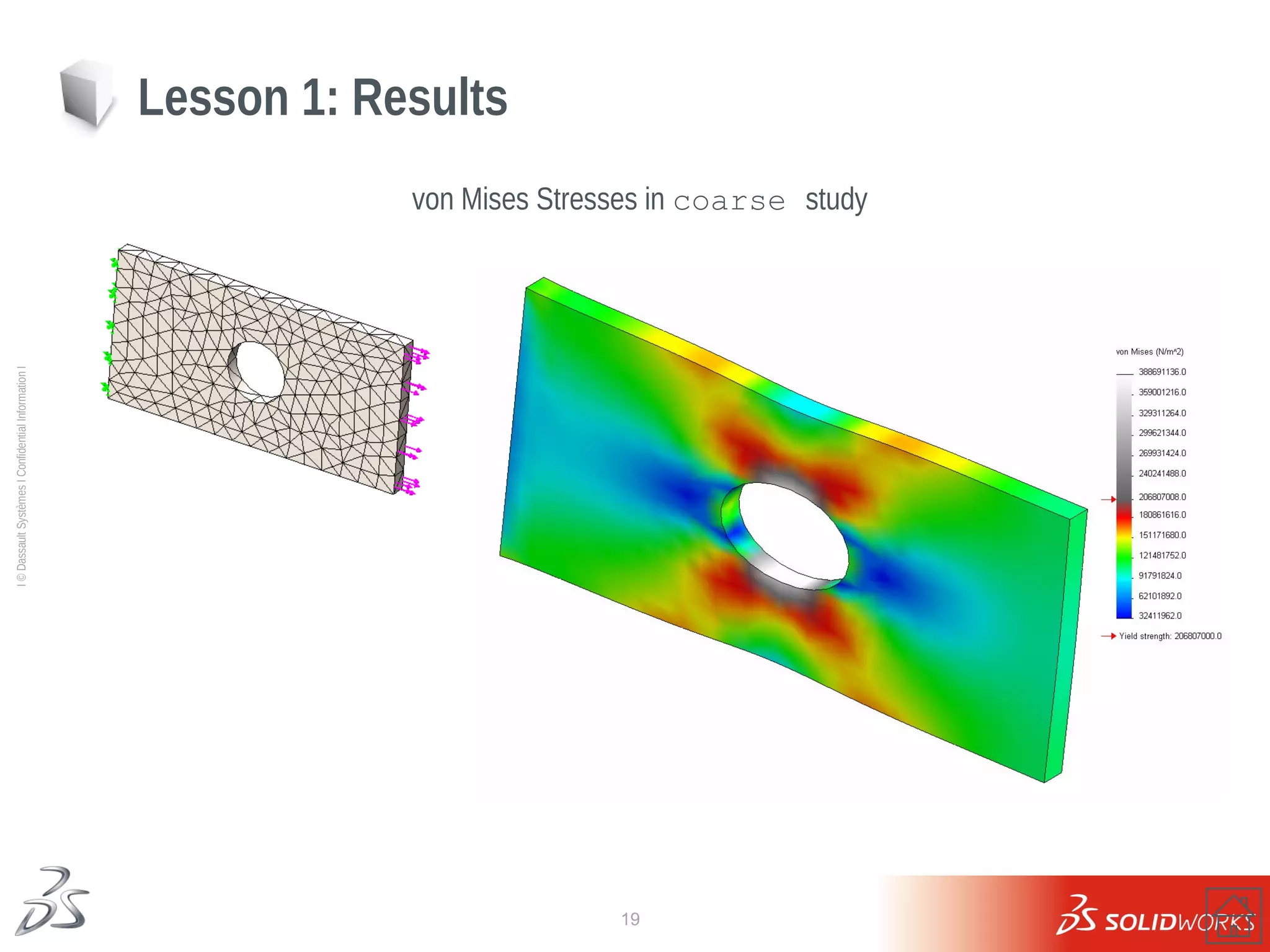

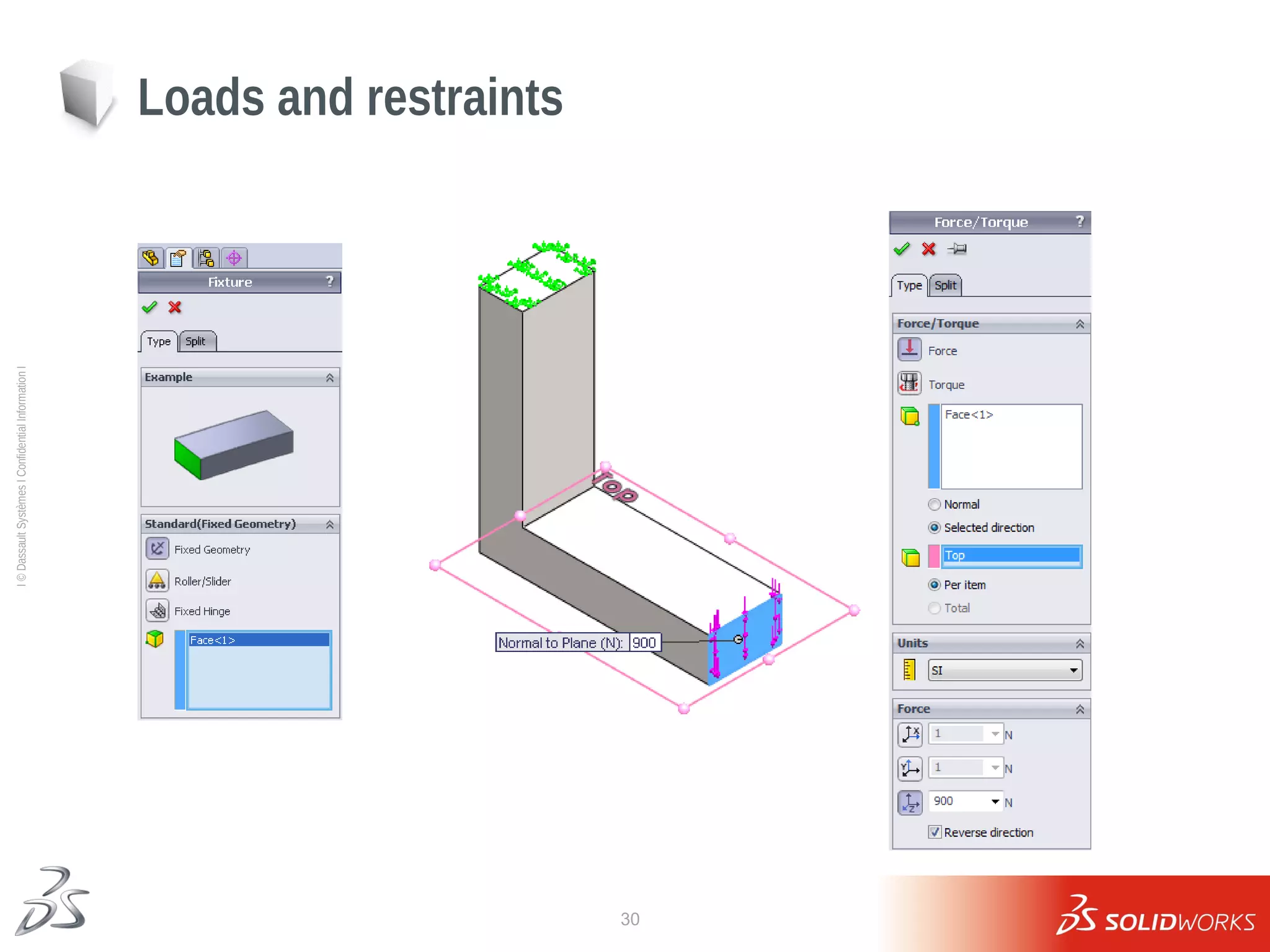

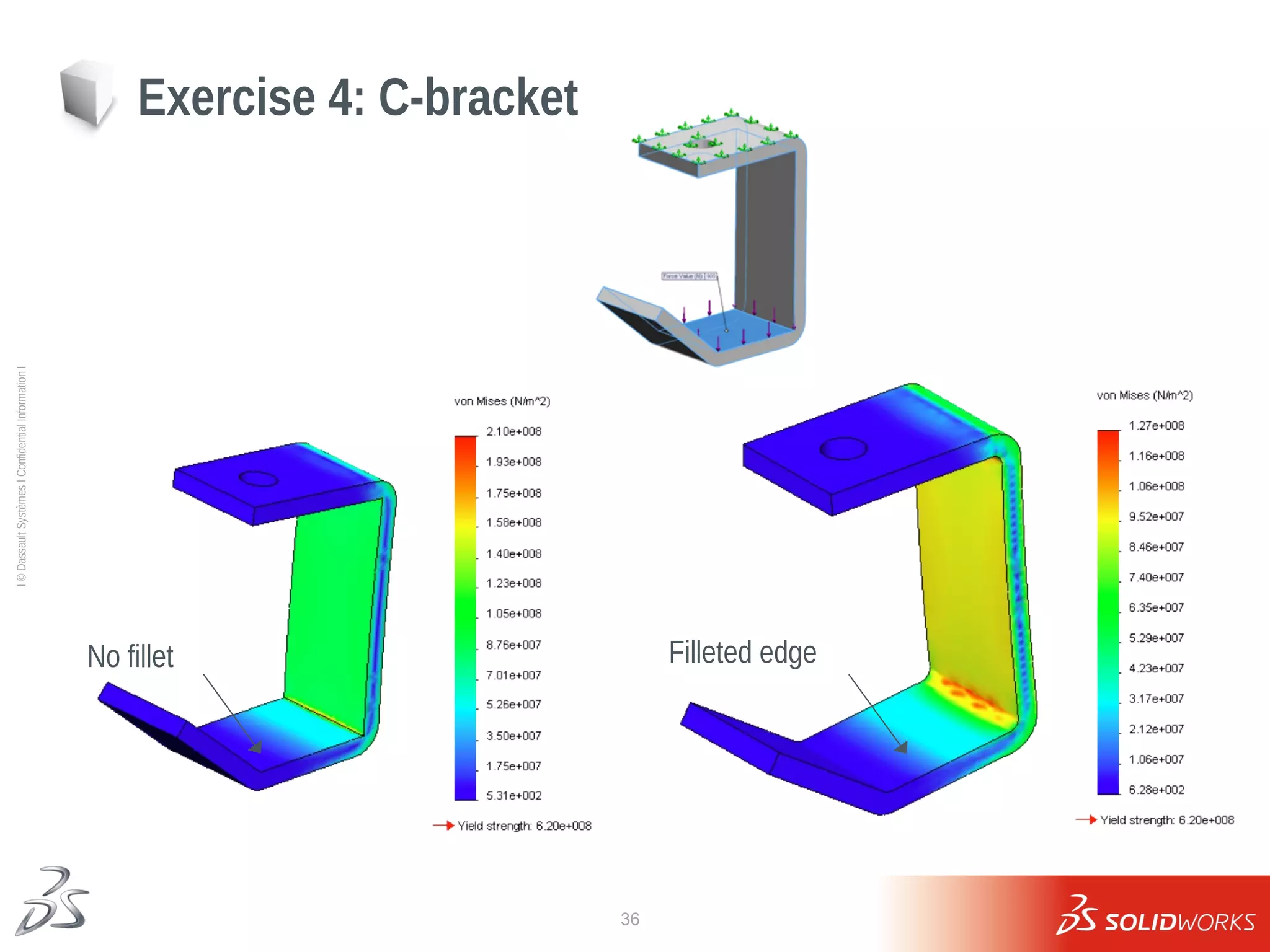

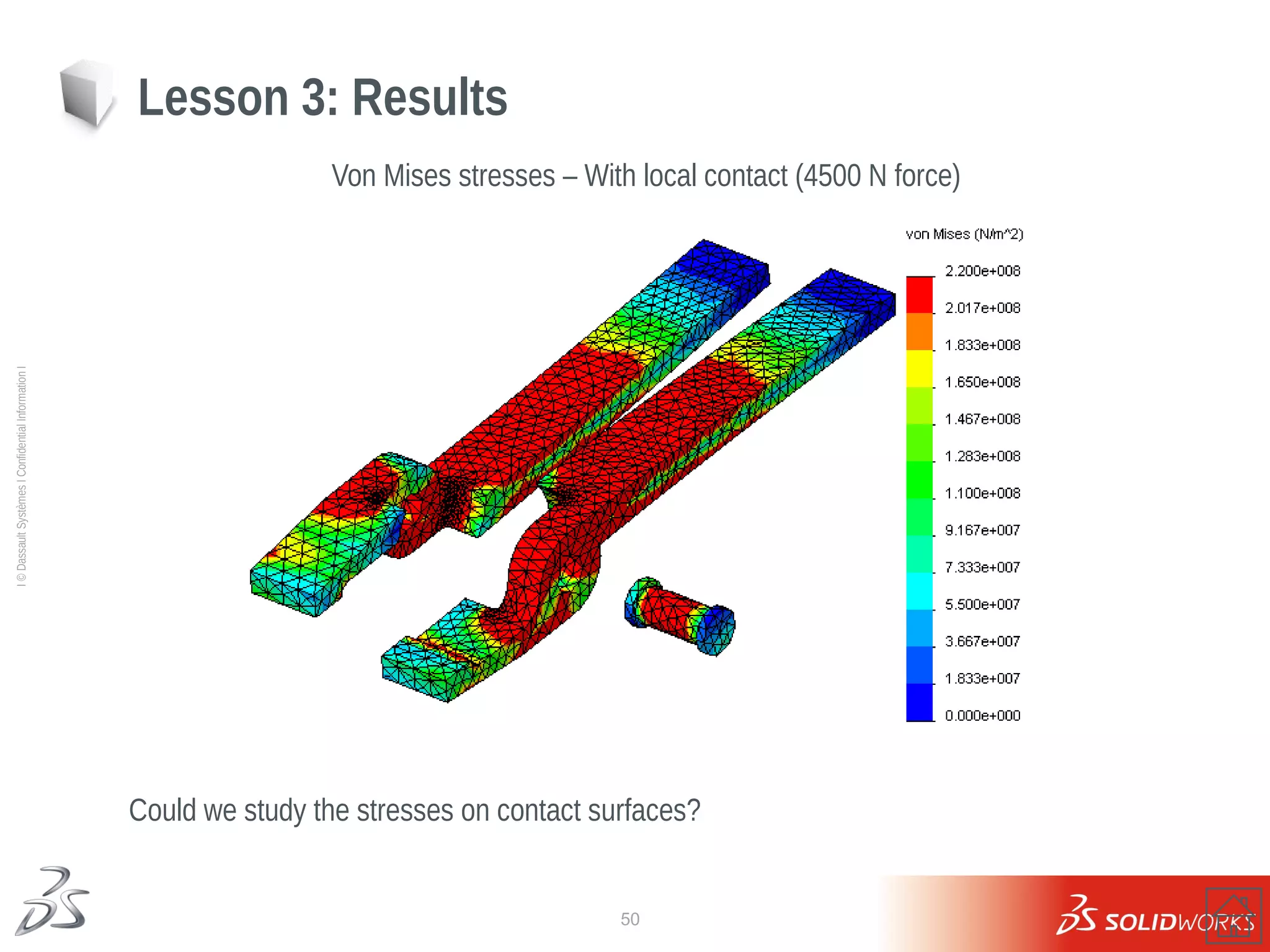

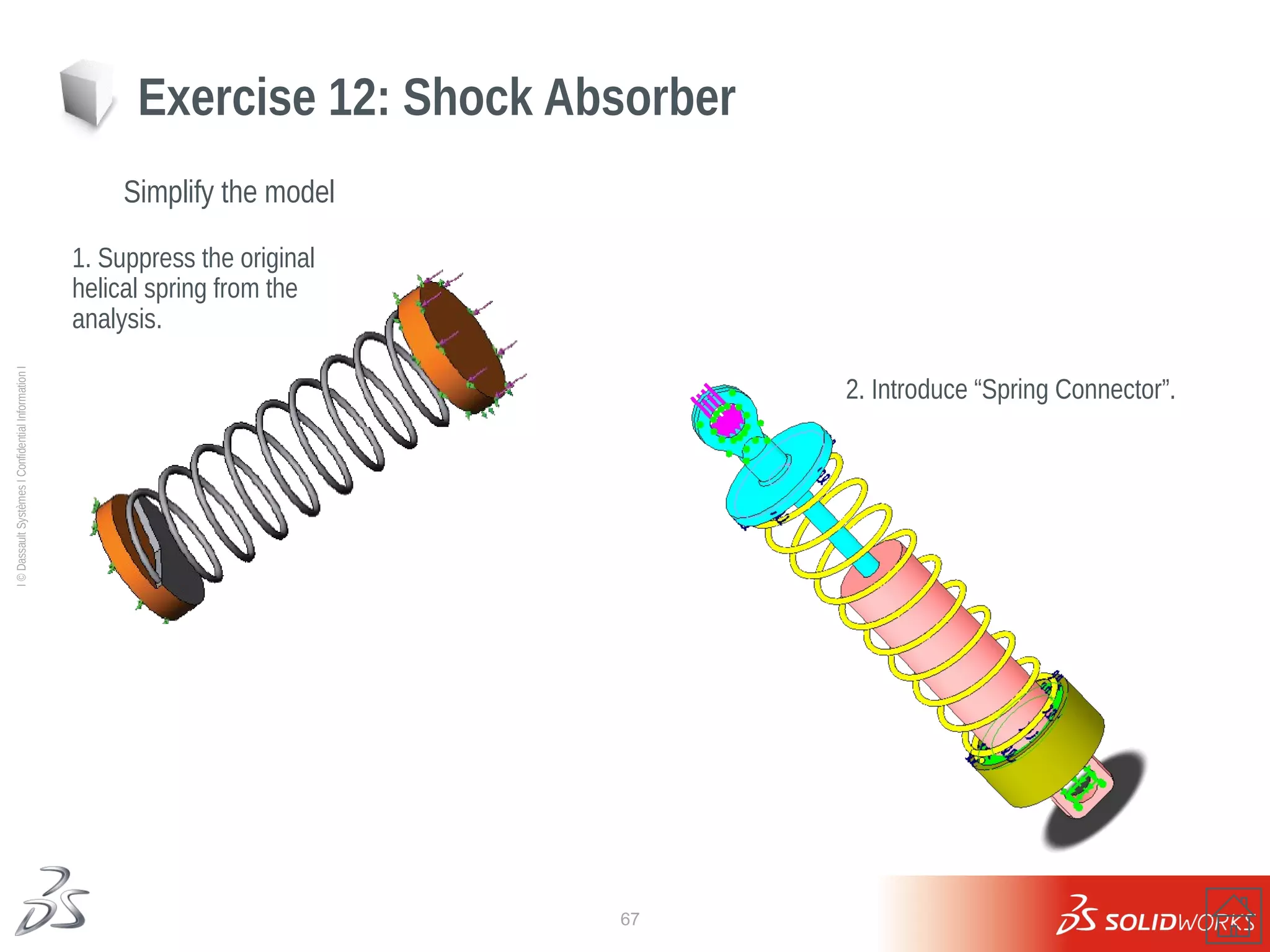

This document provides an overview of SolidWorks Simulation training. It discusses various topics that will be covered in the lessons including linear static analysis, meshing, boundary conditions, stress concentrations, assembly analysis with contact, symmetrical assemblies, and free self-equilibrated assemblies. Example models and exercises are presented to demonstrate key concepts. The goal is to introduce the simulation process and tools to help validate part and assembly designs.